Machine cycle time audit conducted to ensure the machine had maintained its standard cycle time to producing materials and quality of product.

Why machine cycle time audit required?

- Analysis purpose

- Improvement of productivity

- Identify troubles ( hidden)

- Current condition of machine

- Planning of production

Each machine having its standard cycle time to producing materials for particular product and sizes, and the time which is conducted for producing materials, completion of cycle that is inputs to output time is cycle of product / size or lot as specifically considered or process owner defined by measure the time and lot requirements for particular product and its sizes.

The machine is frequently work in production lines hence needs to verify the timely for accuracy, quality of product for understand the cycle time conducted on after some time frame. Production peoples conduct the processes to under observation of production head to ensure the machine had maintained its standard cycle time. The purpose of machine cycle time audit is to ensure that the machine maintained it standard cycle time which is measured at on established / installed, or previously calibrated. This is the important tasks should be needs to conduct and verify the machine cycle time.

How machine cycle time audit conduct?

The standards system for machine cycle time audit and measurement are depends on machine type, production lines, machine requirements and manufacturing guidelines are important. The machine cycle time audit is conducted on base of the manufacturer manuals, measurements and figures are collected on time of installation and on after calibration reports are consideration required. For the audit needs some requirements:

- Quantity of product (Particular product / size / specification / grade etc.. )

- Load & unload time ( for measurements / to compare previous records of cycle time that is standards cycle time)

- Man hours ( concern manpower used in standards records and current used resources )

- Differences in quantity, quality and produced quantity.

- General observation and remarks

The machine cycle time audit can conduct by many ways; its all depends on machine and its product applications. But the motive is improvement of productivity of machine.

Frequency

Machine cycle time audit should be conducted each six month is recommended, the various / deviation in product sizes, tolerances can be maintained if properly audited and actions are conducted. The frequency can also need to define to communicate with machine manufacturer for auditing / checkpoints and standard cycle time.

Responsibility

Production manager is responsible for product guidelines and procedure for machine cycle time audit. Even also for assign duties to production supervisors to conduct audit at appropriate requirements. Hence product supervisors is responsible for conduct the audit tasks as per frequency define as provided manuals and procedures. The documentation for the machine cycle time audit is prepare by supervisors as per visited and audited the time. The same the reporting to production manager in written report for verification and reviews.

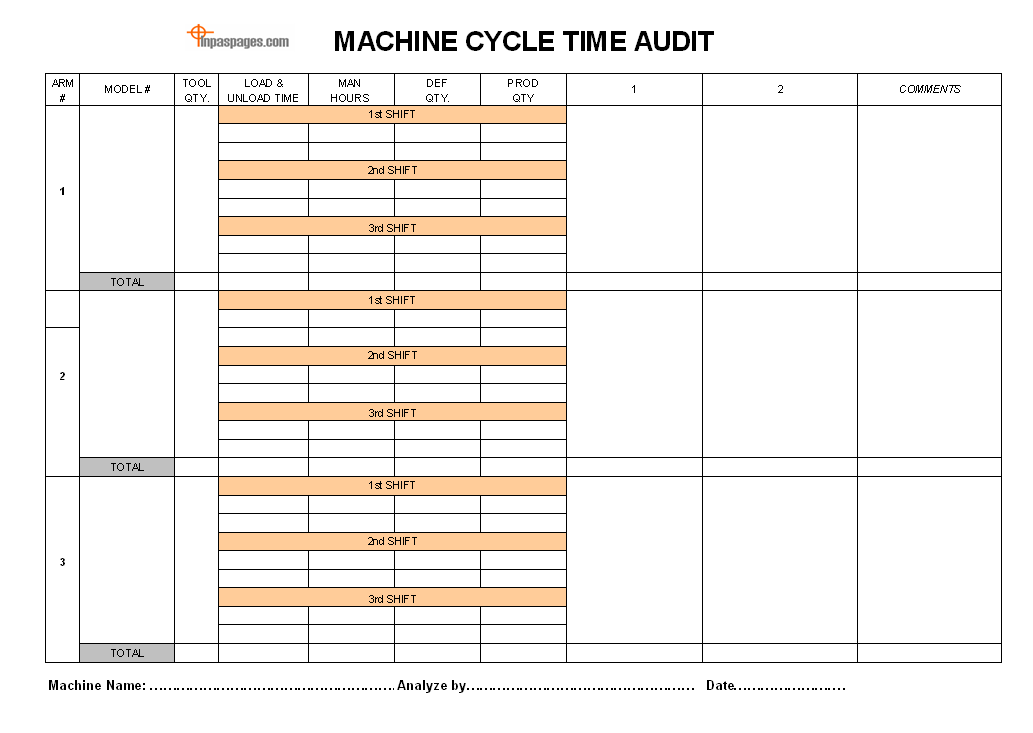

See picture below provided example format for education purpose:

The outputs form the cycle time audits are machine productivity improvement / efficiency, identification of critical parts. The planning team can refer the reports to understand the current condition of machine for planning of order received. And maintenance team can perform in case the maintenance requirements.

—————————————————————————

Download format in word document | Excel Sheet | PDF format

Machine cycle time audit

—————————————————————————