OSHA Plant audit and implementation – Safety Management

OSHA plant audit process helps to identify environment and safety concern requirements and implementation in line with standards system.

Overview

OSHA plant audit: In the manufacturing and engineering units are dealing with heavy equipment, machinery and materials moving during the various processes as part of production. The processes are used hazardous chemicals and materials which is red categorized materials can harm human body and environment. So It’s important for management to take care during various operations to reduce use of hazardous materials in processes. Use substitute materials or processes to provides safe working environment to employee. Its top management responsibility to understand OSHA requirements, to eliminate possibilities of risks and supporting factors, minimize use of hazardous materials by takes sufficient steps accordingly.

OSHA plant audit Planning & Implementation

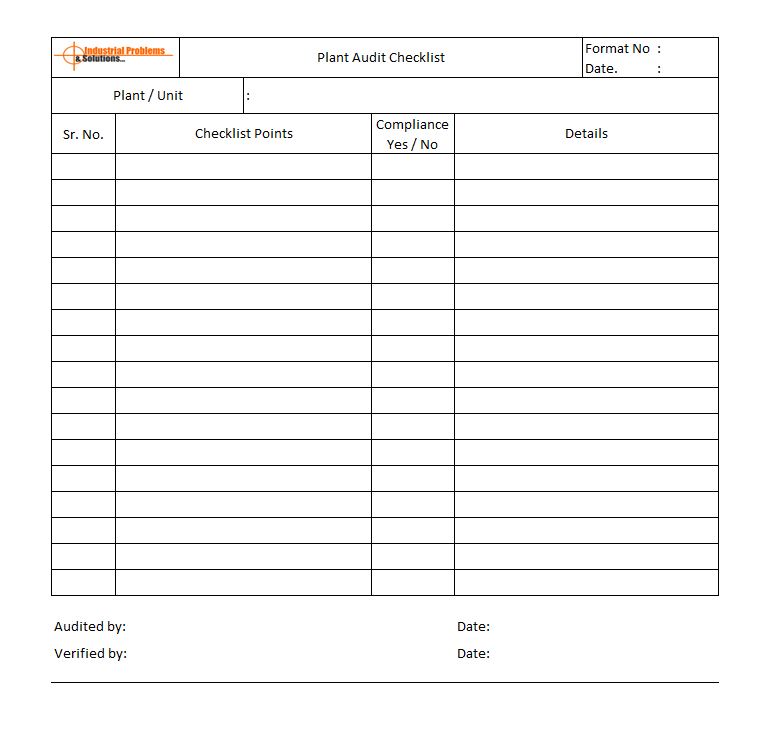

Plant audit is process where audit team conducts audit process as per standard requirements, technical and expected OSHA guidelines. The OSHA plant audit is conduct to identify requirements, condition and implementation of standard system to verify standard guidelines and clauses. Generally in the plant audit, concern manager and management representative prepared standard checklist to verify locations, processes and activities. To ensure the process safety and environment requirements. See picture below provided plant audit checklist as below:

Audit Document: OSHA plant audit checklist format

Plant audit checklist prepared by management representative and cross functional team jointly by identifying plant safety and environmental requirements. The team is concentrate on OSHA requirements to identify, manage materials, identification of hazardous materials, heavy equipment handling and controls. Verify the aware the peoples to maintain safety in workplaces.

See below some points that help to identification, maintain environment & safety as well:

- OSHA / Environment Health and safety policy prepare in local languages. It will help to employee can easily understand and follow.

- Environmental certificate has been obtained for the plant by certifying bodies. Environment certification is necessary as per factory acts and government rules. Certificate confirm noise level within the organization’s premises. Organization can verify the noise level to support of monitoring agency. An approved monitoring confirming the at air emissions from the plant. With waste water discharged to the main drainage line conforms to requirements. And also the certificate confirming that the land used by company is approved by authority after carrying out an environment impact assessment.

- Verify that environmental certificate obtained for plant from certifying bodies.

- Environment certification is necessary as per factory acts and government rules.

- Certificate confirm noise level within the organization’s premises. Organization can verify the noise level to support of monitoring agency.

- Verify that, an approved monitoring system confirmed the air emission from the plant?.

- Waste water discharged to the main drainage lining system, complied OSHA requirements?

- The land using by company is approved by authority?. Is there any certificate confirming?. The environment impact assessment is carrying out after the all confirmations and certification?

- Internal energy audit should carry out to check energy waste and recommendation have been implemented. First safety audit has been carried out and corrective actions should be implemented as and when required.

- All the plant should be maintained OSHA concern documents by filled by authority.

These are some general questions and needs to point solve out during the audit and as corrective actions to complied with OSHA requirements.

—————————————————————————————

Plant Audit checklist

—————————————————————————————