Efficiency monitoring

Efficiency monitoring process is conducted to verification of each machine and process that utilized manufacturing activities & produced is managed.

Efficiency monitoring process is established, maintained and conducted by concern authority to verification and identification of the hourly efficiency of each machine and concern process installed in the manufacturing facilities to analysis of utilization of each machine, equipment, manpower and processes that utilization and engagement in manufacturing activities, and producing materials are managed & recorded for the improvement of each machine and process efficiency to overall productivity improvement of each production lines in manufacturing facilities. The efficiency monitoring process is established and conducted to identify machine / equipment or process errors that can be visible or in hidden format that easily trace to verification of efficiency of machine that working low than its capacity are managed by maintenance activities, verification and identification of errors in machine are conducted and resolve it issues to run smooth with sufficient capacity in manufacturing process. The analysis team is conduct each operation handled by production lines are verify and frequently monitored on activity & collect the records to identify hourly efficiency, generally production manager is responsible for collection of information from production lines to analysis and identification of hourly efficiency, and on completion of day tasks that whole days hourly efficiency are managed and average efficiency are identify as day efficiency of particular machine, operation or process that handled during the working hours at particular machine or production line.

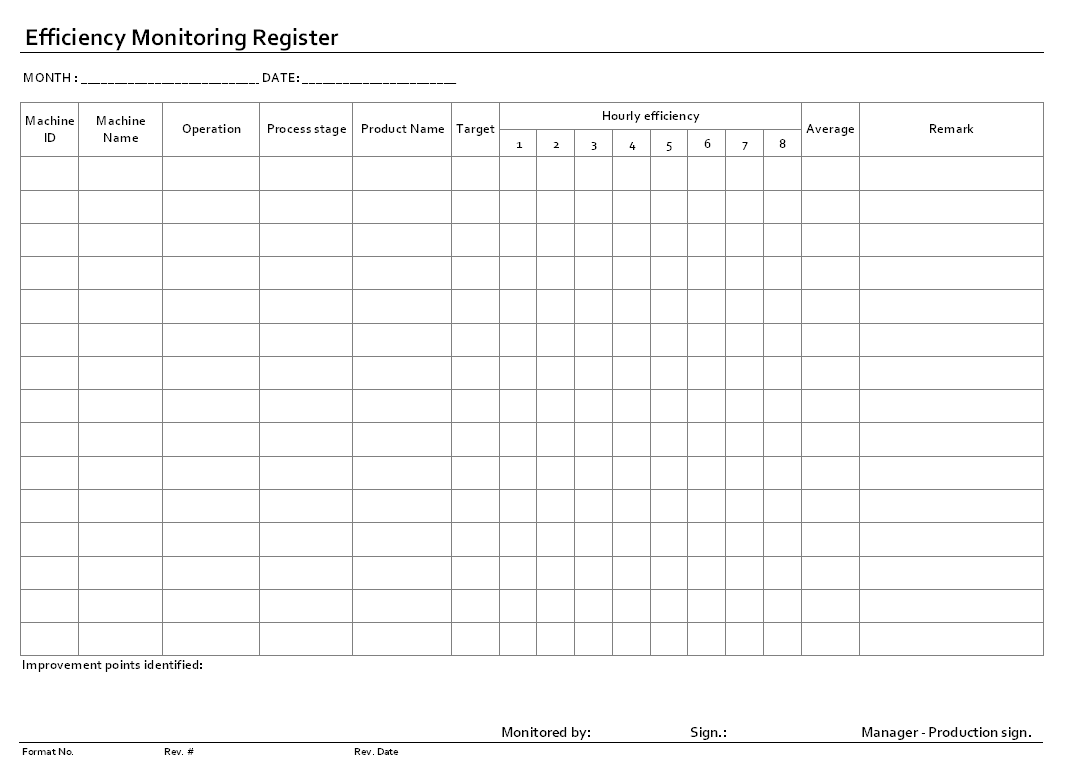

Efficiency monitoring process documents are established to managing records of efficiency of each machine, process and operation that conducted in manufacturing facilities, the each process stages are conducted by production manager to monitoring and verification of the process efficiency and collected information are collect for analysis, the records are maintained of each efficiency identified and monitoring required, see picture below given as example format efficiency monitoring register for education purpose:

Efficiency monitoring register format is used to recording information of each machine that used in production lines and engaged with producing materials, operations and processes that handle the materials that should be well organized & productive that manage costing, time management are identified through identification of hourly efficiency of machine, and the concern management is frequently monitoring and identify hourly efficiency to achieve the targets that expected for each hour or as average of the day. Efficiency monitoring register format is used to managing records with each process stages, operations and its monitoring are conducted for analysis and improvement of productivity and overall improvement of process.

—————————————————————————–

Download format in word document | Excel sheet | PDF format

Efficiency monitoring register

—————————————————————————–