Raw material tolerance analysis is the general process for the study for identification of natural variations and tolerance of the materials. It may ensure the tolerance is in acceptable level. Generally the most of the businesses are using the methods to ensure the raw materials quality is meeting the standard requirements.

Introduction to tolerance analysis

Raw material tolerance analysis is establishment needs to managing all incoming raw materials use in manufacturing activities as prime mother product. The proper inspection, monitoring and controls over standards, technical and customer requirements are consider.

During purchasing and on receive materials at raw materials storage areas are verify, inspect for identify raw materials intolerance. It may include product dimensions, sizes are measure for proper monitoring and controls over raw materials standard requirements.

Role of quality team

Raw material tolerance analysis are prepare by quality department. The quality team is conducting raw material tolerance analysis to collecting information of raw materials. These are needs to use in production lines, the materials are conduct for inspections.

On base of inspection records further analysis is conduct. Quality analysis team is gathering information from quality inspection team. The records and its concern documentation are manage for analysis. Where all the records are conduct in documents for analysis.

Analysis Process

The analysis held for identify raw materials tolerances where dimensions, sizes and other parameters categories to ensure the product purchase are comply all standard requirements. About of raw materials standards where each products are needs to verify and analysis.

To ensure the product quality and compliance of quality requirements. The records of raw materials are conduct for analysis where standard product that is raw materials tolerances are consider in middle of quality requirements. Because of standard requirements of end application.

The raw material tolerance analysis is conduct to handling product tolerance as parameters. Mostly engineering products are considering and its product standards needs close tolerance of product that comply end application requirements. The analysis is also carry out evaluation of two or more raw materials to batch or lot comparison of tolerance to ensure the raw materials is acceptable as per product technical necessities.

Documentation

Raw materials tolerance documentation & analysis is conduct quality analysis team. The quality department head is responsible for effectively monitoring & controls over process of raw material. Tolerance inspection analysis and its concern documentation.

The analysis process carried out on base of quality engineers’ primary inspections that is measurements of each raw material. The inspection process handled visuals and physical measurements are conduct of each number or unit. To ensure the product tolerance i.e. raw material tolerance.

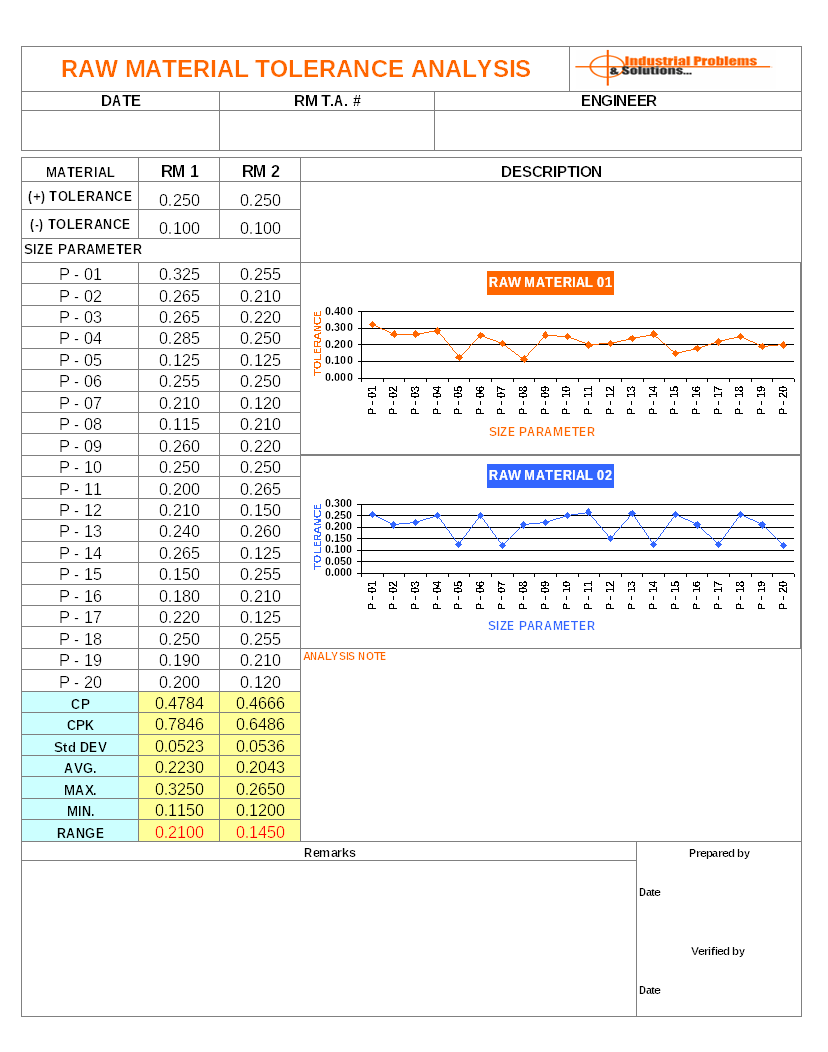

The quality inspection team is conducting information data during inspection process on general inspection sheet or report. Hence analysis team is verify details of each documents and establish raw material tolerance analysis. See picture below format for education purpose:

Raw material tolerance analysis format

The raw material tolerance analysis format is use for recording information of analysis held by quality analysis team. The records are manage to identification of variation in tolerance of raw material purchase for producing materials as customer’s requirements. Raw material tolerance analysis format is cover analysis requirements where concern engineer name is need to mention.

Quality engineer who had conduct dimension checking of each raw material and provide primary data of measurements conduct in raw material storage area.

The records are maintain for the each material, see the picture above having rm1 and rm2 are different products and its size parameters that is tolerance are mention respectively are use for comparison.

To easier for identify which lot or batch having better quality & which having needs enough attention for finish product requirements. The analysis documents are maintain, update and storage for as per documentation system. The disposal are conduct as per retention period defined by management.

————————————————————————–

Download format in word document | Excel sheet | PDF format

Raw material Tolerance analysis

————————————————————————–