Daily material defect review record

In manufacturing processes material are producing by support of various processes, in some process product are became a defective or rejected due to some reasons or due to raw material defects product are rejected that raw material defects are on first test are not possible to identify that during the process material defected due to on process, all the defected material are recorded in the manufacturing unit, production peoples prepare report on all the material defected during the process and after the end material defects report is became a daily material defect records. This daily material defect records are simple data that material identification number, time of defect was identified, type of defect, who was the operator on time of defect was identified, at which department this defect was identified, and description of the defects are conducting on base of the records that became review when all the records are merged in the single format which daily material defect review records to management can analysis on the record to identify what is reason of the defect in the product, this review helps to find raw material defects, in process defects, equipment / machinery defects or miss configuration of machine or by mistake of human. On base of records management get the reporting to easier for decision for the improvement to possible eliminate in process defects and defect which is comes from the raw material can possible tracks.

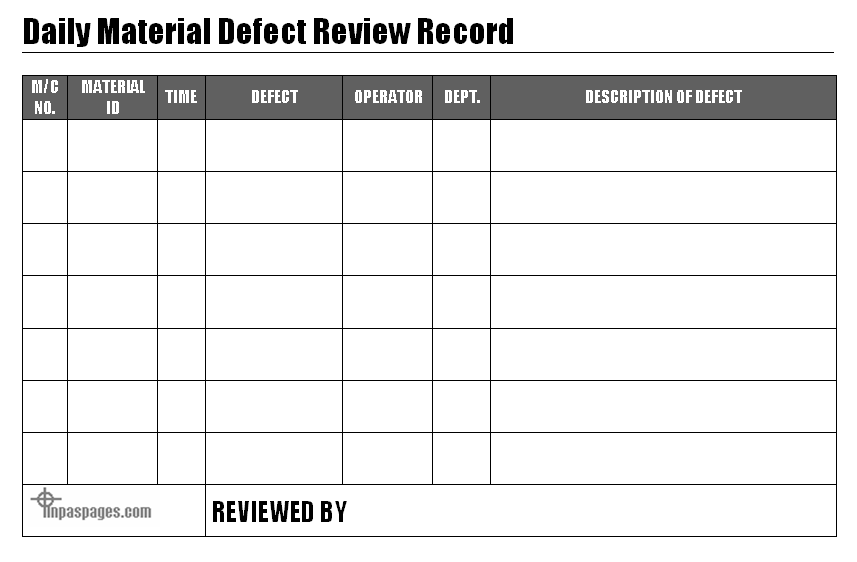

Daily material defect records are collected by plant supervisors with report of the individual report of defect to submitted to plant / works manager, manager analysis all the report which is merged in daily material defect review records analysis for the identify numbers or defects / which defects are occurred at which place and which machine etc., helps to manage defect review. Here as below given format for daily material defect review record for reference:

Daily material defect review are conducted on daily basis, its can review by daily evening after shift ending or next day morning when all the data are collected form the manufacturing processes, each data of the material defects is very important for the analysis, each day evening all the data are submitted by department supervisor of material defect report, this report is base of the analysis. Daily analysis is required for eliminate possible defect on next day.

Reviewer collecting the entire data & separate defect wise data for the analysis and same for the material, operators along with its quantity, which is mentioned in description of defect. On base of the defect wise records are helps to root cause of the defects with the material, see below example helps to understand it:

| Sr. No | Defects | Qty | Defect Description |

|---|---|---|---|

| 01 | Spots on material surface | 02 | Spots on material surface are due to raw material |

| 02 | Spots on material surface | 01 | Spots on material surface are due to raw material |

| 03 | Spots on material surface | 01 | Spots on material surface due to machine role setting |

| 04 | Spots on material surface | 02 | Spots on material surface during material movement |

As per above example, All defect wise data are merge in single sheet to easier for the analysis, here as above 50% of defects are due to raw material, so management are take the necessary actions on the raw material inspections, raw material purchasing and movement during the process to eliminate or minimize defect during the process.

EXAMPLES, SAMPLES & FORMATS

DAILY MATERIAL DEFECT REVIEW RECORD IN WORD DOCUMENT DOWNLOAD FREE

DAILY MATERIAL DEFECT REVIEW RECORD IN PDF FORMAT DOWNLOAD FREE

DAILY MATERIAL DEFECT REVIEW RECORD TEMPLATES DOWNLOAD

DAILY MATERIAL DEFECT REVIEW RECORD IN JPEG, PNG FORMAT DOWNLOAD