Manufacturing progress documentation

Manufacturing progress documentation is established to recording manufacturing processes progress to determine action plan for improvements appropriately.

Manufacturing progress documentation is established, maintained and updated to recording manufacturing progress to collecting information from manufacturing processes, records and daily sheets which are conducted in manufacturing various departments, all the collection are managed in the progress reports to proper conduct proper documentation, on collected database management is managing analysis to put marks on elements / subjects which in progress or not on control are conducted for proper implementation of action plan prepared based on progress documents. Management is analysis conducted data from production / manufacturing units to determine action plan for improvement target lines of each elements or key objective. There are also important to department wise each key objective are monitoring and in case any identify out of controls that management taken necessary action by improvement action plan for eliminate possibilities of managing all key objectives to proper controls and those controls deployed and analysis on control measures to impacts on other departments.

The purpose of manufacturing progress documentation is collecting information of manufacturing figures from various department and managing separate documents to identify key objective records for organize reporting in single format to easier for analysis of information collected. Analysis are conduced on information for understand status key objectives of company and its current status, management is compare level of each key objective to determine proper actions in case any key objective is not keeps its trends which can making loss of company, hence each key objective are controlled on level of department by monitoring to identify causes of losses.

Collection of information from various department are collected and analysis information of only which are indicates the company concern and its growth or losses, the information of elements which is not much important or not affecting company growth are not considered, the improvement steps are also conducted accordingly. Management determine which key objectives are important for company which impacting on the manufacturing costs, product quality and company reputations are conducted for monitoring and action plans are prepared and implemented accordingly. The information flows are managing at each level of the management i.e. department to management levels are collecting information identification, shorting and analysis.

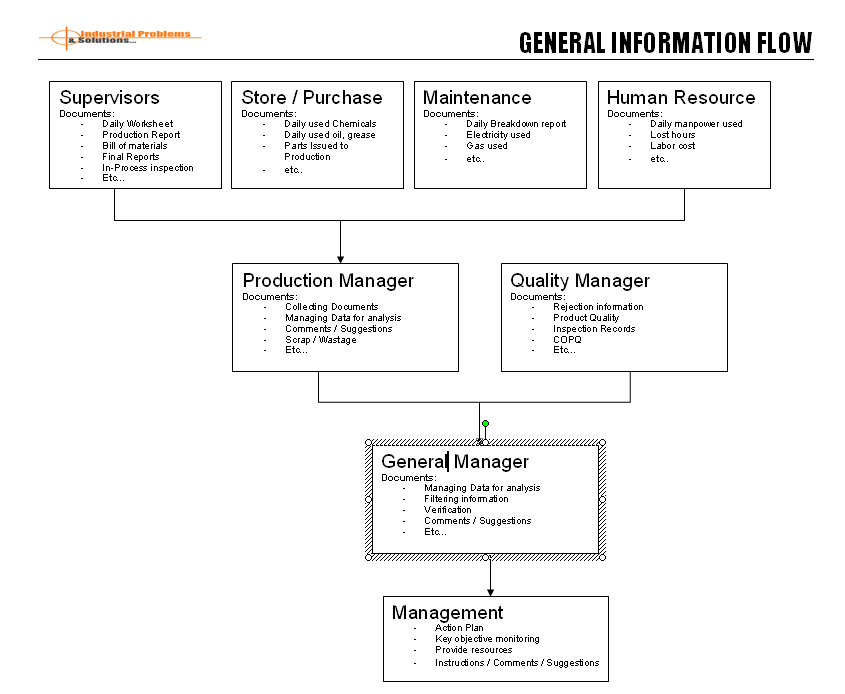

In the company collecting information, filtering and send to next stage is general flow which all the stages or the information flow should be accurately works and passed information on time. The information flows of the collection of information and its concern responsibility are assigned accordingly. Management is managing flow of information and assigned duties of jobs for the proper manage the records and information flow in the level wise to maintain system in the company. Assignment of job duties and responsible are recorded by the peoples as per management tasks, its assignments and flow. See picture below is general flow of information; the picture is in format given as reference of how company maintaining information flow, below picture can be fit the example with small scale / middle scale company and here we given example for education purpose:

