Equipment Approval documentation

Guidelines for equipment approval documentation are established to ensure the equipment technical requirements & standard processes can conduct for operations.

Guideline for equipment approval documentation is document that all the equipment records are conducted and register the entry of equipment, in the guideline for equipment approval, equipment required criteria, non conformity and other conditions which are secure to operate equipment in workplaces and also important equipment should be works in workplace safely. In the equipment approval system needs to monitoring and inspecting each equipment, there are description of the equipment and all associated details should be included, model number, serial number, short description of equipment and technical details are most important for equipment inspecting and its approval system.

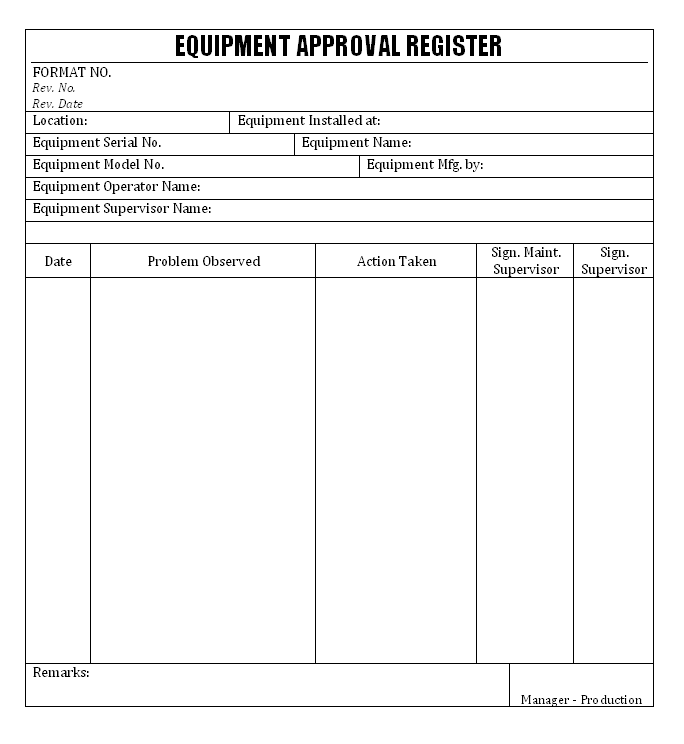

Equipment approval documentation are prepared by equipment manager for inspecting, verify information and details about equipment and approve for regular operation, for preparation of documentation, verification and conducting inspecting individual equipment in case any non conformity is identify that should be immediately conducted and on compliance of requirements that equipment can get approved for continue works. The system development is much important for operation security, safety and product quality. For the managing all the equipment and its concern details are managed in single format which is register for equipment, through the information are conducted as per equipment and system requirements, each equipment record are conducted in equipment approval register, see picture below given as example for equipment approval system, here as below given format for education purpose:

Equipment manager is conducting information of manufacturing details where technical specifications and requirements, certificates from manufacturer and other guidelines are conducted as reference of equipment approval system; In case the system requirements are for equipment test that all concern tests are conduct and results are recorded in register for compare standard requirements. To considering safety of equipment operators, properly verification of all the functions, operative functions & test the possibilities of accidents, and the manager should be active to conducting the task of approvals of equipment for regular used.

Equipment approval register are maintained by equipment manager and all the details are maintained concern equipment approval system, equipment manager is observe equipment, test and identify any non compliances are identify, those problems are verify and action plan are prepared by concern peoples, and submitted to equipment manager, equipment manager is very all the action plan and appropriate action are taken for compliance to equipment.

—————————————————————————–

Download format in word document | Excel Sheet | PDF format

Equipment approval register

—————————————————————————–