Work order management is the systematic system where, each customer’s requirements are manage to processing in the manufacturing process using the internal work order.

What is work order?

Generally, our understanding about work order is !, the work order is an order that we receive from customer for purchasing goods or services. Ok but its not complete sense, that may also use for internal management, however the content of the W.O. will be little different. Because the work order is planning of order from customer ( for production lines, internal marketing department is customer) and marketing mix.

The drafting of customer requirements are order by marketing to production lines. And with all technical details merged in as additional detailed document is work order by planning team to producing material. See detailed information.

Definition of work order

Work order is structural planning document describe and managing / producing the product or services as per customer requirements.

Why prepared work order for production?

To do list:

- Structural planning of each requirements of customers

- Managing resources, machinery, equipment & time as per unit capability

- Setup customer order’s order priority as per resources availability and delivery requirements.

- Preparation of delivery schedule as per customer needs.

- Management and engagement of resources.

- Effective managing production lines and traceability of each product in in-process.

- For Documented processing by systematic methods

- To establish simple communication method and documentation

Responsibility

The responsibility for preparation, insert and follow up is managed by appropriate departments, the marketing team is responsible for collecting information from customers for making a draft order for production lines, hence production planning team is prepared technical requirements documents, communicate with quality for required testing, and also with marketing team for further specifications likes packaging and delivery requirements. The production and sequence processes lines are follow the work order, so the responsibility for work order is managed as appropriate assigned tasks & requirements.

How to prepare work order?

Process Stage:

- Collecting information from customers for technical, specifications and special characteristics requirements, end application requirements and details. = marketing

- Preparation of draft requirements of customer’s requirements. = Marketing

- Verification of raw materials and bill of materials at appropriate locations. = Production planning

- Understand customer specific and technical requirements, discussion with quality team for each product requirements = Production planning

- Discussion with management for received order from marketing and further requirements = Production planning

- Communication with customer for further details as production planning requested = Marketing

- Verify current condition of machinery, equipment and resources engagement with other orders = Production planning

- Verify time cycles, machine / process parameters and criteria for particular product = Production planning and production lines

- Bill of materials arrangement, resources indexing and procurement = production lines

- Document all the stages and processes requirements for producing materials as per product standards, machine, equipment and resources availability / scheduling the product for production lines = production planning

- Verification and approvals. Documentation and distribution at related department

Processing

The general procedure of the preparation and insert work order in production lines is, receiving orders from customers by marketing and provides detailed information to production planning team for preparation of work order. The details received by planning department are used for initial setup of work orders and verification of raw materials and current status of production lines. And on base of verification, time cycle of production process of particular product and engagement of resources are main factors for planning of work order.

The management team is provides the guidelines and procedures for managing each concern tasks that covered above mentioned stages.

The production planning team is prepared work order as per above process and procedure defined, the work order format (Standard format as per internal management system, recommended) is prepared by production planning department and distribute in related department for further actions.

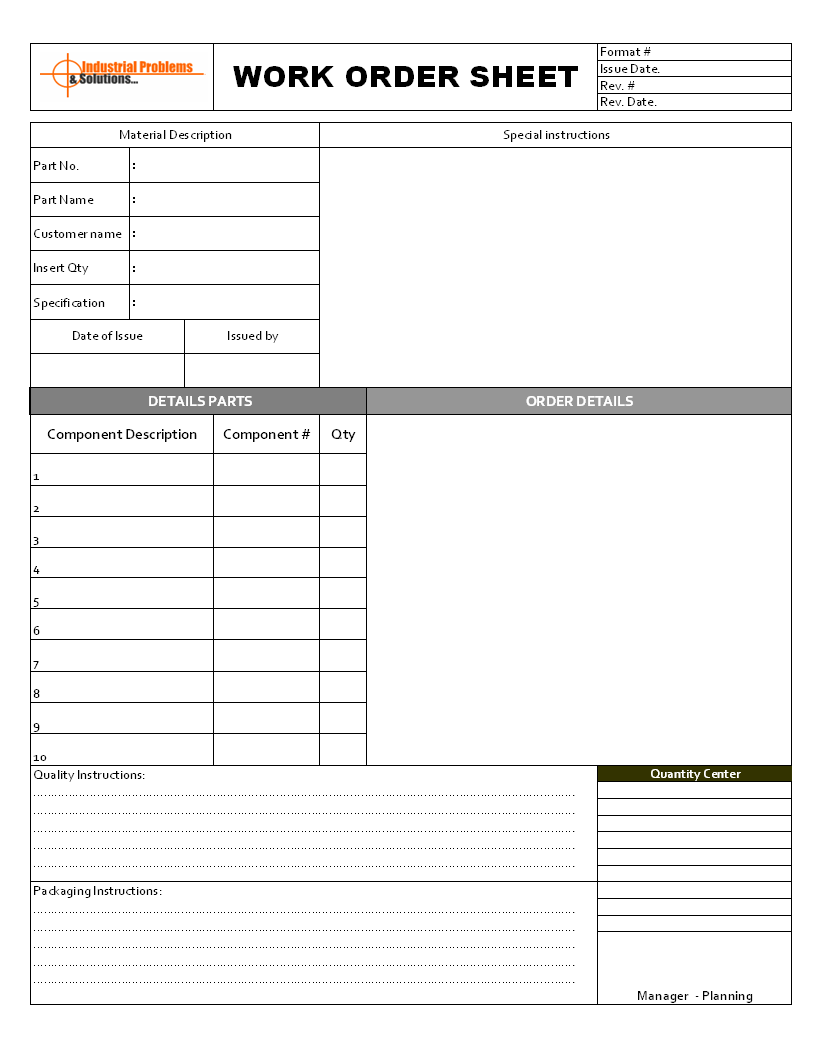

See picture below, the work order sheet format as example of engineering industry for education purpose:

————————————————————

Download format in word document | Excel Sheet | PDF format