Planning for product realization

What is Planning for product realization?

Planning for product realization is process method for planning of product realization that is consistent with product development and manufacturing to meet customer requirements.

Overview to planning for product realization

The planning for product realization is important part of product realization. The system is depending on preparation of planning and effective implementation in the organization. Quality assurance team will be developing the planning system for improve product quality. Make sure that, the planning of the product realization should be consistent with the requirements of processes and objectives. The planning is managed for improvement quality of product through implement standard processes for producing materials and supporting processes are covered to sustain.

Implementation of planning for product realization

For effective implementation of the planning needs to manage all operations though proper assignment of duties & responsibility. Organization will build the cross functional team from different departments and functions. Because CFT is recommended for implement of every task in the organization. The team conduct initial require stages such as planning and development of processes for product realization. Planning of product realization should manage to consider quality requirements of product.

The management team should ensure that all inputs and outputs. Team verify that all critical to quality processes should clearly identified. All inputs and outputs of the planning can possible to identify through SIPOC method.

The quality plan / planning should have identified the requirements, and cleared in the documents about objectives at any levels of the manufacturing processes. Manufacturing process identified outputs requirements as per customer technical and specific requirements. The planning sustains the requirement in puts such as materials, resources and services as per final product and end application requirements.

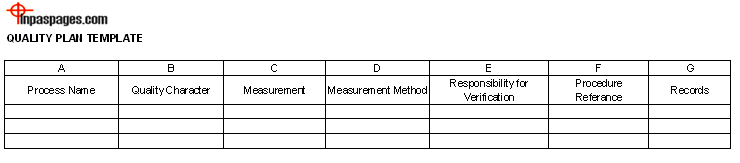

The quality plan should be clearly describing the following requirements:

- Name of the Process.

- Quality Characters.

- Measurements & Measurement Method.

- Responsibility for verification.

- Procedure reference.

- Record reference / document number / unique code reference.

See Picture:

Outputs from planning of product realization

All the results / outputs of product realization and its planning should be recorded in the quality plan for each organizational process. The organization make quality plan for business proceed or key process of organization, such as quality plan for product, and raw materials etc. A quality plan should be clear described the general requirements that are minimum requirements for the quality plan.

Department manager handles all records of planning for product realization. Actually, planning of product realization is important task of QMS. Hence the quality planning is important for identify requirements and implement product quality.