How to manage zero tolerance for unsafe acts

Zero tolerance for unsafe acts is process help to determine precaution, controls and provide assurance to feel safe working environment.

Zero tolerance for unsafe acts is process or procedure that deployed in the system to provide safe work environment to all employees working at various locations and workplaces with heavy machinery and equipment where activities and handling of materials cause incident or injury during working. The system supporting to understand unsafe areas, locations, activities, machinery, equipment concern activities and materials movement are general for identification of the unsafe acts, during inspecting all the areas that needs to manage and identification of unsafe conditions. The company should be establish zero tolerance for unsafe act as object that should be company level objective will covered and scoped all areas and location of the workplaces, the system provide all employees with a safe environment when the zero tolerance for unsafe acts is manage as objective. Zero tolerance for unsafe acts are managed as objective, the management is defined as objective, establish as objective, maintained and update the records of the zero tolerance for unsafe acts as company level objective, this objective concern records, information, collection of data and analysis for improvement are managed by management, where management representative is responsible for collection of records from various department, and departmental head is responsible for collecting records from its department and submitting to management representative.

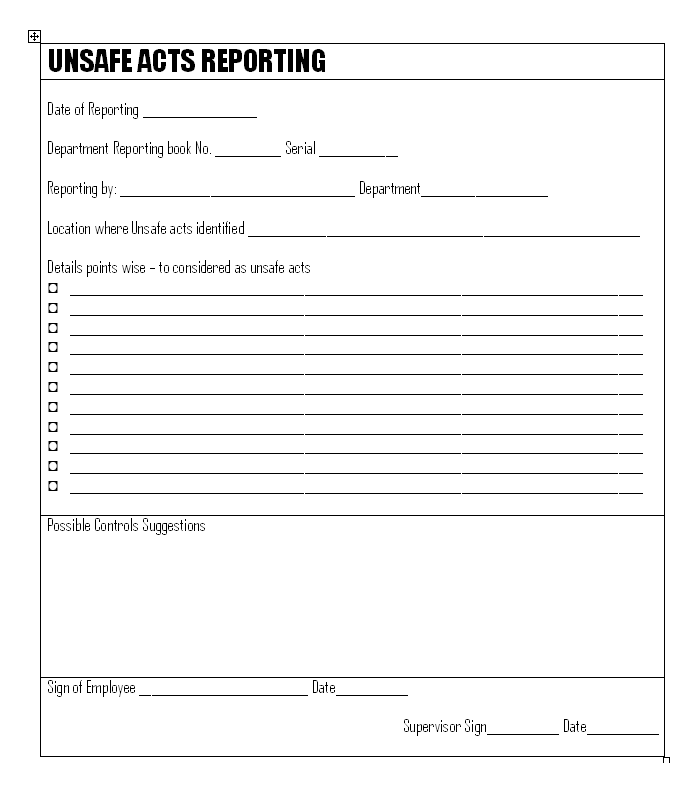

The zero tolerance for unsafe acts as objective consideration for safety point of views are managed in each and every decision of management, when development of any new product or process, improvement of current processes and new machinery, equipment or any devices are purchasing and installation at workplaces. Safety and it concern requirements concern responsibility is equal for all employees works in company that individual responsibility are assigned for particular tasks are excesses, the responsibility to wear required personal protective equipment and strictly follows work instructions, safety precautions and guidelines for safety points, and also needs to aware the peoples does not use any activities that raise potential hazards in workplaces. Every employee working in workplaces are responsible for identify hazards at its works and reporting to their supervisors, and involve minimizing risk levels or eliminating possibilities of hazards at particular tasks or activities / processes attached with it. When any employee identify any potential hazards at its workplace, at machinery, equipment or devices, or in the processes that employee should immediate report to their supervisors for the unsafe acts, and the reporting should be manage and needs to immediate determine action for safety. See picture below given as example format of unsafe acts reporting used by employee for reporting:

On base of the unsafe acts reporting, supervisors are verify concern processes to identify and short out potential hazards, and discuss with production manager or concern higher authority for conducting corrective actions / preventive actions against potential hazards are identified. But the zero tolerance for unsafe acts are conducting mostly for the managing all employee aware for the wearing personal protective equipment, and acts during the workplaces to minimize risk levels and managing its tasks safer that directly or indirectly not raise any hazards that any other employee affects or any incident occurred due to unsafe acts.

—————————————————————————

Download format in word document | Excel Sheet | PDF format

Unsafe acts reporting

—————————————————————————