Planning of machinery maintenance

Planning of machinery maintenance is identify problems by evaluate all machinery to determine priority & criticality of the maintenance.

Planning of machinery maintenance is conduct for determines, provides and maintain machinery needs to achieve conformity to infrastructure management requirements. All the process machinery & supporting tools and its test are provided to complete the required standard for the maintenance, A periodic maintenance plan is order to ensure the machinery maintenance & operations of all machinery, services, Cleaning lubrication inspection tightening should conduct and replacement process are considered for the planning of machinery maintenance.

Identification of machinery

Identification machinery is very important to mange all the machinery for production & maintenance peoples to perform task, each machine should identified and proper tagged to easier for identify, in the machinery tagging machine name, machinery code, capacity, division and unit name to transfer, move, replace, repair any task will be easy if the proper identified and same should be recorded in the machinery list.

Machinery Assessment

Machinery used in manufacturing activities should be well identified and classified for the planning, each machinery should be planned for the maintenance are conduct on base of it evaluations, there are some basic evaluation of all machinery are classified to easier for the assessment here as below given machinery evaluation / machinery assessment to identify for the priority by identify critically of the machine:

High:

- Critical

- High Quality Driver

- High use

Medium:

- Less Critical

- Backup Available

- Reliable

Low:

- Low downtime

- Low Impact to process

- Easily Replaceable

Planning

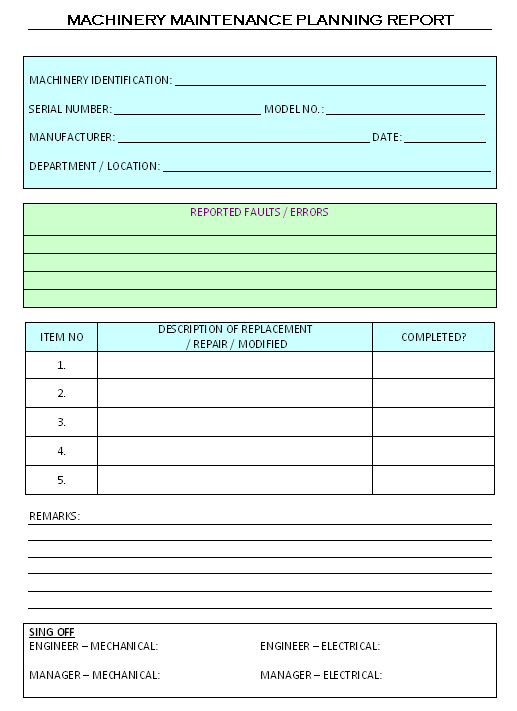

Proper plans helps to machinery maintenance techniques and efficiently and improvement. Planning functions are used the machinery standards to set up properly by manage its machinery planning in plan manner. Planning of the machinery maintenance are conduct and scheduled monthly / half yearly or annual maintenance as per machinery setup in the plant, planning team are conducting the schedules to drawn up of maintenance plan to effective implementation. Requirements of the purchasing of spare parts, tools and other materials are pre defined as per schedules for the maintenance. Proper planning improves machinery efficiency and as per planning records is kept machinery preventive actions. See below picture of machinery maintenance planning report:

Planning of the machinery maintenance are conducted on maintenance departments joint operation – mechanical maintenance and electrical maintenance are arrange meeting to planning of maintenance to consider all the factors which can disturb maintenance schedule. Some basic requirements of the machinery maintenance planning are conduct:

- Machinery Identification / Previous records

- Machinery Categories / Criticality / Priority

- Cleaning lubrication inspection tightening / preventive Maintenance records

- Machine substitute / availability – production Schedules & volume

Why machine maintenance planning is important?

Preventive maintenance is part of machinery maintenance planning, incase drop schedule for preventive maintenance for at least one month so we can catch up some potential results in production department there some issues are raised like machinery break downs unexpectedly increased, process cycle time will be dramatically increase, rejection percentage in the production are dramatically increase in percentage you can measure as usual.

Requirements of planning for machinery maintenance

Availability of machinery In the manufacturing unit having a busy due to schedule that possible about machinery availability is less than 96% or up, whenever planning for machinery maintenance arranged that material planning peoples’ support is much important to take the time for the machinery free or grant the sufficient time to perform maintenance task.

Unexpectedly breakdown in machinery is one of the important reason for the preplanned maintenance increase efficiency of the machine and possible to reduce percentage of the suddenly breakdown happen without warning. Motive of the planning is also to reduction in the unexpectedly breakdown in production.

Dependency system of processes is making complication for the maintenance in case suddenly break down occurred. In the manufacturing units are depends the process in the manufacturing system are dependent upon each others, in case any machine is down during the process that others are also wait for the material until machine are not producing / processing its task, means production can be down during for time, there are also impacts on the reporting indicate the failure of production unit that machine available time or up time is decrease that is also important for manufacturing unit.

———————————————————————-

DOWNLOAD MACHINERY MAINTENANCE PLANNING REPORT IN EXCEL SHEET

————————————————————————

RELATED TOPICS: