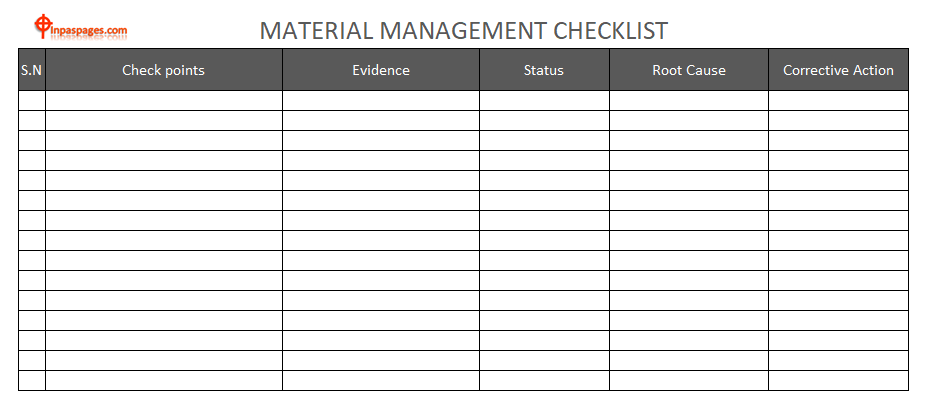

A material management checklist is document, may use to ensure the material planning, organizing and controlling activities are functioning accurately. It may focus on the material planing and execution capabilities. It may also contains the verification for the requirements for manufacturing.

What can be include in checklist?

- Is there material are identify Hazardous and non hazardous?

- Hazardous and non hazardous material storage are separate?

- Are the chemicals / oils / hazardous material store in a lock and key facility? Is there locking system is in controls of the authorize persons? Is there “key control system” is apply?

- Whether the stock is maintain properly? Is there issue material locations, receiver and all require details are maintain? Inventory’s each transitions are maintain properly?

- Whether all the chemical / Hazardous material’ Chemical properties are identify? Is there Material safety data sheet is available with department? And same are deploy at storage room?

- Is there procedures of the Chemical / hazardous material handing and storage? All the procedures are verify and control? Peoples are follow procedures? Is there specifically chemical accidents procedures are prepare? And in routine?

- Whether Safety equipment – hand gloves, Gum boot, Safety Shoes, gas mask, Glasses etc… Are provide for the handing and storage of chemicals / hazardous material? Peoples are wearing it?

- Is there nearest of chemical storage area safety shower is provide? Check where eye washer, body washer etc.. Working properly? Water supply force and should be clean is there?

- Is there any labels, signboards, arrows etc.. Sign brands are provision for the hazards chemicals?

- Are there any special vessels, containers for the collecting, transfer, moving, checking purpose the chemical residuals?

- At main Gate of storage area, arrow, and signboard are given to indicate the storage?

- Is there Re-order Level is maintain? What is the calculation for reorder level?