The inspection levels designates the relative amount of inspection. Normally sample guideline provide a technique to identifying the different levels of quality inspection and priority.

Overview to Inspection levels

In the manufacturing unit, engineering or any other unit that needs to implement quality inspection to identification of the product quality, standards requirements, and customer specific requirements to provide standards products. The quality inspection setup, implementation & deployment of quality procedures, guidelines & resources in applicable areas. But there is also important that each quality inspection process should be conduct as per schedule and requirements of customers.

The quality team is manage the quality inspection to understanding the appropriate attire and inspection level. The purpose of this sample guideline to provides a method for identifying the differences between quality inspection levels. The quality inspection levels identification process is manage as appropriate department and units. That all the concern employee are responsible to conduct and implementation.

How to ensure the requirements of inspection levels?

The quality team is responsible for understand the appropriate machinery, equipment, customer requirements and inspection processes are manage. The inspection level on the related machine are conducts accordingly. The quality engineers should be verify & manage its reporting and tagging on completion of the inspections levels. They also needs to ensuring the employee working on the machine / equipment are properly manage as quality inspection level requirements.

The concern team that is marketing and sales team should be conduct and determine customer requirements and conveying the intend use to the manufacturing unit. The whole process for the quality inspection levels are manage as stages are require as customer technical and concern requirements of end applications.

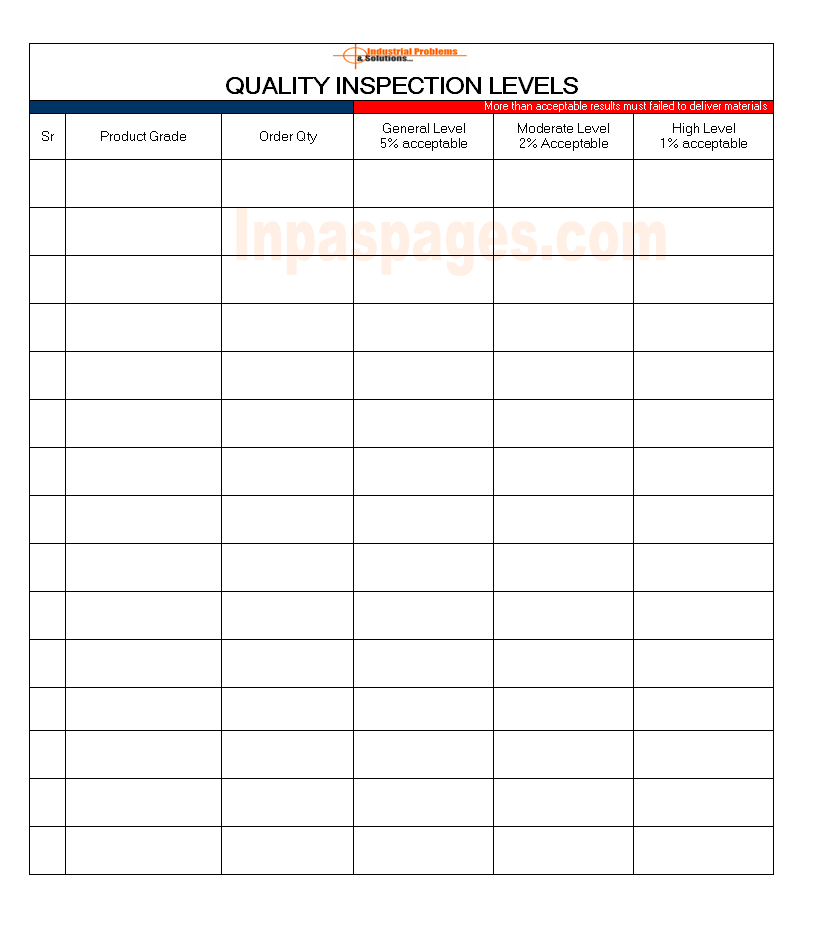

The documentation are manage for the recording information of quality inspection levels. The documentation describe the which materials, lots, product quality against how much percentage are acceptable. Over the level of acceptance can fail to deliver materials that all the rejection percentage are manage accordingly. The documentation manage for quality inspection levels format.

Quality inspection level template

See picture below given as example format for education purpose:

How to use quality inspection levels format?

Quality inspection levels format is use to recording information of quality requirements for particular product, and its acceptable levels to ensure the product quality. Hence the quality team is conduct according to quality inspection level are define by quality team. The quality inspection levels are identify as per product specifications requirements. Hence the identification of quality inspection levels and maintain the levels, conducting inspection process is part of regular tasks of quality team. The documentation process is manage and implementation are conduct as per quality documentation system.

—————————————————————————–

Download format in word document | Excel Sheet | PDF format

Quality inspection levels

—————————————————————————–