Machinery utilization analysis

Machinery utilization analysis is established to identify individual machine utilization, breakdowns & unused time for machine management improvement.

Machinery utilization analysis for each machinery installed in the workplaces, production lines are conducted to identify individual machine utilization of machinery, breakdown during the month as well as calculating annual and unused / empty time of machinery information are collected, analysis for the minimize breakdowns and unused time of machinery and improvement in utilization of machine through proper machine management by analysis. Machine utilization analysis is important part of the manufacturing unit that each machine utilization improvement that is overall equipment efficiency or productivity improvement can enhance production, reduce time frame or reduction in time to manufacturing product and cutting in cost that overall its beneficial task for manufacturing processes to improvement in the machinery utilization.

Machinery utilization analysis is conducted on base on collected information from various production lines from various departments for same machinery; generally machinery utilization analysis is conducted to managing installed all machinery in production lines to overall equipment efficiency improvement, the analysis is conducted to collection of monthly and annual data which is collected during the month by concern supervisors, all the data are submit to general manager for further analysis, general manager are input all information in table format and identify daily / monthly utilization percentage to easier for analysis. Percentage of the utilization are identified on base of available time for day and night for full month against percentage of works are conducted that raised utilization percentage for individual machine. (See topic: How to identify utilization / overall equipment efficiency). Those information are managed for machinery utilization analysis for the annual report, in the report each information are organized where utilization percentage, same as breakdown percentage and other time percentage which is unused or empty time percentage of machinery.

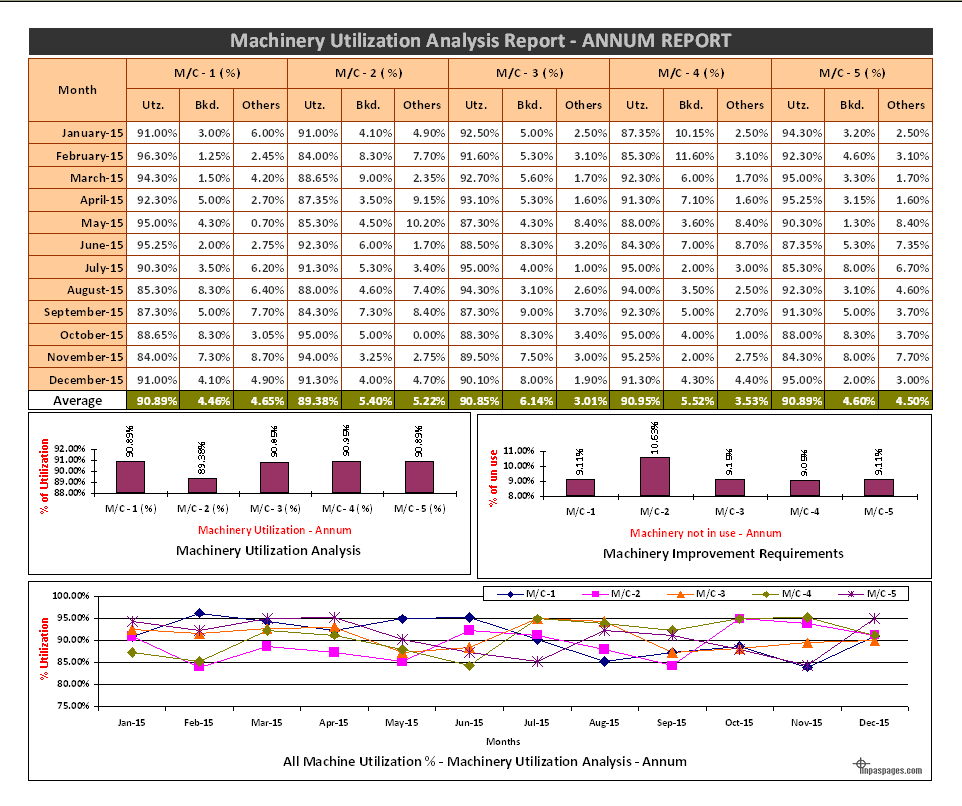

Machinery utilization analysis documentation and records are handled by general manager, and responsible for conducting information from various departments and processes of machinery production, time used and other concern information for analysis. Concern supervisors are responsible for providing that information to respective machinery and concern details. For the managing analysis records and base format for analysis is machinery utilization analysis report, see picture below given as example format for education purpose:

Machinery utilization analysis report is covered utilization percentage of the machinery, breakdown percentage and other information to analysis individual machinery records to identify requirements of improvement of machinery to conducting analysis, the records are managed as per machinery wise to conduct improvement actions accordingly. On base of the analysis, management is determine action plan for improvement, which machinery is conducted for improvement are decided on base of priority setup, and same the records are maintained for further actions.

————————————————————————-

Download format in word document | Excel Sheet | PDF format

Machinery utilization analysis report

————————————————————————-

Related: