Measurement system analysis (MSA) is statistical technique to determine the variation in the process or product. MSA help to measure the parameters and criteria that may help to ensure the actual tolerance of product or process. The MSA investigation may include the BIAS, Linearity, stability, R&R (Repeatability & reproducibility)

Introduction to MSA

Measurement system analysis (MSA) planning, schedules, action plans and its concern documentation are prepare, maintain and update for managing various tasks concern quality assurance. Its step by step documentation are maintain to recording information of measurement system analysis planning. The action plans that raise for improvement of quality assurance tasks. Quality controls tasks to achieve quality product, in process measurement system. Its controls deployment are manage, the measurement system analysis (MSA) planning.

Its schedules are handle to conduct all measurement instrument, equipment and devices. To verify and implement accuracy of each measurement equipment to ensure the product quality. MSA process is maintain to conducting each measurement instrument, devices and equipment verification, improvement. Even the calibration processes are cover to ensure the measurement instrument and equipment are performing accurate during in-process inspection.

Planning of MSA

The raw materials and finish quality inspection processes to measurement product for quality and dimensional checking and verification. The process for measurement system analysis (MSA) and its planning are manage as per frequency define by management. To conducting product and its specification, parameters and dimensional study, each planning and activities having its own MSA code. To tracking and monitoring on implementation of each process separately.

Measurement system analysis (MSA) planning, schedule and its implementation process and its documentation are manage by quality department. The quality manager is responsible for conducting all tasks concern measurement system analysis.

Measurement instrument and devices as well as all equipment that use to conduct process of measurement to verify product quality during manufacturing processes. The quality manager is handling and implement all the processes concerning measurement system analysis.

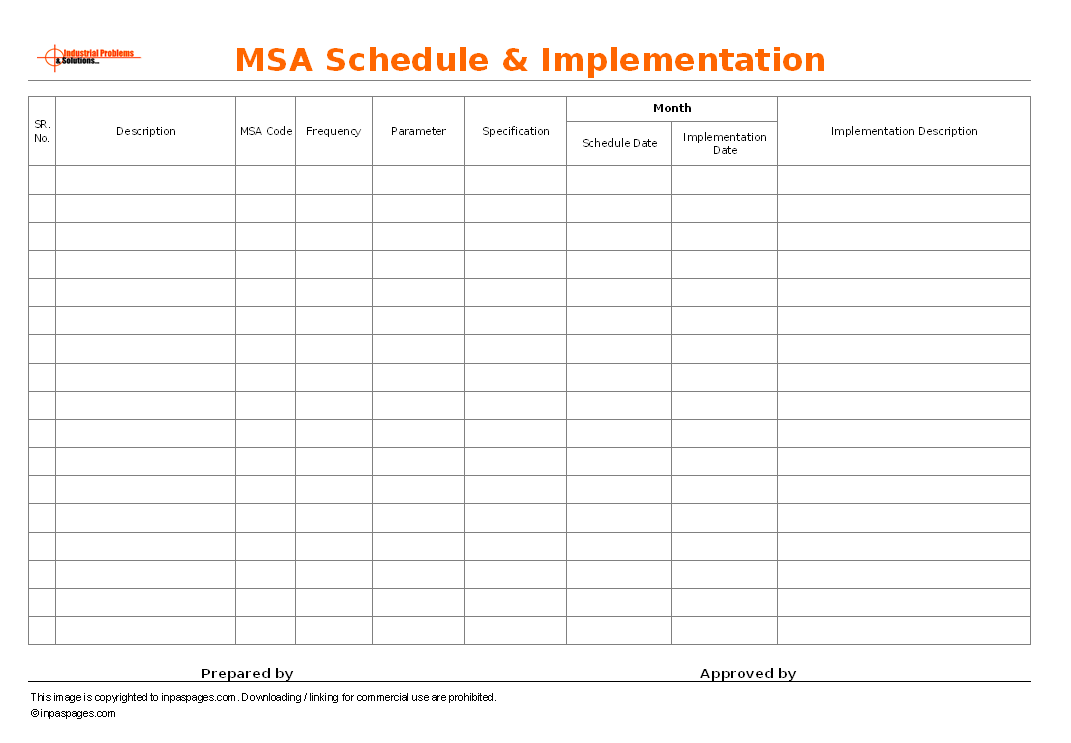

The deployment of planning for measurement instrument, system analysis of each instrument is verify, deployment of procedure, concern processes and guidelines. To each quality inspection are manage by quality manager, as well as monitoring and controls over processes during regular tasks to implement accordingly. See picture below given as example format of MSA schedule & implement sheet for education purpose:

MSA schedule & implementation sheet format

The MSA schedule & implementation sheet format is use to recording information of calibration process. As well verification of each measurement instrument, devices and equipment use for managing dimensional verification. The inspection, product sizes and other measurement processes are conduct by equipment are manage in measurement system study. Its analysis processes to ensure each measurement equipment use in manufacturing and supporting activities are accurate. To ensure reliability on measurement equipment that use for measuring product quality as per standards requirements, technical requirement of customers and end application.

The documentation for measurement system analysis (MSA) planning and step by step implementation are manage as per schedule i.e. frequency define by management. The process are manage as per month base, and its monitoring is conduct as per record in this sheet.

——————————————————————————-

Download format in word document | Excel Sheet | PDF format

MSA schedule & Implementation

——————————————————————————-