Kaizen review process is strategic evaluation of the entire activities of kaizen to ensure the continuous improvement at the all level of the organization. The process may use to improve stage wise improvement of each manufacturing process.

Introduction to kaizen review process

In the manufacturing processes and its supporting activities that engage to producing materials as per standards requirements. To considering quality requirements and as per customer technical requirements. During the manufacturing processes some basic requirements and its processes needs to frequently improvement. Even to maintain and enhancement in product quality. As well improve resources efficiency and overall productivity in manufacturing unit.

The management are conducting some improvement system that help to determine actions. Such as on resources, time management, process management & techniques that help to improve. Kaizen is one of the important system that currently business is adopting and improvement in product quality, managing activities for improvement and sustain standard system by effective implementation.

Kaizen for manufacturing processes

The kaizen is technique regular & effective for manufacturing unit. Hence the management implement in various stages of manufacturing processes. Even that whole organization manage in scope to improvement. The documentation of kaizen process is manage by collecting information of kaizen steps that conduct in units. The documents are help to manage its records & also helpful for establish proper analysis of kaizen records. To identify improvement of stages by reviews records of manufacturing processes & kaizen system.

Kaizen process is also concentrate on some important part of the manufacturing activities, processes that handling materials and movement. The kaizen re-work analysis due to some defects that occur are verify & identification of sources are manage and performance improvement. Through kaizen system are popular in the manufacturing industries.

Monitoring

The kaizen is also manage for some kind of experiment in the manufacturing processes. The system is manage through some kaizen ideas and concern management is monitoring and controls over processes to identify weakness in processes for improve manufacturing processes to each stage of process manage with full efficiency.

Verification & kaizen implementation

The kaizen documents reviews are not just documentation reviews that manage verification & its individual process of kaizen. To verification and kaizen implementation, kaizen subjects, kaizen ideas and its result areas that verify implement results. To ensure that the each process of kaizen and subject ideas are implement properly as cost expect during planning.

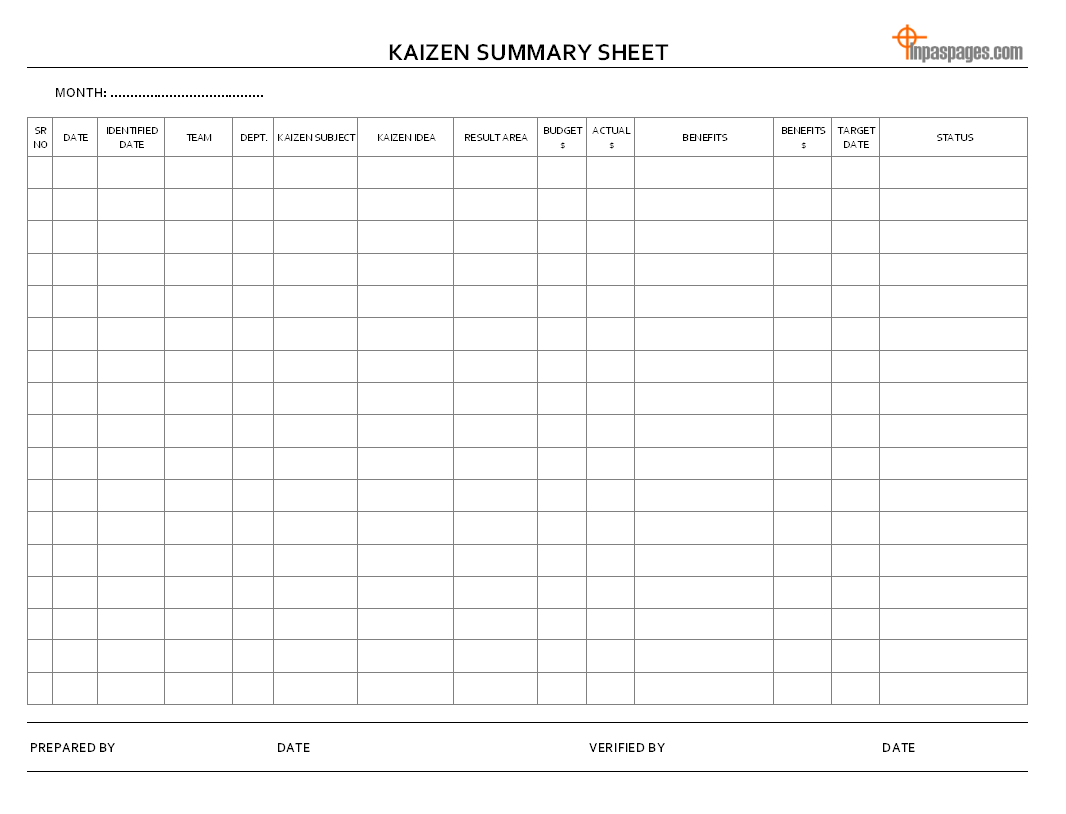

The documentation are maintain by kaizen management. See picture below given as example format that handle to managing records and reviews. Below picture given for education purpose:

Kaizen summary sheet

A kaizen summary sheet is format that use to recording information of each kaizen activities to manage for reviews. The documents as well kaizen processes to ensure the stages of kaizen is conduct properly. The kaizen ideas and its implements are deploy, result of areas are verify the status of kaizen. It may also verify the kaizen process cost are as per planning to match the benefits through kaizen processes as appropriate locations and processes. The documentation for the kaizen is manage as per standard documentation system.

————————————————————————-

Download format in word document | Excel Sheet | PDF format

Kaizen Summary Sheet

————————————————————————-