Process input output management establishment needs to organize process inputs in manufacturing processes to get quality product as output.

Overview

Process input output management system is deploy to managing each manufacturing processes’ inputs for producing materials that is raw materials. As well bill of materials, resources and other supporting tools are organize as input for processes to conducting manufacturing activities by systematic ways. To achieve best quality of product as results / outputs from manufacturing process.

The inputs materials for manufacturing processes are important parts of manufacturing. Hence the materials should be also well inspect, manage as inputs, the verification of process inputs are only the materials verification before loading in processes. But the material process inputs are manage since the materials procuring that outputs are achieve as require to maintain quality.

Standards & technical requirements

The standards requirements and as customer technical requirements to meet end application. The process input output management process establish to compliance requirements of standards of product. as well as technical & specific requirements of customers to meet end applications.

That all tolerances are consider of product dimensions, hence the product inputs are manage accordingly to concern raw materials as input. The process owner is manage the tasks as per input out planning are manage by planning department.

Hence the materials planning team is considering the suppliers / supply to verification which the materials are needs to loading in manufacturing processes. bill materials and other supporting materials are also verify from supplier / supply to ensure the inputs are as requirements of quality. all international standards requirements are comply to assurance of quality of finish product / output of manufacturing processes.

Planning & implementation

Process input output planning are conduct by manufacturing planning department. The quality department is manage quality planning for process inputs and outputs from manufacturing processes. Quality planning for all suppliers and its incoming materials are use in manufacturing processes & supporting processes are verify & inspect.

To ensure the product quality, hence process inputs are verify the materials and plan to input in manufacturing processes. The planning process input held and schedules are prepare and maintain by production department accordingly. The process owner get intimate by planning department as well as quality department to acknowledge the process input program. The quality verification for material quality testing as on raw materials, in process inspection, sampling inspection and final quality inspection as results / output of manufacturing processes.

The documentation for the process input out planning are manage separately by production planning department, and share with production department. The planning department is responsible for managing documents, hence quality department is responsible for verification and inspection of each materials. The needs to loading in manufacturing processes as well in process and outputs from processes.

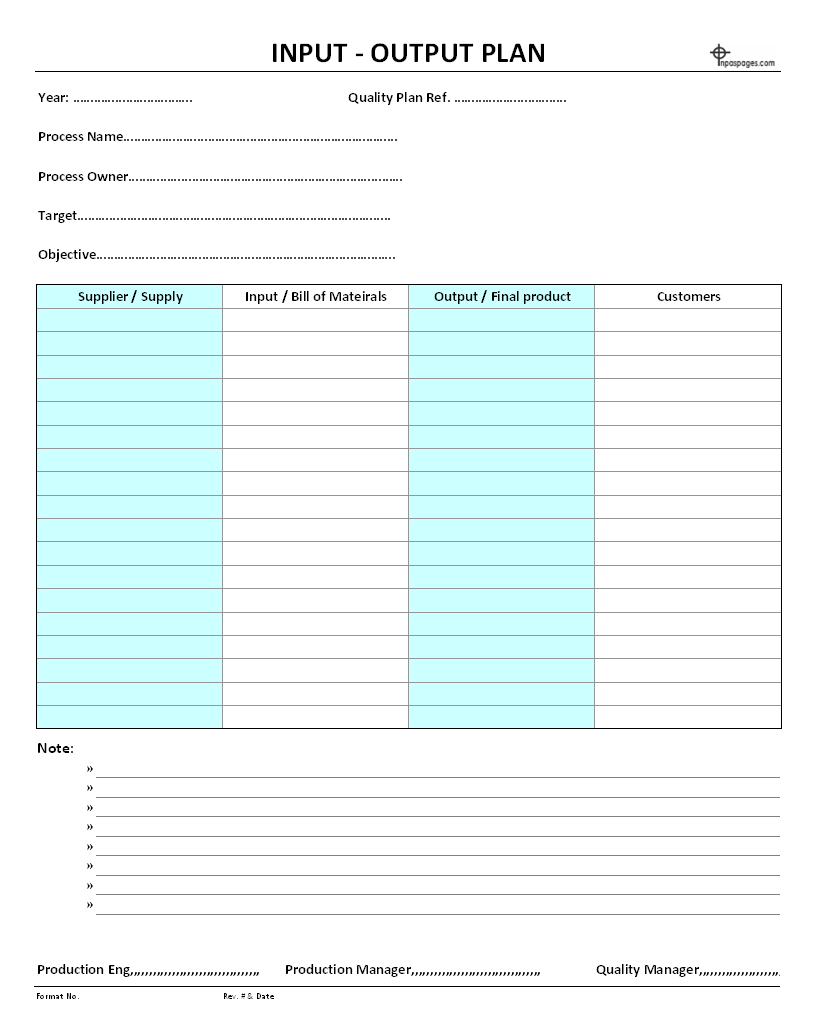

See picture below given as example format of input-output plan format for education purpose:

Process input output plan format

The process input output plan format is use for recording information of planning of production. This process input to producing materials, and planning all process inputs quality verification and inspecting. To ensure output / final product quality as per standards and customer technical requirements.

Input output plan format is use to managing records of each stage of planning to input the materials in production lines to considering requirements of customers. The materials are considering through suppliers for verification and approvals, inputs and outputs to conduct for verification for quality requirements of product. The documentation is manage by planning department hence concern quality records are manage by quality department.

—————————————————————————-

Download format in word document | Excel Sheet | PDF format

Input – output plan

—————————————————————————-