General information flow for the conducting information from the manufacturing process fro manufacturing progress documentations are conducted from supervisor which are conducting bottom level but very prime information which conducted form daily worksheet which are maintained with the all details concern jobs are running in manufacturing processes, production report where all the details of the machine’s production – input to output of the production are covered, bill of materials used in the productions, in-process inspection and its sampling information and its result that important for the batch wise quality checking and final report which is prepared at the end of the day to collecting all information i.e. conclusion of full day production activity, supervisor is responsible for collecting those information and pass on to production manager. Store and purchasing department is equal responsibility to provides information of the daily used of chemicals in production department, daily used of oil, parts and other materials to production, hence maintenance department will be responsible for provide information of all machinery and equipment daily breakdowns, electricity used and gas used for machinery and equipment or plant. Human resources department having the responsible to provide daily manpower used in the production with lost of hours to calculate as per labor availability, and its concern cost of each labor to easier for analysis cost of product or manufacturing overall. Production manager is responsible to collect all information form various department, managing all data for analysis, attached and analysis of scrape and other wastage reporting to general management, quality manger is also equal responsible for the provide information of rejection information, product quality and inspection records with cost of poor quality (COPQ) to easier for analysis. Achieve all information from production manager and quality manager, general manager is analysis all information and filtering information as requirements for manufacturing process documentation, verification of information is also important at places to right information can pass to management. Same the management is collect information from general manager and analysis information, analysis key objectives and monitoring and prepared action plan and its required resources provide to manufacturing to improve the productivity.

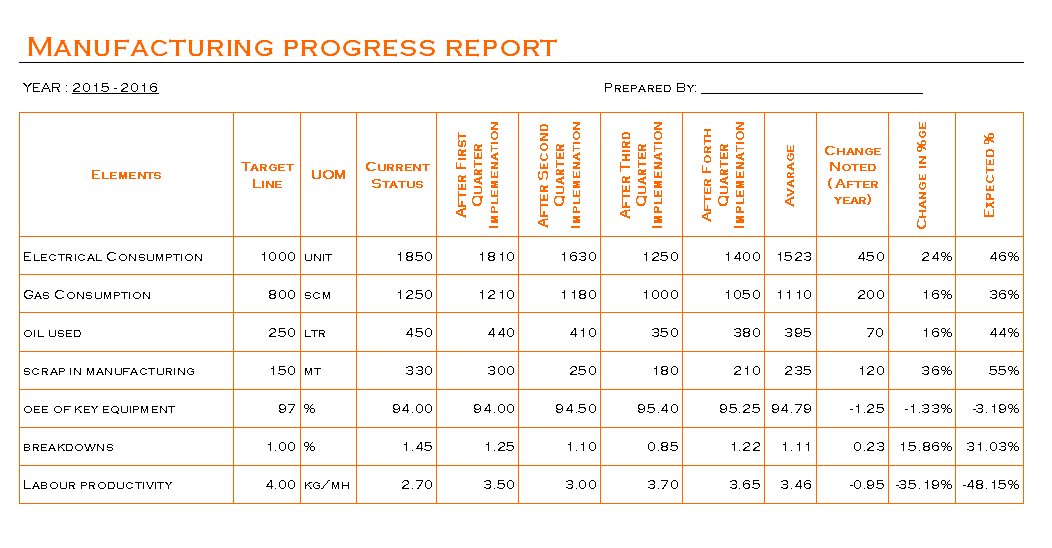

On the collection of the information, general manager is preparing the document which is called manufacturing progress report which is submitted to top manager on the completion of the year or quarterly basis, the document is one of the main document which is indicating the progress of the manufacturing unit there all the information progress are described, the information are collected from production manager and quality peoples are merged and filtered as necessary information are used for manufacturing progress report. The report is key document for the management which quarterly information are used and its progress of key objectives are indicated, the key objective progress are indicates the company growth or particular objective achievement during the quarter period. In the key objectives are general used material in manufacturing processes and its improvement like a electricity consumption are reduction targeted if by manager that on after quarter what is the progress of the actions are taken during the quarter and its record information are indicate manufacturing progress report. And some materials and chemicals are counted in categories in hazardous that should be needs to reduce as per government and environmental standard requirements, hence the reduction of the oils, chemicals, hazardous gas levels of use and its reduction are recorded. General manger is submitted manufacturing process report to management for improvement of the manufacturing unit, see picture below given as example format for the manufacturing progress report for education purpose:

General Manager is also suggesting and comment on the information for improvement with action plan are prepared for the reduction of the hazardous materials in production, hence other key objective improvement action plan is consider along with in report as individual submitted to management. Management considers all the points to concern manufacturing progress report and some points for the improvement are as below:

Management is concentrate on basic requirements of the production and concern department to improvement, some points that are manufacturing process capability, reduction of wastage and scrap which are generated from the various processes and machinery, setup time of the machinery and equipment, consumption of the tools and improving overall equipment effectiveness of key machinery are major point which are directly impacting on production field. There are also important to minimize cycle time of the process with possible download time of machinery and equipment are also on priority for management, emergency reduction, oil, gas, chemicals reductions and nos. of accident / incident reduction are major for safety point of view. Management is conducting all the major factors and point and prepare action plan for improvement in production processes.

——————————————————————-

Download format in word document | Excel Sheet | PDF format

——————————————————————-