Daily compressor inspection and records

Compressor inspection process is conducted to ensure the all part of the compressor and functions are working properly to serve installed lines.

Compressor inspection process and its concern activities are conduct by maintenance engineers and supporting team to conducting the routine schedule of inspection, the compressor works and its functions are identified by the maintenance engineers and on base of the checklist concern maintenance peoples are conducting or engineer is inspecting the process of compressor where check out all the parts, functions, lines and others concern requirements as per identified for the inspection by maintenance head to ensure all the function of compressor is working properly and not required to any further actions, in case during the inspection process, maintenance checking team identify any non conformity that immediately compressor taken in the maintenance or put the out of work until required process i.e. maintenance process is conducted. Generally the system should be checked that is in general working order as needed daily basis but in case the company fills that requirements of the checking and its frequency can be manage on every two days or four days of the week.

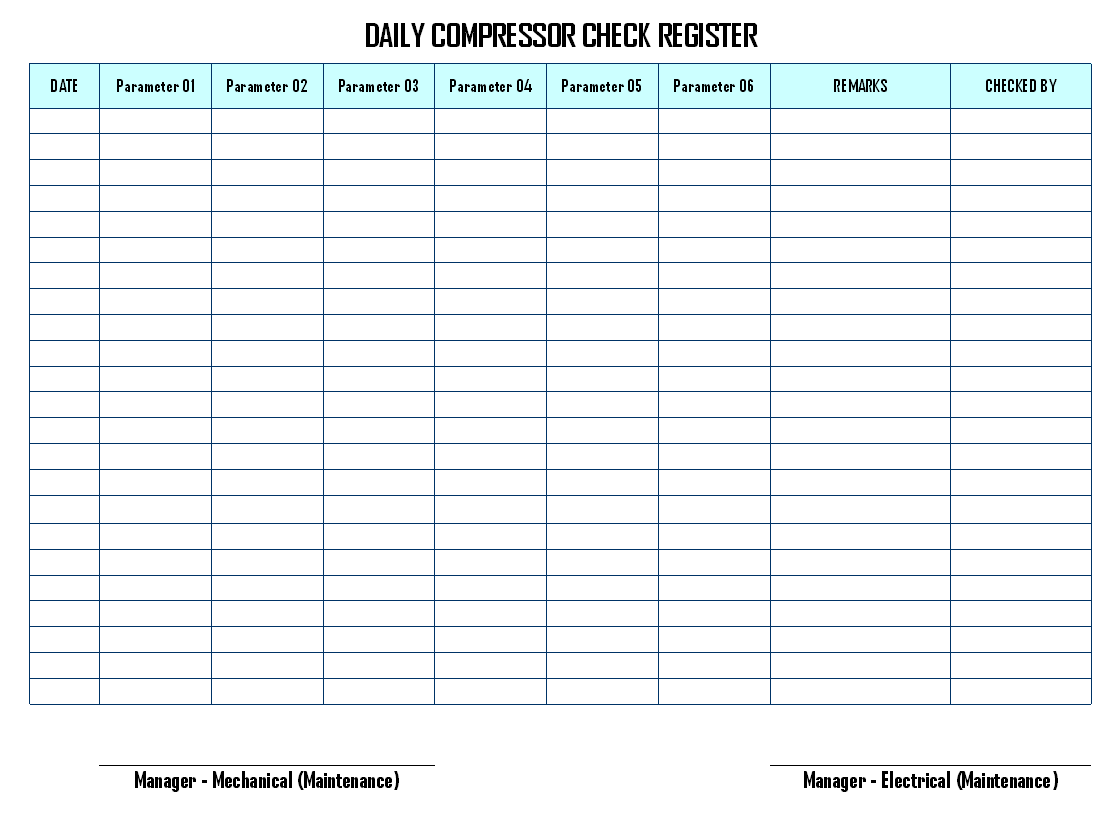

Compressor inspection process owner is maintenance, conducting inspection process, approvals of all concern records and others permission is in maintenance head responsibilities and authority. Compressor inspection process is conducted under observation of maintenance manager and all the decisions and actions are approved by maintenance manager. Compressor inspection process are on base of the compressor functions and parts all the parts of the compressor is checked and verified functions is properly works that should be important to check out minor areas of compressor to ensure the functionalities are properly able to serve the installed lines. For the conducting the process of compressor inspection, required document to which having a ready format to checking base on given parameters for the functions of compressor and records of the daily compressor check are maintained in register, see picture below:

In the daily compressor check register is maintain the date wise activities that is daily activities of the inspection of compressor, this register is maintain records of the inspected all the functions of compressor and its parts individually, see above given parameters wise record information can register to identify the error / non conformity of the function of compressor, all the records are maintain daily and same as verified by maintenance manager to ensure the function of compressor is working to operations.

Generally in the daily compressor inspection are conducted following types of the inspections are activities:

- Checking of compressor oil level

- Visual checking of compressor belts for any damage

- Open tank bottom drain and blow out water

- Visual check that the dryer unit is working properly.

- Visual check in line moisture and line filters in air compressor mostly.

Compressor inspection and regular checking is very important for the maintenance activities, each compressor of the unit is checked daily and its required maintenance process should conducted in case of a failure or damage identified that is to determine corrective actions needed immediately.

———————————————————————————-

Daily Format for Word document | Excel Sheet | PDF Format

Daily compressor check register download in word document

———————————————————————————-