Material Requirements planning

The material requirements planning process for identifying materials for production, controlling the purchasing process to ensure that purchased product conforms to requirements.

Material requirements planning is the process that identify the product requirements through material requirements slips for planning department & as per requirements of the customers, pending order list are sources of the material requirements identification, material requirements planning should be accurate to arrangement of the planning are possible to manage. And also material requirements planning provides guidelines and procedures to controlling the purchasing process, activities in the manufacturing unit, to ensure product which is purchasing should conforms to requirements of the production, controlling on the purchasing system is the material producer on the demands of the production and against the jobs are established.

Material requirements planning are conducting by planning to cooperation of the material (Raw material) purchasing department to plan the material purchasing and controlling over the situation of the schedules, deliveries of product and undelivered material status. The management of the material requirements in the production to timely delivers material to customer. Purchasing staff is responsible for the maintain records of each material indents from planning, and the planning team is responsible to provide the documents of the requirements and schedules of the product required on date with schedule to production date, material insert date in the production and same the procurements are arrange.

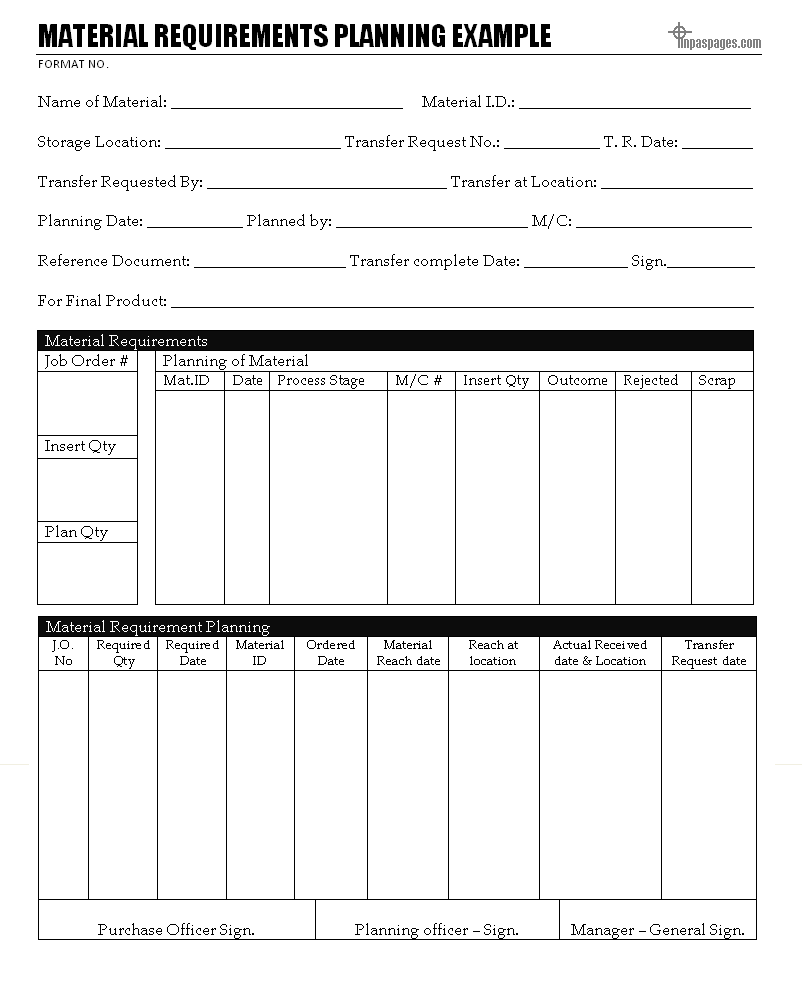

Planning department is provided information to purchasing department to communicate with suppliers for the provided the material on before the material required in the production, hence planning also confirm the material should not excess the amount of the requirements (Material purchasing are depends on the quantity tolerances), see picture below for the material requirements planning form which is provided by planning department to purchase department for the managing product timely:

Planning department is responsible to managing the product requirements to communicate with purchase department, planning of the job orders and expected delivery by customers based the system is implemented to compliance the material on time frame, the material requirements in the production is manage by planning to considered material and its available stock, in case of the material is not available with storage that immediate procurement are conducted to interact with procurement department and expecting the material requirements according the job orders. For the managing the material and specifications of the material are consider to reviewed all the jobs are established by marketing division, planning is bifurcate each orders and against required material are mange separately to identification of the requirements for procurement and same for the planning the material in the manufacturing processes, machinery and deployment of the equipment.

As above given format for the material requirements planning provided by planning to procurement department and general manager for the approvals, on approvals further actions are taken for the procurement and further planning of material. There two major part one is material requirements where all the job order or single job order is insert and measuring quantities are mentioned to inserting the material and against the planning for the material requirements are conducted to considering each job order, availability of materials and requirements of procurement.

————————————————————————-

Download format in Word Document | Excel Sheet | PDF Format

Download Material Requirements Planning example

————————————————————————-