Managing Procurement operations

Procurement management is process to communicate & procure materials to console deal with vendors for compliance end up requirements.

Procurement involves the purchasing products form vendors for use in operations with comfort values & delivery to comply all the requirements of the company’s internal users, requirements of the various departments of company, this functions are deal with vendors / suppliers by communicate on some basic factors that dealing are completed with both side satisfaction.

Procurement / purchased products having categories that compliance the needs of internal departmental requirements are:

- Consumable goods – Consumable goods purchasing on demands of maintenance, accounts, etc., that purchase product is finished after used or used at the supporting of the manufacturing process. Consumable goods can be components, stationary, tools & other materials which are used as support for manufacturing process activities.

- Raw material goods – Raw material goods is mother material by finish product can be manufactured, on base of the raw materials finish product quality & product are produced that raw material purchasing needs more concentrate during procurement.

On procurement / purchasing management proper controls required to ensure the material conform are purchasing & consuming are proper compliance & satisfactions are achieved to end users, controls over the procurement is possible by verification of the purchasing products.

Procuring / purchasing product information

If the vendor is not certified by quality standards that customers can perform the internal quality system audit at supplier end to ensure the product quality and system requirements, customer can carry out their own assessment according to quality management system support, supplier approvals are decided on base of the improvements and compliance of the system requirements. Procuring products should produced in quality system environment which are needs to conducts all the clauses requirements that assurance of quality products, according to Technical specification – 16949 recommended for the quality system improvement in supplier chain that means each customers should be responsible to upgrade its suppliers and develop proper quality system requirements in suppliers’ end.

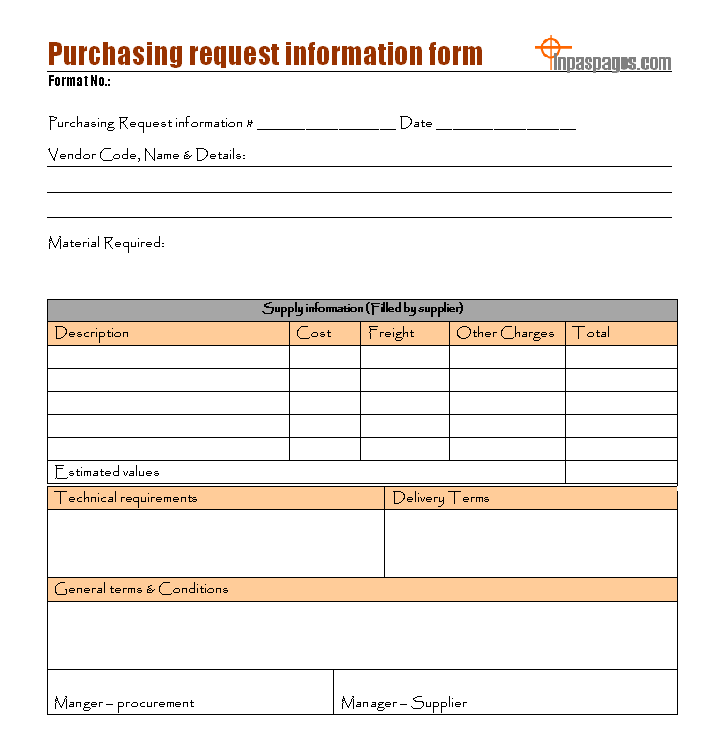

All the procurement are conducted in standard formats which are mentioned with product description, quantity, supplier references, product cost, supplementary information, delivery, technical terms and special process requirements that information are need to conducted on primary base of the inquiry levels, these are depends on the customer requirements levels and purchased information collected from suppliers which called quotations, by compare quotes form suppliers, customer is raised the procurement indent to suppliers with proper information. Here as below procurement / purchasing request information form given for reference:

In the purchasing request information should be covered, completing the processing all requested information, all the information will be collected by procurement department to processing further actions.

Procurement indent

On base of the supplier product information (Quote), customer is compare all incoming quotation information to finalized the procurement deal with any supplier whose having a comfort conditions to makes possible procurement deal, customers are raised the procurement indent to supplier by comparing the internal requirements & schedules as the purchase order.

Verification of purchasing product

All the incoming materials should be produced by international standards, if the materials is manufactured by certified company that material quality assurances are reliable & incoming materials controls are defined the same, incoming materials are not 100% inspected if the reliable sources, hence the non certified company is need to fully controlled and proper inspection required to verification process conducted or there are also option to verify or inspect the materials at supplier’s end by visit qualified personnel to inspect the material at suppliers’ premises, the criteria for inspection should be clear prior to the visit & all the functions are conducted by quality peoples. Overall procurement verification is depend on the products and sizes.

Proper manage of procurement operation is very important for view of finance, internal requirements & priority of the company’s projects that managing all the procurement and operations are serious task to compliance each requirements in time frame.

————————————————————————————–

DOWNLOAD FORM, FORMAT IN WORD | EXCEL | PDF

DOWNLOAD PURCHASING REQUEST INFORMATION FORM

————————————————————————————–