Machine management is coordination of processes, and activities engaged with automated devices, to producing materials.

In the production lines, machine management is necessary activity and part of production management. For engaged machine / automated devices to producing materials. As well as supporting activities, and resources at workplaces. As per customer order and expectation for product quality.

The procedure is conducted for all existing machine as well as new installation. Mostly for the new installed machine management are conducted on priority to setup at workplaces. To conduct rhythm with existing machine, and all the parameters setup are verified and managed accordingly.

The procedure for machine management & its deployment of processes for machine management are conducted as per requirements and will be different. The new machine management and existing machine management having a much different hence the proper guidelines, instructions to all management team by concern authority and provides procedure manuals for installation to setup and verification of each machine managed in workplaces.

Existing Machine Management

The management is responsible for the provides resources to handle the machinery, equipment and supporting resources to conduct tasks of machine management in production lines, for the existing machine management needs to setup monitoring and controls to each machine run in line with requirements and as designed for production lines.

See below points that needs for managing existing machine.

- The annual machine verification plan should be needs to conduct by production head, once in the year or twist time are recommended.

- The instructions notes, work instructions should be defined and implemented to cover the machine verification requirements as per planning.

- The preventive maintenance should be prepared & conduct as per scheduled, hence the schedule is prepared & followed by maintenance team, product head is equally responsible for monitoring and verification of each maintenance activities and on after approvals the preventive maintenance cycle should complete.

- The tooling modification is to be carried out as per process improvements and enhancement.

- The process change, engineering change or management change are effected the machine management, hence all the effected changes should covered on discussed with management, quality, engineering and maintenance team to effectively implement occurred changes.

New machine management

As the same management involvement in the machine management is important to effectively engagement of machine in production lines to improve productivity and resources reliability. The new machine management needs to more effort to considering production requirements, process requirements and layout of production lines.

See below some points help to understand the machine management:

- The new machine management is conducted for new tools requirements as per advance product quality approval system where all the requirements for tooling is managed and implemented accordingly.

- The team should considering new machine requirements, and prepared the drawing. The drawing preparation and implementation is conducted by development engineers.

- The machine drawing as in inputs for the machine further implementation and management.

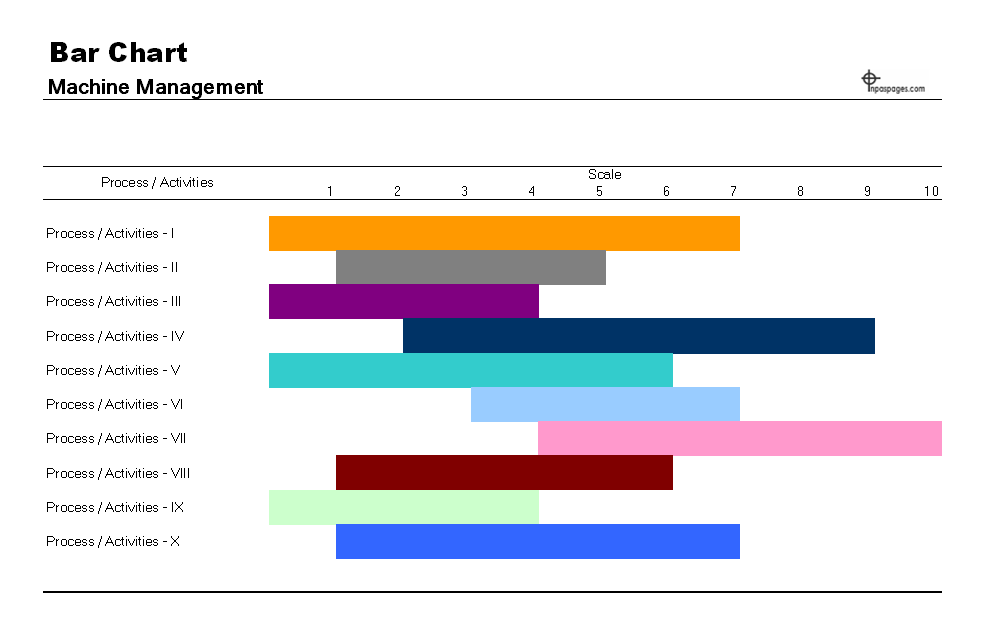

- To manage new machine needs to prepare bar chart to organize the production lines, processes and schedules and sequences of processes.

Bar Chart

- See picture below of Bar chart

- The processes can be done through both the suppliers either it can out sources or arrangement of in house manufacturing.

- The next management part is to discussion with the plant manager for communicating with the supplier / manufacturer for the technical discussion for the tooling and other services. Hence the issues & layout discussion are involved in the meeting. And effective follow up of supplier processes.

- Machine inspection, audit should be conducted as per defined and implemented drawing.

- Quality assurance team & production peoples are jointly conducted the machine trails to ensure the product quality and customer requirements. The trail reports are submitted to quality assurance manager and management for approvals and further actions.

- Once the approvals of quality assurance manager and management, work instruction for the machine and supporting activities are managed, each work instruction are needs to display at the front of the operators, operations should be covered in work instructions as per index new machine lists.

- On completion of the machine management, the team is handover the machine to production department for conducting regular tasks.

As above mentioned machine management process is general. It can used for small scale industry Mostly. The processes for huge production lines are still same the processes. But some tasks needs to add in inline with production requirements.

———————————————————————–

Download format in word document | Excel Sheet | PDF format

Bar chart

———————————————————————–