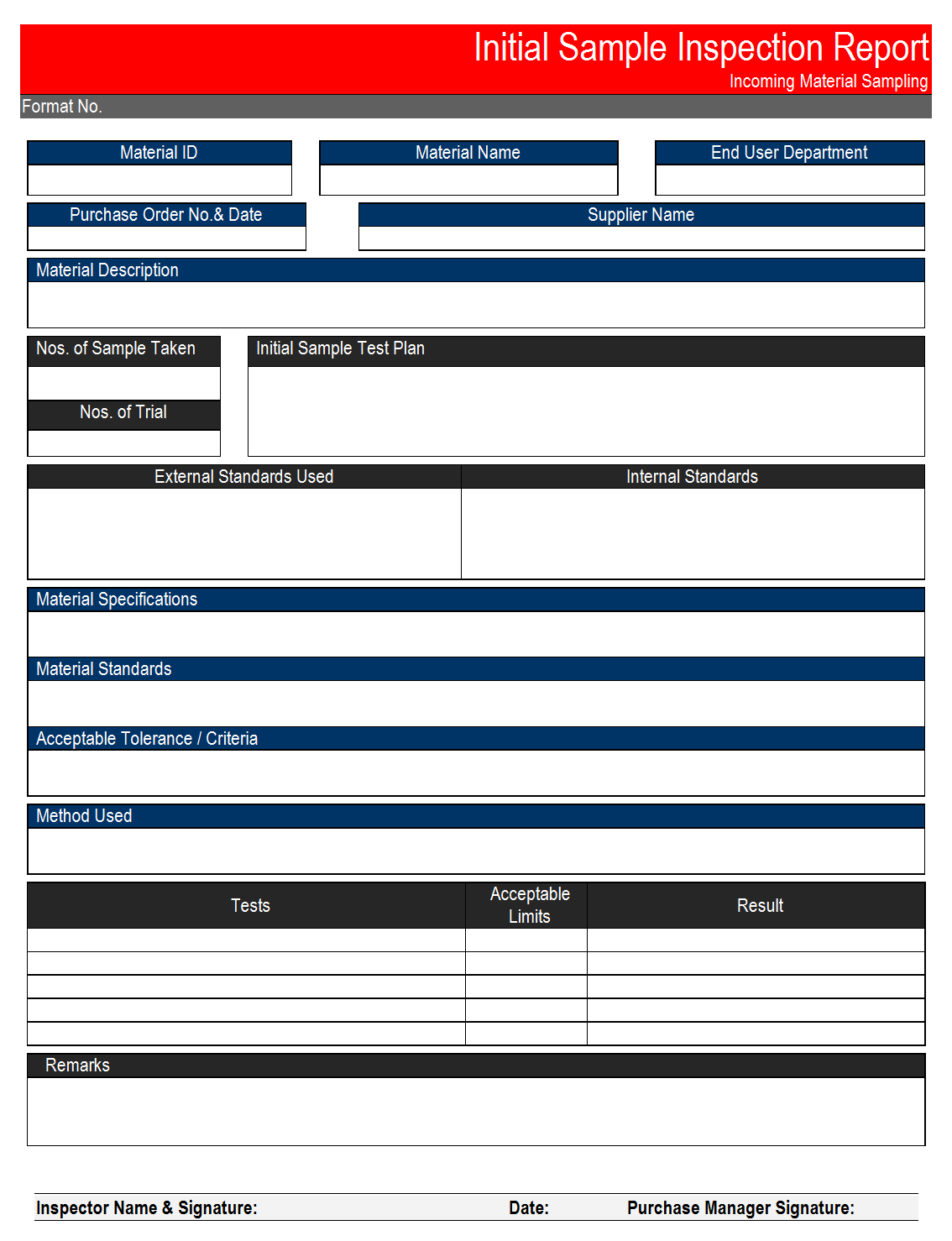

Initial Sample Inspection Report

- Material ID and Material name

- End user Department – Department that given the request for the material which samples testing is taken for inspection, this end user department’s requirements / application requirements are considering in this inspection.

- Purchase order Number & Date – Against the purchase order number and date is used.

- Supplier Name – Name of the supplier that supplied material’s sample are taken for the inspection.

- Material Description – Details of the information, description of the material are used for supporting information, specification, standards etc.. Information is very important for the inspecting the sample. Hence this information is primary or base information for the inspection.

- Numbers of Sample Take – randomly inspector takes the sample for the inspection to identify, inspection purpose.

- Numbers of trail – On the single sample, how many trail will be take for the inspection, details of trail will be indicate here after the numbers of trail entered.

- Initial sample test plan – basically when the samples are taken for the inspection, what type of test, which kinds of test, how many types of test required for the particular sample, what type of material used and on base of the testing acceptance will be required etc.. Prime information need to show here.

- External Standard / Internal Standard – All the external and internal standard information is very necessary for the inspection process, when the company are takes the sampling plan that all the concern international standard which through the material is constructed, inspected at supplier end that should be considered standards should be external ( international standards and its requirements complied ).

- Material Specification – Any kind of material has a specific value which is used for the inspection, checking to understand that all the standards are maintained in material.

- Material Standards – Material that made on base of the international standards as the chemical, physically or any other mechanical parameters that are consider the standards and its requirements, base construction of the material should be follows the standards and its requirements, which is identification of the material on base of the standards.

- Acceptable Tolerances – when any material are going to inspection, some variation, deviation acceptable as per application requirements, when the customer application and international standards are recommend some tolerances and is acceptances for the application end used that acceptable tolerances are considered as the basic pivot.

- Method used – Any kind of the inspection, sampling inspection or final inspection are work on base of the methods, on which methods are used for the inspecting material is need to indicate in here.

- Testing Results

– Tests – The entire required test as per sample’s specification, grades, and standards to find out fact result.

– Acceptable limits – What acceptable limits for the inspection results, if the acceptable tolerances limit match with the result that should approved.

– Results – all the facts finding are mentioned in this column

- Remarks

- Signoff – inspector

EXAMPLES, SAMPLES & FORMATS

INITIAL SAMPLE INSPECTION REPORT IN WORD DOCUMENT DOWNLOAD FREE

INITIAL SAMPLE INSPECTION REPORT IN PDF FORMAT DOWNLOAD FREE

INITIAL SAMPLE INSPECTION REPORT TEMPLATES DOWNLOAD

INITIAL SAMPLE INSPECTION REPORT IN JPEG, PNG FORMAT DOWNLOAD

You would also like to read:

- SITE INSPECTION REPORT

- VISUAL INSPECTION REPORT FORM

- STANDARD FINAL INSPECTION REPORT

- DIMENSIONAL INSPECTION REPORT

- QUALITY INSPECTION AND TEST PLAN

- MONTHLY INSPECTION RECORD SHEET

- DAILY MACHINE PRODUCTION REPORT

- TRIAL VALIDATION REPORT