Preventive maintenance schedule: maintenance Task

What is Preventive maintenance schedule?

Preventive maintenance schedule is advance planning for maintenance to eliminate possibility of failure of machine or equipment. It can schedule daily, weekly or half monthly for each machine as on critically. In the preventive maintenance schedule, team set up on priority to consider critical machine or condition.

How to implement Preventive maintenance schedule?

Importance of preventive maintenance in any organization can gives advantage for enhancement in productivity, satisfaction & quality product, financially & much more. Preventive maintenance is completely maintenance task to should perform regular basis to maintain schedules, operations & improvements tasks.

Small scale business are not well aware for schedule maintenance or preventive action to avoid futures possibilities, need to be update small scale & medium scale business people to take in action that preventive maintenance gives gain your business performance as well as financially support too.

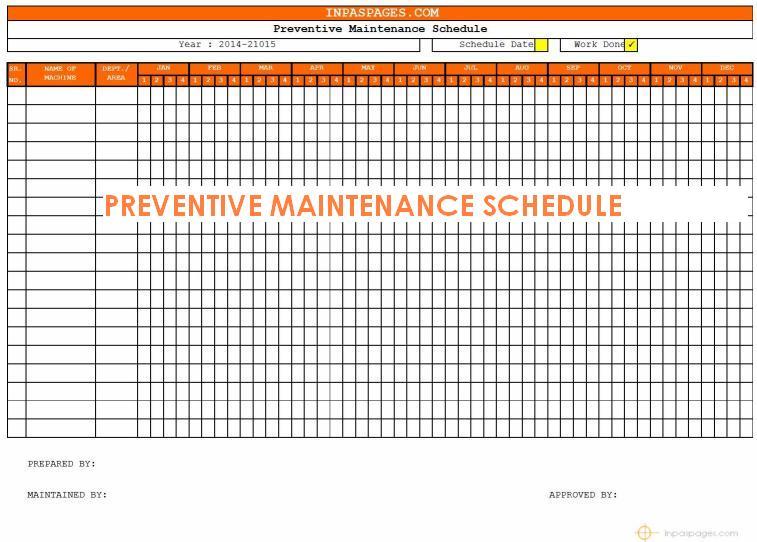

Here we are gives you a template that help to make a schedule for your organization’s machines, you have to just fill up the excel format that ready made preventive maintenance schedule that cover all the machineries at your end.

How to schedule fill up in excel format?

As simple was never before, in excel format you can get the yellow cell that copy where you want to schedule on the “ WEEK OF THE MONTH” can be 1st week, 2nd week, 3rd week and 4th week of the month. Week is much preferable instead actual data as usual can be possible that your scheduled date can’t take machine in maintenance due to load of the production line, to avoid disturb schedule and its track always prefer weeks and same will be fill up right mark when done the job preventive.

Preventive maintenance schedule that single document help to organization tremendously, During the preventive maintenance almost error are expose against maintenance peoples, that mean before the parts expire or more damage possible solution can done without affect production schedules, operations or delays in job orders along with saves a possible damage expenses that you never expected.

Preventive Maintenance & machine life

A strong relation between maintenance & machine life as you know that, regular Cleaning lubrication inspection Tightening program that is part of preventive maintenance that benefits are as below:

- Avoiding a depreciation of the parts which are cruise each others.

- Find out loose wires and loose connections. Loss parts can damage machine or cause serious injury to humans.

- Off course regular oiling, greasing, lubrication maintenance always gives a more life to parts.