Quality assurance error report

Quality assurance is pre-planning for manufacturing product to avoiding mistakes or product’s defect during processes, but some time happen that any planning are inserting mistakes that mostly happen in beginning of any product first impletion or enhancement of the product. During modifications some experimental planning raises quality assurance errors. But due to those mistakes are making product perfect, after all failure is starting of success.

Quality assurance is pre-planning for the product quality hence mostly samples testing and other primary testing makes its perfect but during the mass production there are possibilities are raised of failures, hence quality assurance error report is required to manage those errors, find out root cause and immediate correction action and preventive actions are possible to places at planned areas.

Quality assurance planning, monitoring and reporting are done by quality assurance engineers in guidance of quality assurance manager, quality assurance error reporting are manage by quality assurance engineering team that all the required solutions are done in line with priority of the errors.

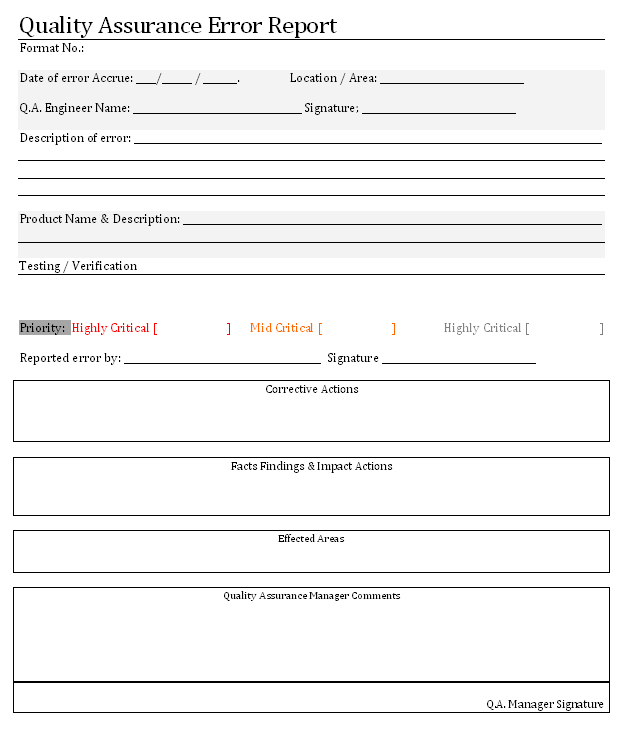

Quality assurance error report is very important part of the quality assurance, due to quality assurances product quality and its reliability are depends hence quality assurance’s any mistakes can loss company reputation. Hence to consider serious requirement of quality assurance error report here given example format as below.

In the quality assurance error reporting quality assurance error date and its specific areas are need to mention in the report and name of the quality assurance engineer name to find out root cause of mistakes.

To find out root cause required full details of the error identified on which product and what is product types with description of application, standards of product. On product which types of testing required and what could verification done are need to mention in quality assurance error report.

During the analysis of information and corrective actions, required to focus on the basic requirements of the error like what is priority or the error, if the low critical category mistakes can solve after all high error that directly and immediate effects on product quality.

Considering the issues of the quality assurance errors, immediate corrective actions are need to take and immediate root cause of the error are need to find for impact or corrective actions are comes on effects. There are also need to consider how many areas of the company like production, planning, quality etc.. Directly effect to pre- intimation is possible to access corrections.

EXAMPLES, SAMPLES & FORMATS