Fixing and re-assemble process in engineering unit helps to manage identified defects and its solution to provide quality materials to customers.

Overview

The establishment needs to process of fixing and re-assemble in engineering unit. To identification of defects and its solutions to fixing the errors. The impacting on the all the running parts manufacturing and assembling in engineering unit. The process is maintain for improvement of quality and parts that expect by customers as per standards, technical requirements and specific requirements of customers.

The fixing errors in parts / model that is product is important for maintaining quality standards and end application requirements. The quality engineering are responsible for maintaining and implementation of the processes. To fixing and re-assemble for particular product having a issue identify during in-process or final inspection process.

General Procedure

The general procedures that help to determine actions on fixing and re-assemble in engineering unit:

- The product / parts / material having the non-conforming identify during the manufacturing, assembling or quality inspection stages i.e. processes of various operations shell be handle through controlling by proper documentations and guidelines. To manage tasks and define control over non-conforming materials / parts / product.

- The processes results of non-confirming materials / parts / product. That manage as requirements, the results should be either disposition or apply the process of fixing and re-assemble as standard product guidelines and standard system for end application requirements.

- The important tasks of the materials / part / product. Which is under the fixing and re-assemble that should be maintain separately. The reject materials for the particular defects should be clearly identify. The components that are to be fixed and reassemble. The documentation, tagging & segregation processes should be maintain at each stage of manufacturing and assembly lines.

- The materials / part / product completion of fixing and re-assemble process needs to quality tasks. That all the materials should be re-inspect as company quality guidelines. There should be full materials inspection of sampling plan with acceptance of rejection criteria as quality standards with defects identify and fix.

Documentation

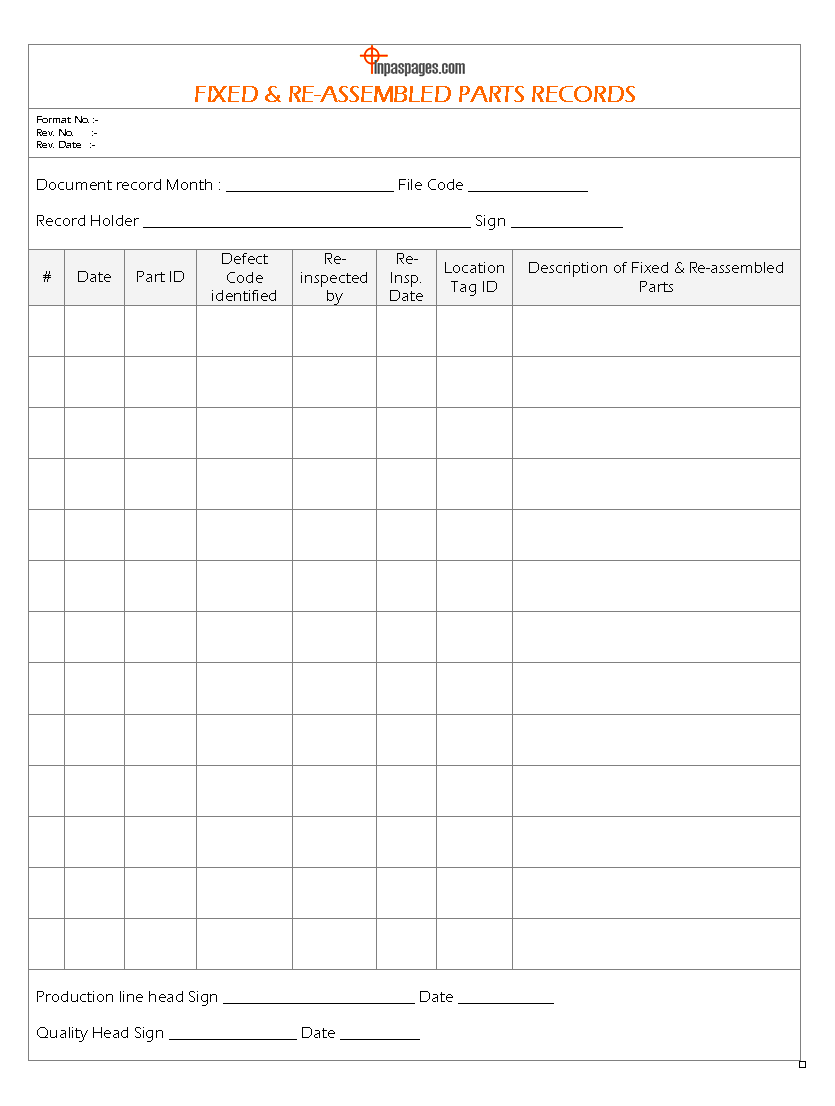

The quality team is conducting parts that having issues and re-assemble by assembly lines. Its re-inspection and its records are manage accordingly. See picture below given as example format of records that use to managing each fix & re-assemble product parts records. Which manage by assembly lines i.e. production team.

The production supervisors are recording that information, and register each part having issue, fix and re-assemble with re-inspection process had conduct. Below picture given for education purpose:

About Fix & Re-assemble parts record

The fixing and reassemble process should be review and approve as per standard system and by customers as parts / materials is being re-assemble. The materials / parts should be properly record all information to easier for concern engineer to identify re-assemble product and manage its separately. As well costing team should be also conduct the tasks as its financial requirements. That each product should be proper tag to easier for all concern peoples. The documentation for the fix & re-assemble parts are manage as per documentation system and its records are complete on re-inspection process is complete.

————————————————————————-

Download format in word document | Excel Sheet | PDF format

Fixed & Re-assembled parts records

————————————————————————-