Poka Yoke (Mistake Proofing) – Zero Quality Control System (ZQC ) : Zero Defects

Poke yoke is mistake proofing methodology which is basic objective is zero defects approach & also called “zero quality control System”.

Poka Yoke is a Japanese words – “ Yokeru” became “Yoke” which means “to avoid” and “Poka” which means “inadvertent errors” therefore Poka yoke mean – “ avoiding inadvertent error”, but in English this words does not sound effective to correct by some equivalent words like “Mistake Proofing”

Poka Yoke is technique for avoiding mistakes can use in manufacturing process, the goal of which is to eliminate defects to produce quality product. This concept helps to manage where multiple manufacturing, wide range of the products are being producing & difficult to monitoring & controls on the activities, process & elimination of the process treat, poka yoke provides the system through prevent error in their workplace by easy to instruct to workplace’s peoples & implementation.

Poka yoke can implement with the process which possible to identify mistakes, error during the process activities, and step by step implementation of the poka yoke helps to target the error free working environment by the continual monitoring on the each activities that helps to producing the product with best quality. Mistakes / errors can increase values of product that mistake proof system is also consider as costing control in time frame.

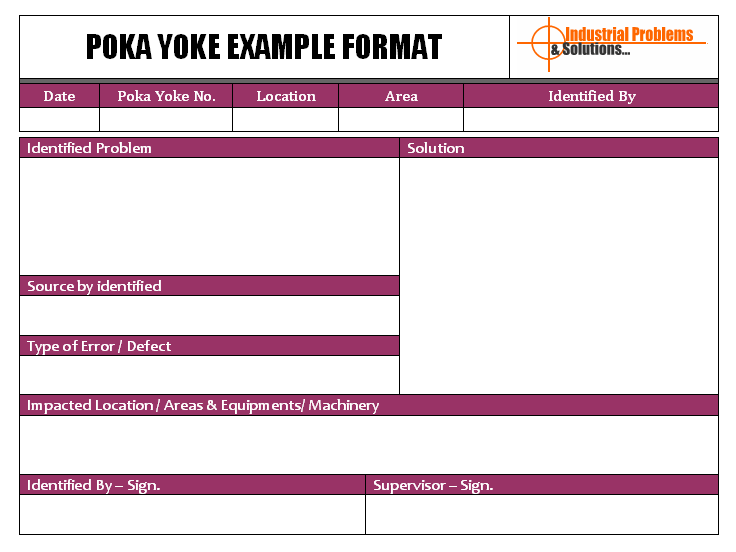

Poka yoke technique is simple for implementation to needs common sense by understanding of the manufacturing process & supporting devices, machinery & equipment can uncontrolled system mean easier to access by concern workmen, easier for operating & manuals with effective monitoring system by operators. Before the operation any treats are identify that need to immediate actions required before mistake harm to system or effect on manufacturing process. For the recording of the poka yoke in the manufacturing unit that need to document which by records are available, see picture below for the document can use for the recording mistake identified:

Record information helps to implement Poka Yoke Technique in the manufacturing unit, base of the record information further locations & areas can easier to detect errors which became defects in products & implementation. By Poka Yoke methodology findings of errors and troubleshooting before become defects.

Poka yoke is methodology which involvement of mechanism in the manufacturing & supporting process that helps to identification & eliminate mistakes to achieve zero defect targets as quality product requirements.

Poka Yoke verification

For manufacturing processes, devices, equipment and machinery proper Poka yoke method is effectively implemented & verification of the each step are taken is enough for the avoiding mistakes are need to verify by simple auditing to ensure the components, devices, tools etc, are at its place & form.

- Verification of each components

- Verification of all parts / tools / die & BOM material

- Verification of process parameters, supporting presents & Functions

- Verification of product tolerance

Her as above given some verification requirements, there are dozen of verification can apply as per product & manufacturing practice. During the verification of Poka Yoke system incase any error, mistake found that need to immediate record problem in log book.

EXAMPLES, SAMPLES & FORMATS

- POKA YOKE IN WORD DOCUMENT DOWNLOAD FREE

- POKA YOKE IN PDF FORMAT DOWNLOAD FREE

- POKA YOKE TEMPLATES DOWNLOAD

- POKA YOKE IN JPEG, PNG FORMAT DOWNLOAD