Low efficiency operator monitoring

Low efficiency operator monitoring analysis process conducted to identify cause affecting manpower to reducing efficiency in workplaces.

Low efficiency operator monitoring analysis process established to identification of sources of reasons that cause manpower efficiency low, and affecting manpower productivity during producing materials in workplaces that affecting directly productivity of overall manufacturing facility. Generally the management team is conducting production analysis data and on based of production data analysis, management team is identify lowest performance of department, unit and operators that handling machine and engaged with production activities, and its improvement of each unit, facility and individual operators production and efficiency, team is manage its action plan on based of analysis of collection of data, interaction with operators, awareness and production training & motivation though investigation of sources causes that effecting operator productivity and identified low efficiency during any period. The information are managed as per monthly of half monthly data analysis that individual operator records are also maintained and its monitoring process is established when any operator identified with very low efficiency which is not acceptable for other comparison.

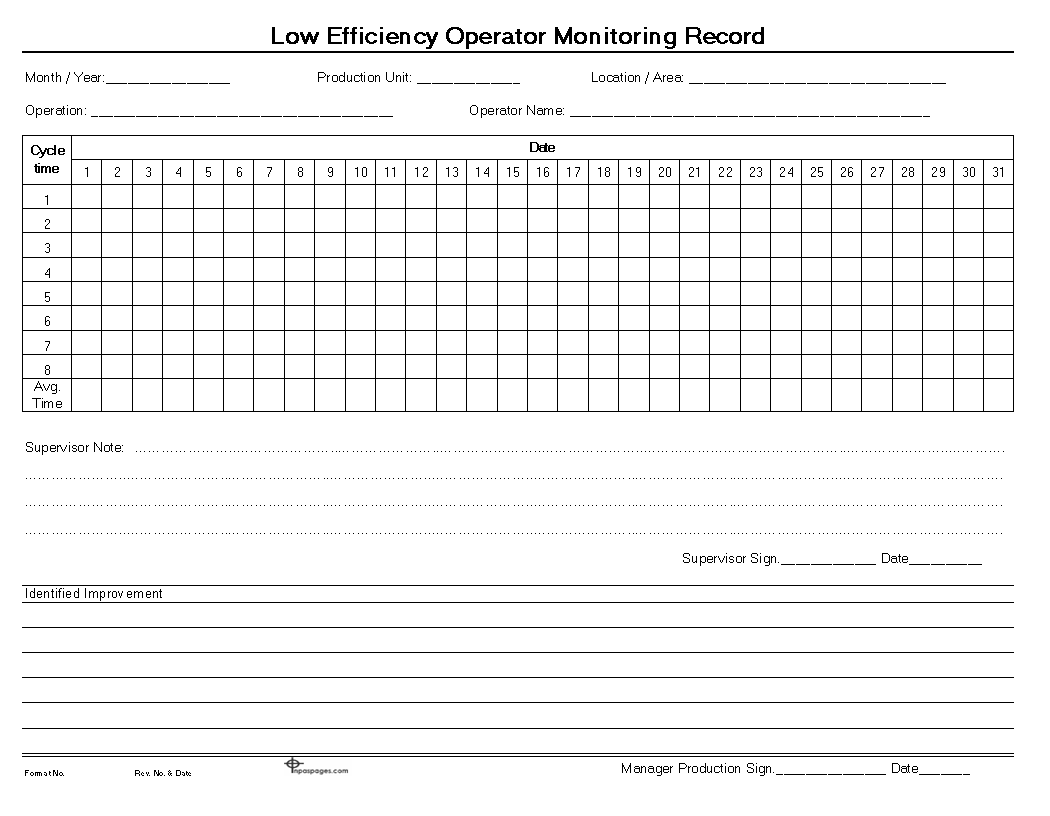

Low efficiency operator monitoring process is handled by supervisor as instructed by production manager, concern supervisors are responsible for monitoring on activity of each operator targeted due to low efficiency recorded in previous month, and its records documentation are maintained as monitoring on it. The concern department supervisors are managing records to visiting and monitoring on production lines to identify improvement points that handled individual as well groups improvement to considering internal department requirements, the improvement are in form of procedures, guidelines, instructions and sign boards etc.., and also managed awareness training to each operator to managed average improvement of productivity. On completion of monitoring of each low efficiency operator recorded are managed its individual documents and supervisor note for it, the improvement points are also needs to mentioned to concern management can determine action plan for improvement in workplaces, the production lines are managed records are compared by management to further analysis. The document handled by supervisors during monitoring of each operator, see picture below for education purpose which is can used by supervisor for recording monitoring activities:

Low efficiency operator monitoring record format is used to recording individual operator records where listed operators those are recorded for low efficiency in previous month, the department concern supervisor are monitor on each listed operators for verification of status of each operator had given instructions, guidelines, instructions and training that effectiveness are verified, and its records are managed in low efficiency operator monitoring records, this record is completed and submitted to production manager for further analysis, production manager is recording those information and provided its points for improvement against management, and with discussion with all concern team, action plans for improvement, training and changes that helpful for operators to improve self productivity are implemented.

—————————————————————————-

Download format in word document | Excel Sheet | PDF format

Low efficiency operator monitoring record

—————————————————————————-