Daily monitoring system for equipment and instrument

Daily monitoring system for equipment and instrument are established to ensure equipment or instrument works accurately.

Daily monitoring system for equipment or instrument are establish to ensure equipment or instrument is working properly and provides measurements, services accurately as defined task, the system is conducted on base of the frequently monitoring which are daily monitoring system where all required parameters or any key parameter are measured and daily monitor to ensure equipment, instrument or device can able to serve in process. Equipment, instrument or devices are used in various manufacturing and its supporting processes, mostly used in quality to conducting inspection processes which are used in product measurement and assurances that needs to perfection in measurements hence there is no change of any various in the measurement of devices, equipment or instrument can cause the serious quality issues in product.

Daily monitoring system deployed by quality department to ensure equipment, instrument or device accuracy and quality department is responsible for quality concern issues and equipment are used in process. During the quality inspection any equipment, device or instrument is serve wrong measurement can cause mixing of non standard product with correct products that means no any motive are fulfilled of quality checking of product, so for the quality department each equipment, instrument and devices are perform with minimum tolerances which acceptable for quality and product requirements and the standards of measurements accordingly.

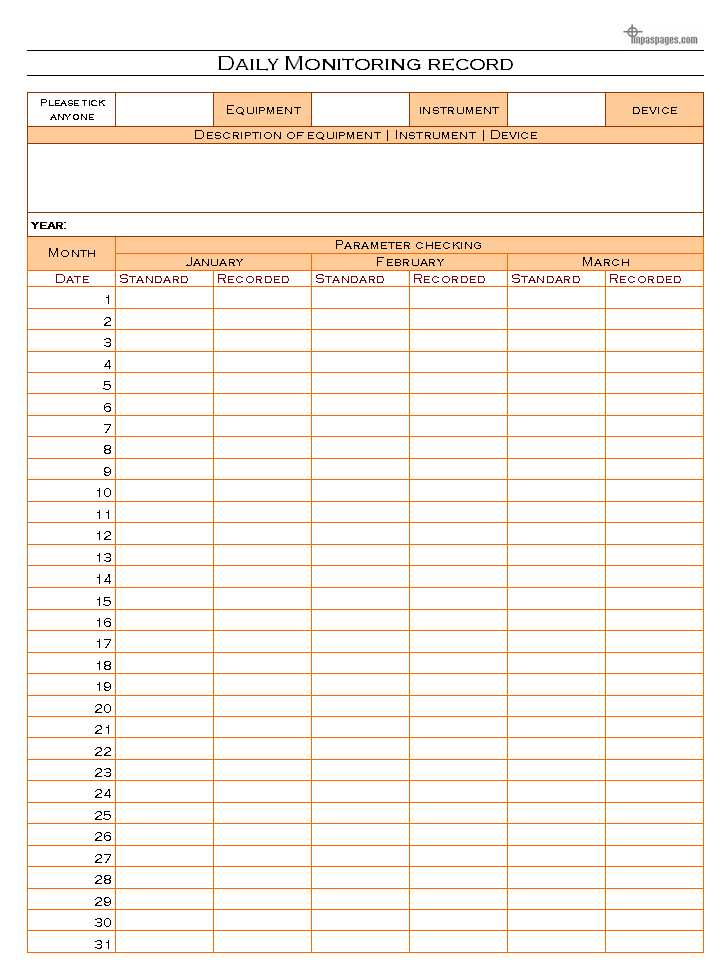

The purpose of the daily monitoring system is to identification of the quality measurement devices and equipment are frequently used in production lines and for manufacturing processes concern, in the manufacturing equipment, instrument and devices are also used for the quality checking of the product which are in process quality checking or sampling checking, but its also important that each devices are used in manufacturing and quality department should be perfectly works to ensure product quality. Quality department are conducting equipment, instrument and devices monitoring daily and its records are maintain separately, the information of equipment and other measuring devices are recorded in single format which is daily monitoring records, see picture below is reference format and given for education purpose:

Daily monitoring system are established by quality department and its records are maintained daily basis, and every day quality head should be verify the record to concentrate on any equipment which is not maintained its standard parameter during day, in the next two day the condition of the equipment, instrument or devices are indicate not as per standard requirements that quality head will be immediate in action and replace it and deploy new one which is properly calibrated, the system is required for quality maintain of the product and also for improve quality inspector’s confidence. Daily monitoring records format which you can see as above can maintain for three months, its can also manage as per parameters requirements, here are imaging that most important parameter which can affect product quality is considered and format is created, but the quality feel that more than one parameter of equipment, instrument or device need to monitor that parameter wise or to include more fields for the parameters to proper monitoring individual parameters of quality measuring.

——————————————————————-

Download format in word document | Excel Sheet | PDF format

Daily monitoring record

——————————————————————-