Calibration rejection process

Calibration rejection process is established to manage rejected equipment / instruments during calibration process to organize separately on remove from system.

The process is established for conducting rejected equipment / instruments or devices during calibration process, that conducted by quality department. Quality department is conducting calibration process for each equipment, instruments and devices as per frequency defined, during calibration process in case any equipment / instrument identified as rejected or any parameters are not matched or equipment, instrument or device is not accurate as required tolerances and range that calibration project is declared as rejected and managed rejected equipment, instrument managed separately. Calibration rejection documentations are prepared and maintained for conducting equipment / instrument for repairing or remove from system by quality department.

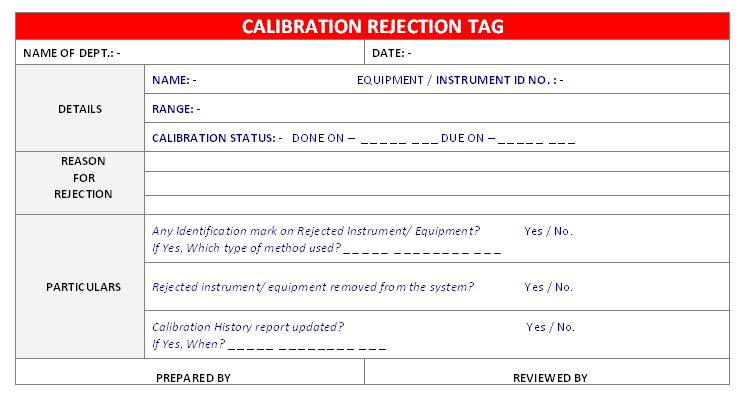

Calibration rejection process is established by quality department, quality manager is responsible for arranging calibration process, identify calibration requirements, selecting qualified engineer that conduct calibration process for maintain calibration system for equipment / instrument which is used for measuring of product during various process of the manufacturing. The process records are maintained on calibration completion, the records of calibration rejection is maintained by engineers and verified by quality manger. When any equipment / instrument is identified as rejected that needs to manage separately in the workplace to avoiding mixing of malfunctioned instrument in running process that needs to proper tagging on equipment / instrument, see picture below given as example format for calibration rejection tag which can used to tagging on calibration rejected equipment / instrument, see below format given for education purpose:

Calibration rejection tag is managed when any equipment / instrument is identified as rejected, quality department conducting rejected equipment to managing tag on each one and handled separately, once the equipment / instrument is conformed for repairing or needs to complete remove from system that calibration rejection tag is removed and conducted further process, in case after repairing equipment / instrument is maintained its range and accuracy that quality department is conducted for regular process otherwise its needs to remove from system.

————————————————————————-

Download format in word document | Excel Sheet | PDF format

Calibration Rejection Tag

————————————————————————

Related Post: