Vendor Approval Procedure and management

The purpose of the procedure and management is to determine method of approvals and control to compliance and requirement of quality products.

To establish the procedure of vendor approval process and management to top quality product selection, approval, appraisal and management of supplier of material, services and concern processes in procurement of manufacturing processes. In vendor approvals and management procedure established from vendor enquiry to approvals and management for procure quality product from supplier to compliance of end application requirements. The system helps to maintain the stages of the vendor approval and control management of supplier by defined systematic method of selection and approval with evaluation of the each supplier individual. The system also covered outsider processes and services used in relation to the manufacturing processes, supporting processes and civil, fix assets concern work of the company.

Vendor approval authorities assigned by management to procurement manager with involvement of management advice, all the vendor approval process is conducted according to the vendor approval procedure, procurement manager is responsible to establish system and follow and ensure it is properly followed by department peoples, hence vendor management is responsibilities of the all concern managers, employees who work with vendors, communicate and in procurement process involved.

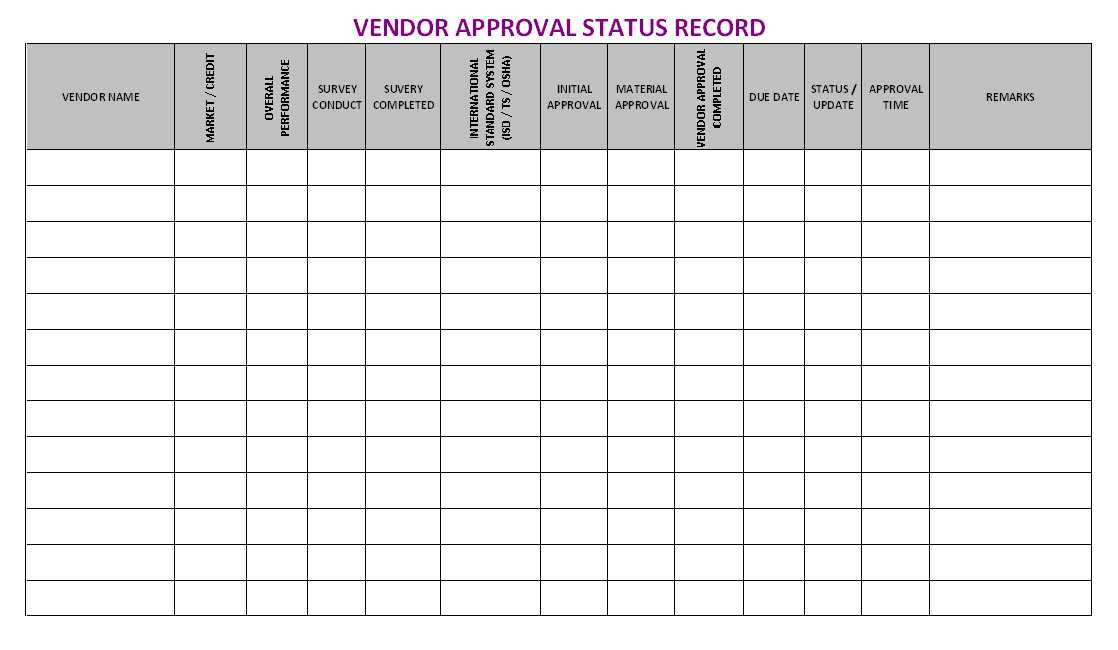

All the vendors should be classified by the management which are under orientation and approval processes, as per company requirement vendor classification are maintained, the classifications are conducted on base of the review which frequency can be monthly or quarterly as per material requirements and supplies. Some most important vendor which requirements are critical to the manufacturing unit and need to put on priority for the implementation, hence some vendors are qualified on base of the analysis of the previous performance of the supplies, those kind of vendor’s are approval process taken on base of the sampling inspection, schedules of visits at the vendor’s premises, if the inspection processes are not completed that all the supplies monitored by management. All vendors implementation, approval process stages and other concern information are conducted which indicate vendor approval status sheet, in the vendor approval status sheet or records are established and maintain for the monitoring and controlling vendor activities and supplies, see below picture of vendor approval status record:

All vendor approvals are conducted on base of the material testing, inspection on some basic activities like delivery, product specifications, material quality grading and others are covered in evaluation of vendor. For the vendor approval some major requirements are as below:

- On time Delivery

- Product / material / Part quality

- Services / Sales after services

Vendor approval process is arranging the monitoring on above three major factors are core requirements to fulfill satisfactory to approval of vendor. Vendor approval are conducted on base of the rating as per company defined for specified level, in case any vendor achieve low than specified level that will be disqualified for the approval and terminate the contacts for at least of one year of given the time period for the improve it system for acceptable for approval.

For vendor approval, company is managing vendor wise filing system to possible monitoring and controls over purchasing & approval processes. In case required to visit vendor end for the inspecting the field level for the auditing system that company should arrange the visit and identify non conformity for vendor quality improvement.

———————————————————————–

Download Format in word document | Excel sheet | PDF format

Download vendor approval status record

———————————————————————–