Production hold process

Production hold process is conducted for discontinues mass production on identification of defects in product or in manufacturing processes.

Production hold process is very important and necessary process for production lines, this process is conducted and controlled over production lines that rose when any production process mistakes, error or product having defects are identified during the quality inspection or regular inspection by concern supervisor. This process is conducted for discontinues mass production i.e. completely stop the production running in manufacturing unit to controls over the processes that producing materials with low quality or production processes are making a defects in the product that needs to stop the production lines for corrective actions.

Production hold process is managed for the verification of the defects occurred due to miss configuration of the manufacturing processes, machinery and equipment, raw material defect identified during manufacturing processes by concern operators or supervisors, defective production processes or stages or any human errors can be create the production processes. The production processes hold is occurred due to following reasons generally:

- In processes or process stages having a miss configuration, sequences and interaction miss match can occurred process disturbance.

- Due to Raw material defects can cause production hold, the raw material defect is serious because it can cause whole lot / batch or full of produced materials can be reject so its important that immediate production hold can save materials and costing affects.

- In case of human error in manufacturing like miss configuration, parameters change or wrong setup, wrong product loaded or any other concern error are occurred due to human error are needs to immediate production hold.

- Machine mistakes, error or defects with product, low quality product producing etc.., are machine errors that happened due to hardware, mechanical mistakes that needs to immediate actions on it, hence the machine mistakes identification and for solution needs to immediate stop the processes.

- During the material handling there are some mistakes, miss management, wrong materials loading or any defects occurred with materials during loading – unloading needs to stop the production lines for correction, but it’s happened for short period.

- Parameters and other setup error are conducted for verification when any product having minor defects is identified, the process is conducted for parameters rearrangement or primary setup modification needs to complete shutdown the production required.

- Some other reasons that not listing in regular reasons are also affecting production lines, so its all depends on the reasons that time consuming and other concern.

The general reasons behind production hold are given above, there is also possibility some other reasons that occurred and needs to production needs to immediate shutdown temperately. In the manufacturing processes quality inspection teams are frequently monitoring and inspecting product to take the sample as frequency defined by quality department for verification and inspecting product as per standards, technical and customer specific requirements, during the inspection processes, in case the product having any defects that can be minor or major there is no difference the production lines are needs to immediate hold for the verification and identification of the defect source causes, immediate corrective and preventive action to controls over production processes and manage / improve quality of product. The system is managed fully controlled that needs to managed work instructions and procedure that help to manage each process accurately, but any mistakes can cause production hold which is direct affecting product costing.

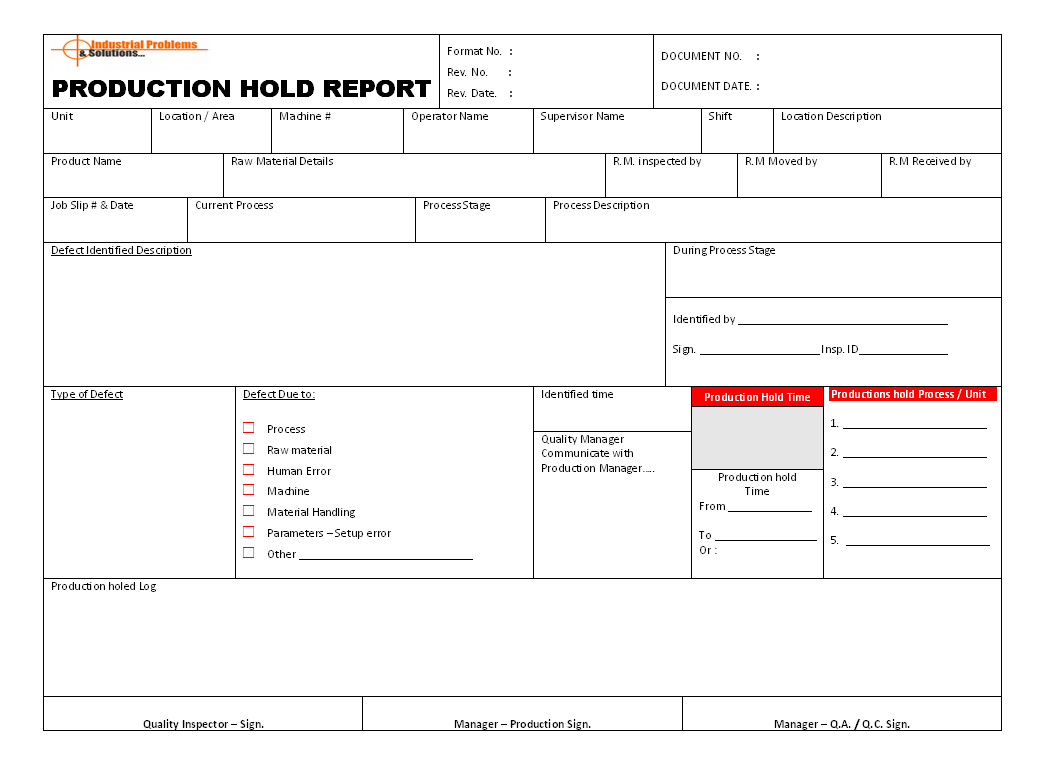

Production hold process is established by production manager to communicate with quality manager, and production manager is responsible for production and its concern activity that maintain quality of product as per standards requirements are prime responsibility of production management hence the concern procedures deployment and aware concern peoples about each requirements, work instructions and guidelines to peoples for conducing tasks that assigned by production manager, and also responsible for monitoring and controls over processes are managed for producing materials. The production manager is communicate with concern supervisor for materials hold and prepared document or assigned documentation work to qualified supervisor, the format that used for recording production hold process is production hold report, see picture below given as example format of production hold report, here given for education purpose:

Production hold report format is used for recording information of production hold process, the activity that conducted during the production hold are recorded, the information of the production hold are managed, there are some important requirements of reporting are managed and update accordingly like location of the production hold is occurred and areas, machine and operators details, product details which is running in current process stages, the product is being under manufacturing reference slip number that job slip number and its details, defect identification details, type of defects and production hold times etc.., are mentioned in production hold report to reporting concern manager. The documentation is maintained in production department, its storage and disposal are handled as per standards documentation system.

——————————————————————————-

Download format in word document | Excel Sheet | PDF format

Production hold report

——————————————————————————-