Production control and system management

To provide a method for ensure that production processes are conducts under controlled conditions, managing all activities as documented procedures and system approach.

Production control and system management purpose is provides a method to ensure all the manufacturing, production processes, used machinery and equipment and concern activities are managed systematical ways and carried out under controlled conditions. The process describes all the controlled conditions for production is carried out & management system to provide the duties, responsibilities as workplaces, machinery, equipment and activities are involved.

Production controls by system management ultimate goal to provides and ensure all customer requirements, understanding the customer specifications, characteristics of products by records of each order placed. All the information should recorded as purchase indents of customers and specification requirements are manage by marketing team. To controls over the processes that required to marketing team is insert the product requirements in to job order and scheduled materials to appropriate machinery and unit. Designing team is preparing the design of the product for incorporating requirements with specifications, tolerances of product as acceptance level. Planning is responsible to preparation of the material, machinery, equipment and processes sequences to move the material from raw material to production along with supporting material i.e. bill of materials as product sequences and interaction requirements of processes, manufacturing requirements and product specifications.

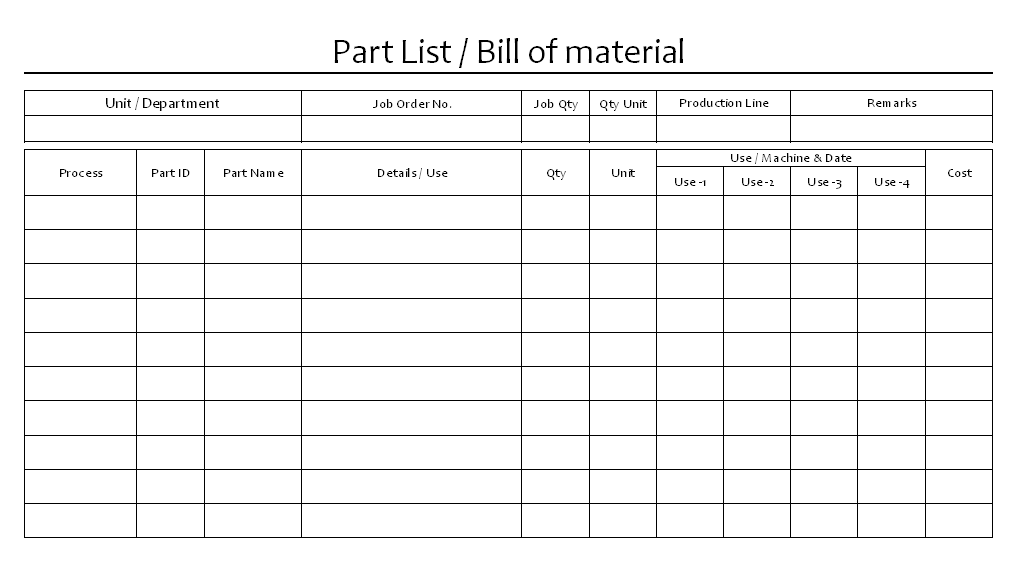

Management planning and control for the production, manufacturing activities through out all the processes stages of manufacturer, the project reviews, job order, work order and its processing, job order system and concern issues documents are maintain to ensure that the customer requirements for product realization are fully understand of each step / requirements before beginning of any task. This can includes the product characteristics / material specifications, customer requirements, technical requirements and specifications and product sizes or parameters that level of acceptances i.e. product tolerances. All the technical / materials specifications and concern tolerances of sizes should mentioned in job order formats and should be issued along with description and same should be verified by production manager. To value added system should be need to preparation of the listing to all preferred part list for manufacturing activities, at facility as requisition of parts, see picture below:

The bill of materials or part list is used in the manufacturing processes as supporting material to producing materials by various processes, in the various processes required all the supporting tools, dies and other materials and parts are proper listed and recorded with set as sequences in the manufacturing processes by planning team and same for the production peoples are aware of the technical used in the manufacturing activities. Technical and process documentation is subject to the document control process which is separately manage and controlled by the management to maintain system in the company. The materials is used in the facilities should be verified with the quality standards and equipment to ensure that the products is being produced is comply the requirements of the high standards and met the requirements of end application.

In manufacturing process support equipment for the quality controls & other production processes required measuring equipment, devices and instruments are conducted, listed and proper verified before used and should be properly controlled. For monitoring and measuring devices are controlled under calibration procedures, verified by quality control teams or outside by third party and each due should be maintenance with accuracy maintained for the equipment calibration. All product requirements, controls are maintained for the final quality product requirements.

Production control and its system management is works under the control parameters are defined and control measures that required to proper production specific requirements, process carries out production under controlled conditions. The control need to involve the basic requirements.

- The information and description of the characteristics, specification details of the product should b clearly visible, involved and should be met the expectations of customer requirements.

- All the records, required standard operating systems and procedures should be in line with the working process, fully written and easy for available to all concern.

- Management should ensure, determine and final equipment, supporting devices to perform best to producing the material with quality and equipment should be best suited for particular materials is being produce in the manufacturing processes.

- Quality control and quality assurance should be determine best suitable testing equipment, devices and instruments to provide best serve to conform product quality and suitability of end application.

All product should be clearly indicated by the proper signs on at the stages of production as well as quality to packaging stages, the materials should be released for the warehouse should be proper quality inspected and labeled for the quality controls, all the authorized signature on the label or documentations is must to determine the product quality. All the product documents and its audits are conducted, all the product specification documents should verify to ensure the product quality and conformity of customer requirements with product.

—————————————————————–

Download Format in Word document | Excel Sheet | PDF format

Bill of material (BOM) / Part list download

—————————————————————–