Product trail document

Product trail document describe information of process to manage quality trails on product in manufacturing process.

Product trail document established to managing information from various department to collecting of processes conducted for verification of product quality, product standards and customer requirements as product trail during manufacturing processes. The process is conducted for verifications of product is under manufacturing processes that as the sample processes on the finished product is conducted for testing to easier for identify requirements of quality to improvement of in-process manufacturing specification requirements, the processes of product trail is important part of the manufacturing processes that managed by quality personnel. The purpose of product trail is to ensure that the product under the manufacturing is compliance all the requirements of the product standards, customer requirements and concern parameters that need to manage for technical requirements and end applications, this process is managed by quality personnel and part of the quality assurance and controls over the product manufacturing, in producing materials needs to verify the product to provides assurance of product are meet requirement of end application of customers with all close tolerance provided as requirements for the concern application.

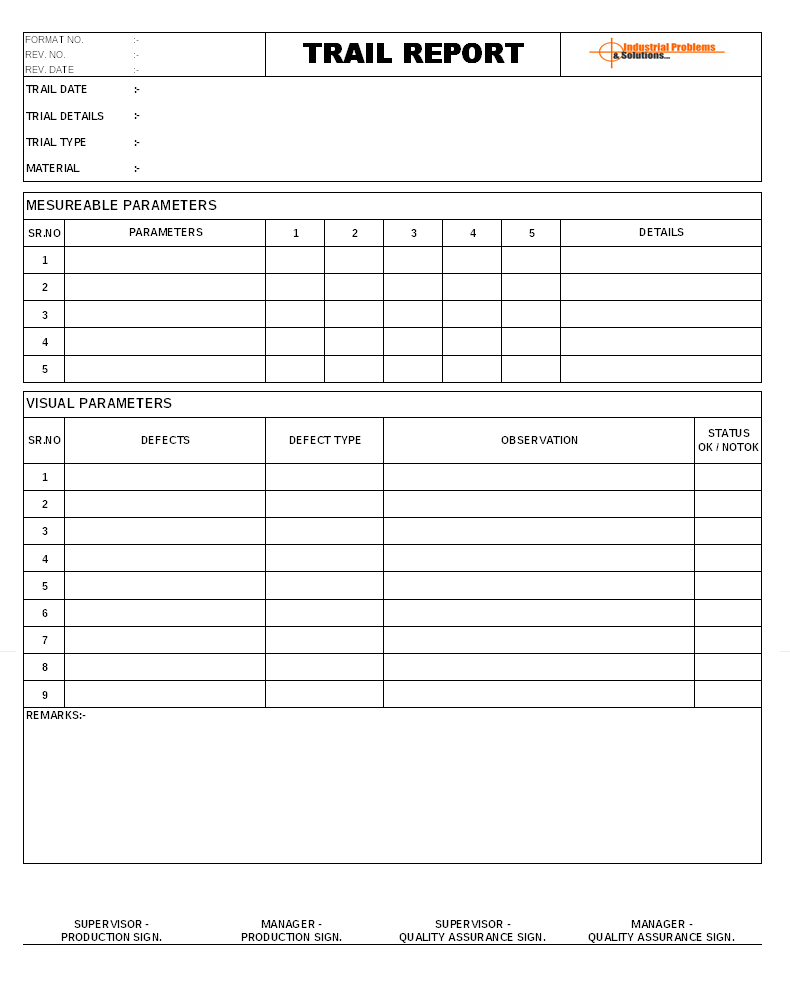

Product trail documents are prepared by quality department, and quality manager is responsible for preparation of product trail procedure and deployment in workplaces that required to maintain quality of product, the procedures and work instructions for manufacturing product are maintained by quality manager and also to monitoring on activity by testing records and process that conducted samples from various production stages and processes for verification as in-process inspection to ensure the product quality. The product trail process is conducted by two different types of inspection process, one is measurement parameters verification are conducted by qualified inspectors which are selected by quality manager, and second is visual parameters are verify of product, both are important and maintained product standards and its technical requirement accordingly. The process of the product trail and its manufacturing requirements are maintained quality head i.e. quality manager and production manager, during product trail in case any non conformity identified by quality inspectors that production manager is responsible for conduct those non conformity and immediate corrective actions should be taken to comply requirements of product quality and technical terms. The record of the product trail is managed by quality inspection, the pre-defined format is used by quality inspectors and record information as product trail process had conducted in the production lines. See picture below given as example format of product trail report for education purpose:

Product trail report format is used for recording information of product trail process, the format is provided by quality manager to quality engineer for managing records of process that conducted for trail on product to ensure the product quality as per product standards, technical requirements and customer specific requirements. The product trail report is managed to verification process in production lines, production manager is arrange the inspection i.e. product trail process and communicate with quality personnel for product trail in running batches at production lines, to manage the machinery and equipment, process stages and sequences of each process for improvement in product quality. The product trail report covered all product trail requirements that are visual parameter and measurable parameters of the product, in the visual parameters generally defects concern information are conducted and verified by quality inspectors by observe the process and product visually, hence the product measurable parameters are conducted on base of the three to five test on the values of parameters are defined as per product standards are conducted and verified, and the parameter tolerances are compared for further investigation as well as the rejection or approvals are defined on the tolerance maintained by product, in case the product visual and measurable parameters are not met the requirements that production manager should take immediate actions to maintain all the required procedures, setup and modification of the machinery and equipment, manpower manager, process sequences and bill of materials etc., are verified and immediate take the action as corrective and preventive actions.

The documentation of the product trail and concern reporting are maintained by quality inspectors and submitted to quality manager for further verification, approvals and analysis of product trail conducted in production lines, on base o the records and its concern documentation, quality manager is discuss with production manager for further clarification of product, standards, machinery and process setup and parameters. The documents are maintained and storage at quality department and its disposal are conducted as mentioned in documents and controls system.

—————————————————————————–

Download format in word document | Excel Sheet | PDF format

Product Trail Report

—————————————————————————–