How to effectively implement process control in organization

The implementation of process control in the production related activities to identify technical solutions, enhancement capability of measuring, inspection, methods and techniques to meet standard quality product.

Introduction

Organization generally deploys process control for manage manufacturing and assembling processes. The product can produce by systematic and according to standard procedure. Where all the technical aspects, standard requirements and process mapping are manage accordingly. When you are establish process control in manufacturing processes. Make sure that will be department wise or process wise?. In both case head of department will be responsible for monitoring of production activities.

Process inputs / outputs

Identification of primary process requirements are inputs and its outputs are verified to ensure the product quality and define control measures accordingly. The process reviews, acceptance criteria of all process inputs are needs to identify and manage in separate database to easier for manage control requirements. During the reviews of each process inputs, all the bill of materials, raw materials and supporting inputs should be properly reviewed and identified as acceptable level, hence the outputs of the process in line with inputs are indicates the tasks and its levels of product stages. Outputs are managed through documentation like production reports, charts etc.., to manage the internal as well as external customers.

Process monitoring & measurement

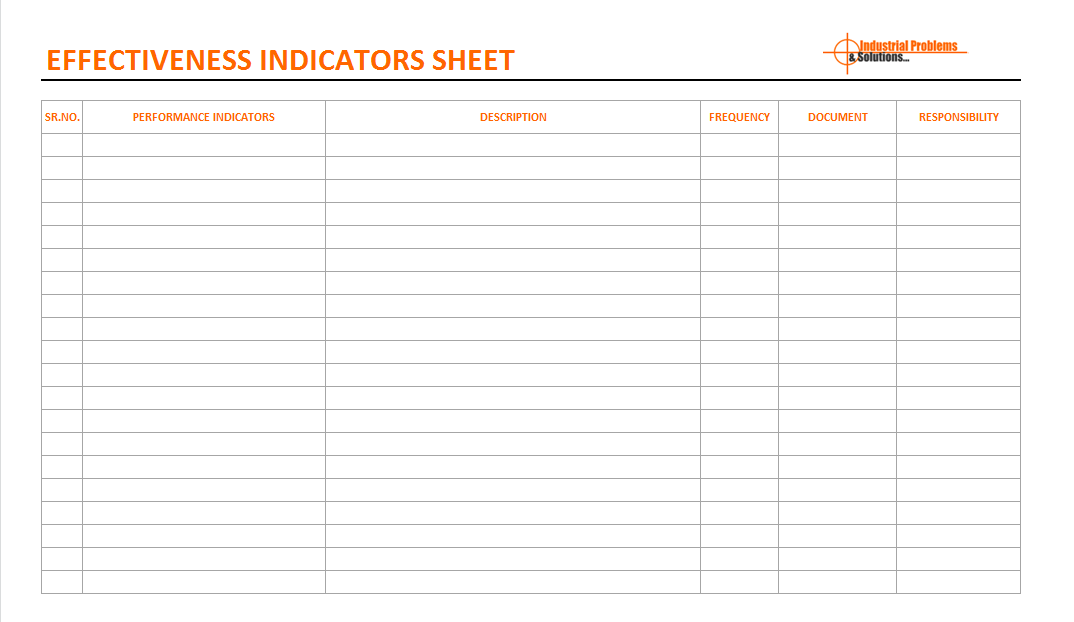

The initial step of process monitoring and measurements is to monitoring on key indicators. The team ensure effectiveness of indicators is important task. Generally, effectiveness of indicators can verify through all performance data. Team also verify the deployed processes through measuring related activities, results, and review the documents accordingly. This reviews process conducts as review frequency defined in standard practice. See below example format of “effectiveness indicator sheet” (For Education purpose only):

In the process control, focus require on its requirements. That can be in form of inputs, and supporting interface processes.

Resources and control method requirements

- Human resources management, manpower requirements.

- Quality management system documentation, planning formats and work instructions.

- Raw materials and packing standards.

- Process flow diagrams, control plans.

- Safety equipment and awareness requirements.

- Related machinery, equipment, instruments and devices to manage controls.

- Documentation and standard system to manage process control.

Implementation of process control

The process control implementation’s stages are organize for production planning, and monthly production planning. That will help to receiving inputs from various locations for verifying customer requirements. The process control process is depends regular daily planning & dispatch requirements. The process control measures are focus on material stock, daily shortages of materials and tracking of materials at each production stages.

In case any customer expecting amend the order which is already running in production. It is challenge for planning team to reschedule delivery, verify technical details, quantity or specification of materials are review again. The process control will helps to amend production planning and scheduling once the effectively implemented.

—————————————————————————-

Effectiveness indicator sheet

—————————————————————————-