Countermeasure Method : Quality Assurance Techniques

A countermeasure is rechecking method or an action that can be in form of process, device deployment or system that prevent defects in the quality of product.

Countermeasure is the method of quality assurances and controlling for mitigate defects, mistakes in the product to prevent against quality of the product, countermeasure method is the actions that can be in form of processes – the manufacturing industry mostly in automotive industry, engineering industry, information technology and other concern heavy machinery manufacturing industries are calculating the products measurements for the assembling and constructing on huge count which possibility is much to leak the system and result the mismatch measurements are required to specifications of the product, for the prevent the mistakes, errors and defects in the product quality countermeasure system is need to deploy for the maintain stabilities and uniformity in product quality. Countermeasures can be inform of the devices that deployment of the devices to mitigate possibilities of the mistakes or defects in the product quality or in form of the system or process that helps to counting of measuring system is effectively works that does not required to worried about quality stages.

To prevent or mitigate problems by countermeasure method for maintain quality of the product, the system processes & activities during the manufacturing the product some errors occurred that all are rechecked or identified for the correction. Countermeasure is system that helps to managing and adjusting the situation on defects identified. Its totally quality concern and measuring activities that happen due to producing the materials or defected during the assembling processes, hence quality is prime responsible for the corrective and countermeasure of the product and also production department is responsible to maintain specifications requirement during producing material.

Countermeasure method is used for the identify potential problem in the product which is directly concern with product quality, this method is simple and its nothing different much to quality inspection but this process is provides advantages to prevent the mistake before repeat and its impacts are noticeable. For the implement in the process system of countermeasure required to primary identification of the process system inside problems and treat which is making the process variations that here as below example is helps to understand which types of problems analysis helps to implement countermeasure method in system and how it is required.

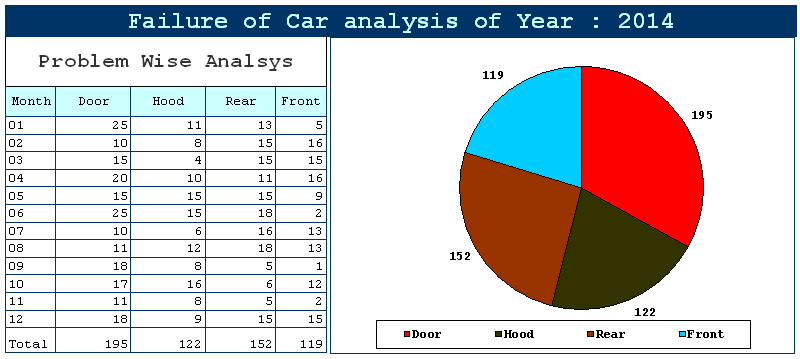

Example: Any car manufacturing company analysis helps to understand the problems separately handle after on results of the analysis, here as below given problem graph in the total problems are which is higher and what actions are required on which problem, on base of the problem manufacturing team is consider the higher problem values on priority to eliminate by counter measure method:

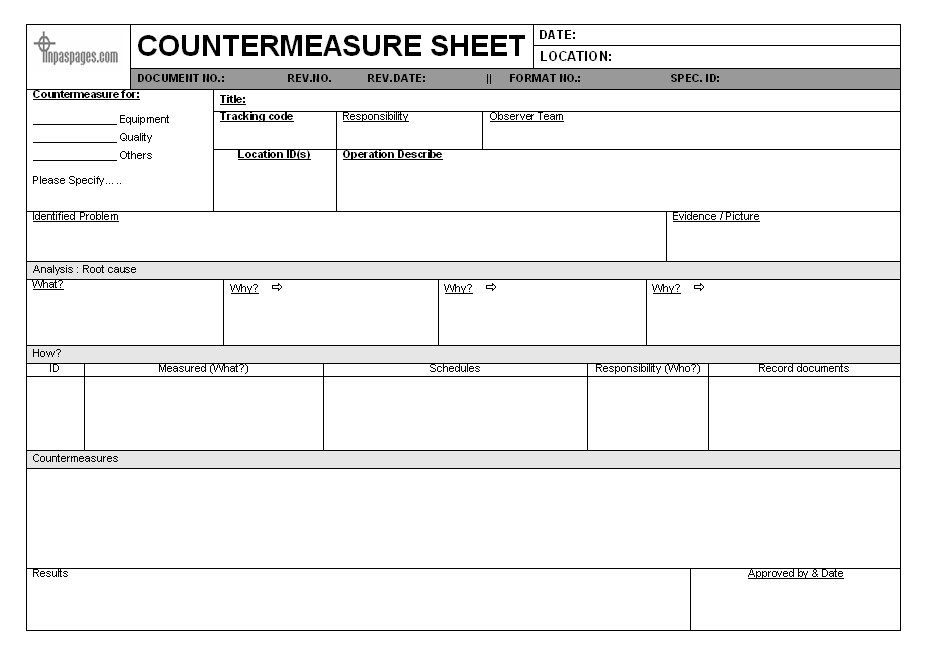

Generally in the countermeasure method is covered all the concern information of the requirement to identify and tracking the product, but the main important that team should not what type of the countermeasure is conducting that can be equipment countermeasures, in case any heavy equipment or machinery manufacturing company is conducting countermeasure for the identification of the problem and prevention against problems, there are also possible only considering the quality of the product and equipment countermeasure or part of the product is being countermeasure.

Identified problem is very first step of countermeasure takes by team that all the identified problems are conduct to the understand the and analysis of the problem to go in deep for the better consideration of the solutions, identified problems types, impacts on other part of product all are measured, in the countermeasure method used statistical and mathematical views for the understand and deep analysis of problem:

Example:

If the car is the product for car manufacturer, and during the inspection identified that car’s door is not properly fit with body its level is difference indicates on primary view. That means the identified problem is – door is not properly fit on body hence how much and what is level? Is subject of countermeasure? Yes after the identify concern problem team is identify level of differ with body to door, like 1.5mm diff. with body’s which part level etc, this is deep problem identification to easier for the production team to understand what is measurable values for correction.

Analysis cause is finding of cause of identified problem, when car’s door having problem that in analysis cause is conducting the deep analysis of the problem to identify the root cause of the problem, root cause analysis is conducted on base of the simple method is why- why analysis – in the why-why analysis is best way by root at source of problem.

Countermeasure of the analytically data are collected by team along with the source of the problem, countermeasure is conducted by team to reach the problem sources and conducting the countermeasure method to effectively solution of the problem. In the countermeasure method this step is taken to considering the values of the measured by previous information with the inspection schedules and conducted by whole process along with reference documents, on base of the countermeasure method is effectively implementation is possible. Here as below given the format of the countermeasure sheet to easier for understand the method is used in the system to prevent the mistakes in system:

Team is collecting the information from the various concern processes and fill up the format sheet to analysis of the information to reach the proper solutions, countermeasure method is the conducted on base on results like the problem is identified as mechanical or electrical?, if the mechanical which part is effect in the product and all the possible measures are conducted, analysis and decided for permanent solution.

————————————————————–

Download format in Word document | Excel Sheet | PDF Format

Download Countermeasure sheet

————————————————————–