Tools calibration and control system

Tools calibration and control system is the process to define the calibration and control by monitoring, measurements and controls by structural procedure.

Tools calibration and controls system is process through possible to define the calibration and controls to defined the measurements system, adequate monitoring system and define monitoring and frequency of the monitoring, identification of the control measure for the proper controls over each tool by systematic ways or procedures. Tools are used in the manufacturing activities, quality assurances and quality controls to ensure the product quality, improper tools or defective tools impacting on the product quality that is very important each tools should proper calibrated and certified for the used in the each activities in the company. Calibration of tools is the process where all tools are in used of manufacturing activities, quality & supporting activities to engage directly or indirectly with processes and quality management.

The tools calibration and control system is covers all the calibration and control requirements, measurements and monitoring with engaged equipment, devices and instruments through ensure the tools accuracy and functionally approved to perform in the concern activities. Calibration of tools is conducted by general manager or quality manager to ensure that all the defined measurements, monitoring equipments and monitoring system is proper verified and proceeding accordingly procedure is defined, concern employees are conducting the processes of measurements and monitoring for the calibration processes. Calibration process is conducting by quality engineers or by third party which accreditation for calibration process and tools calibration.

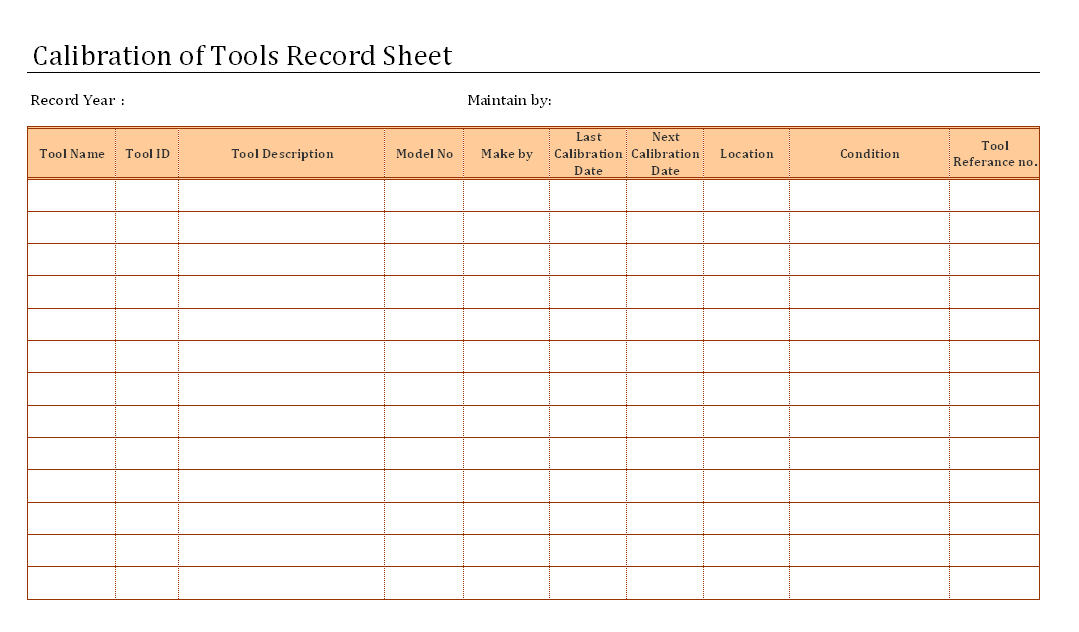

Quality engineer is responsible for the calibration and control system for assuring all the tools and calibration instruments identification, storage and handling are properly manage. All the tools and its calibration process are conducted under the quality engineer observations and also information, records are established, maintain and updated. Generally quality engineer is conducting the information of the calibration of tools which is conducted during the calibration processes or incoming tools for calibrations processes see picture below for the record of the calibration of tools:

Calibration of tools are conducted by quality engineers or third party calibration service providers, in case of the third party calibration service providers must provide calibration certificate on return of calibration process, the calibration certificate are conducted by quality engineer and attached with particular tool history records which is maintained and update periodically or on after calibration process to appropriate process, the calibration process is conducted when the quality engineer is identify tool for the calibration as per standard requirements of tools to used in manufacturing and supporting activities. All the calibrated tools are manage separately by proper labeled or stickers with brief information about calibrations, due date of calibration and other important information.

In case of the failure or non compliance is identified during the calibration of tools that tool will not in used for any processes, failure or tolerance in the measurements, damage or upon unacceptable level tools are manage separate for the further actions and same the records are maintain, and each tool which calibrated are issued with certificate for being used in regular processes.

Tools calibration and control system documentation kept during the entire activity that can be calibration request notes, calibration of tools records, calibration certificate, tools history cards and approved calibration service provider list along with quality department.

—————————————————————

Download format in word document | Excel Sheet | PDF format

Calibration of tools record sheet

—————————————————————