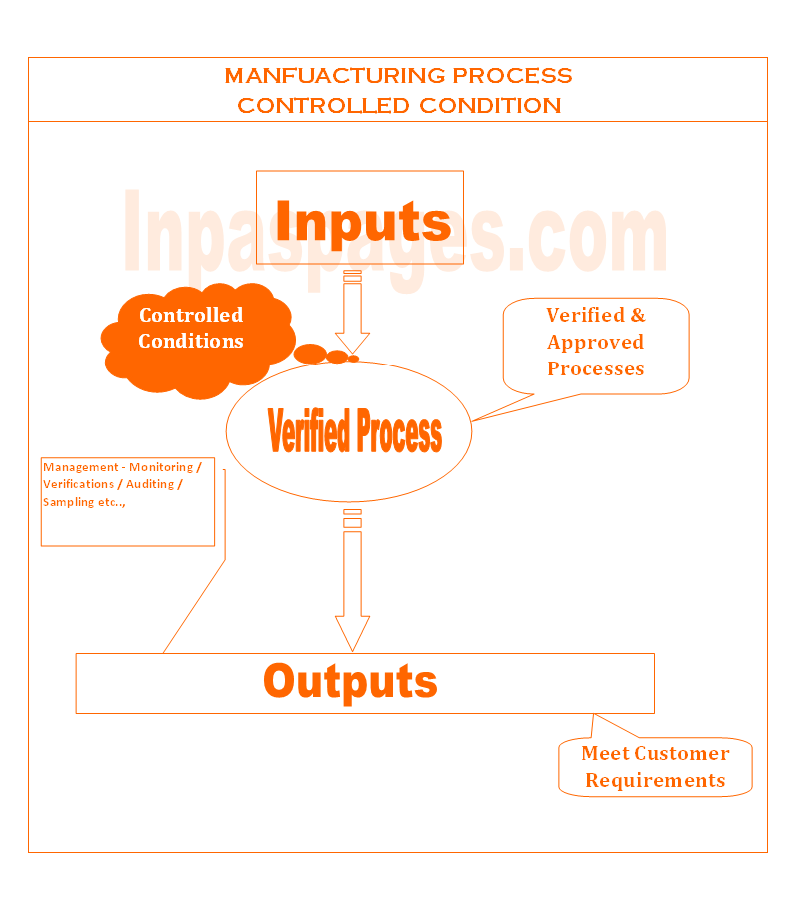

A controlled conditions for manufacturing process may contain identification, planning and implementation. It may also help to ensure the manufacturing process is performing under controlled conditions.

Introduction

The guidelines for the implementation of proper controlled condition in the manufacturing processes require to verify the each concern processes. The purpose of processes is to maintain for inspecting, verification, implementation and sustain as per controlled condition requirements.

The processes are maintain as procedure requirements that are identification, planning and schedule of requirements and execute manufacturing processes. It may also help to ensure that the all manufacturing processes are carried out under the controlled condition.

The system helps to maintain and implementation. The procedure is conduct as per standard requirements. Normally, standard requirements are maintain as per international standards requirements, product standards and specification, technical requirements of customers as per end applications and characteristics. It may consider for the establishment of proper guidelines, instructions, procedures and same for the implementation of procedure.

What can be initial process?

The procedures and its concern compliance is implementation, follow up, corrections, monitoring and controls are require. Hence the responsibility of all concern department managers should involved in the manufacturing processes. Where product concern with quality that affecting requirements of end product.

The procedures implementation for the identification of requirements, proper planning and schedule. Its concern requirements, and manage to ensure the manufacturing processes controlled through proper documentation.

Work instructions, procedure and guidelines as per specific documents like formats use in various processes. The documentation and its regular tasks are manage by concern department management. They will conducting various processes on various levels. That each order receive from planning department is managed order & reporting to implement procedure.

The requirements of customer order is verified and concern bill of materials are manage. The concern documentation are manage accordingly. The maintaining concern required inventory in production lines are part of product process and its controlled conditions. Hence the requirements and its notifications are managed accordingly.

At the production lines

The initial requirements for the production lines are manage as communicate with concern department. To inserting materials as work instructions and planned. During the various process in case any non-conformity are identify that needs to department head is confirm the each non-conformity.

Identify solution inline with requirements. Hence the documentation for the production processes. And its implementation are manage as per documented procedures. The system needs to manage in internal management system. The documentation for the procedures are manage accordingly, the flow for the manufacturing process controlled condition is manage as per below picture.

The picture below is provided for the reference, and education purpose only.

—————————————————————————–

Download format in word document | Excel Sheet | PDF format

Manufacturing process controlled condition

—————————————————————————–