Operator Qualification Record

When any operator is leave the company or any new machine / plant is establish for manufacturing or any other concern purpose of the company that required operator of the machine or plant, for the knowledge of the operating machine / plant is required proper to operator for the each operations, company arrange the training to consider all the concern matter with the machine / plant, after training when the operator is able to handle independently, company is arranging operator qualification test that proof the effectiveness of the training and operator education / qualification / previous experience of the machine / plant.

For the operator qualification training & assignment are conduct on base of the operator education and qualification, when company feel the requirement of operator at any machine / plant, company appoint operator to consider of education, work experience on same machine or similar machine or plant, if the requirements are met with company requirements than operator is select for training of machine / plan operating.

Machine / plant operating training is given by qualified person who having all the aspect technical as well as operating and controlling knowledge to delivery maximum possible knowledge to trainees, hence operation qualification training effective conduct by plant in charge, plant manager or shift manager to support with trainer.

Operator qualification are conduct on routine shift and time at place where for operator is selected for operation on running batch / lot with some tagging of samples or any possible tag to easy for identification of material passed by under observation operator, in case the material is found satisfactory that material tags will remove and running tag are replace as usual proceeding.

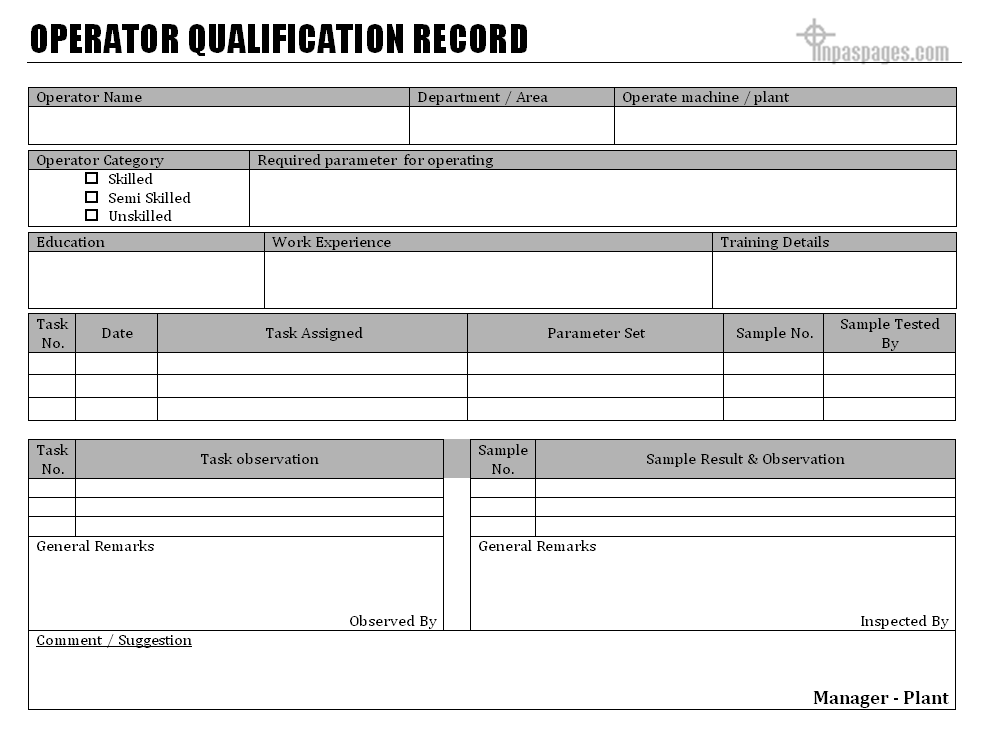

During the verify operator qualification required to maintain record of the each activities, operations, task and other details by operator qualification record, see picture below is evidence of the qualification records are maintain:

How to Operator Qualification conduct? & how maintain record?

Selected operator for qualification, observer team are deployed as required to easy for do it, operators are conducting works like a regularly performing, observer team are provided task to operator for the complete as required output as normal operator of the machine / plant. Operator is start work as instruction. Observer team is record information as below:

- Date & Provided Task

- Compare parameters set by operator of machine / plant with standard parameters.

- Take single sample from lot / batch & send to inspection team

- As per task samples are conducting on base of the lot / batch or dimension of the material.

- Observation team observe behavior of operator, how is performing and how much accurately performed.

- Same side sample inspection team is provided sample result with its observation on sample.

On base of the both the parties views, plant manager place its own view and decided for the operator is able to work at plant / on machine independently or needs further training, in case its performed good that operator will perform in routine work as others are.

EXAMPLES, SAMPLES & FORMATS

OPERATOR QUALIFICATION RECORD IN WORD DOCUMENT DOWNLOAD FREE

OPERATOR QUALIFICATION RECORD IN PDF FORMAT DOWNLOAD FREE

OPERATOR QUALIFICATION RECORD TEMPLATES DOWNLOAD

OPERATOR QUALIFICATION RECORD IN JPEG, PNG FORMAT DOWNLOAD

You would also like to read: