Substitute material authorization process

Substitute material authorization process is conducted to setup substitute materials instead of setup materials as per customer requirements.

Substitute material authorization process is established for managing customer orders, product requirements, raw materials requirements for the processing materials in the manufacturing processes, and planning the materials as setup or template materials are used as per manufacturing processes, the system is allow to conducted substitute materials used for the producing final product with quality, to conducting this system used substitute materials instead of template materials which is regularly used to producing materials, and the system will be allow on authorization of the substitute materials processes and approvals of concern authority. The system process is maintain for systematically manage required materials for production lines to producing materials as raw materials are used substitute materials instead of regular used materials for particular product or sizes, and this system are manage substitute materials on base of the permission of authorized personnel. This system are used when the materials requirements are raised and the materials stock are not available, due to costing or any experiments for the product to improvement of quality or maintain product quality as per situation and condition of manufacturing processes.

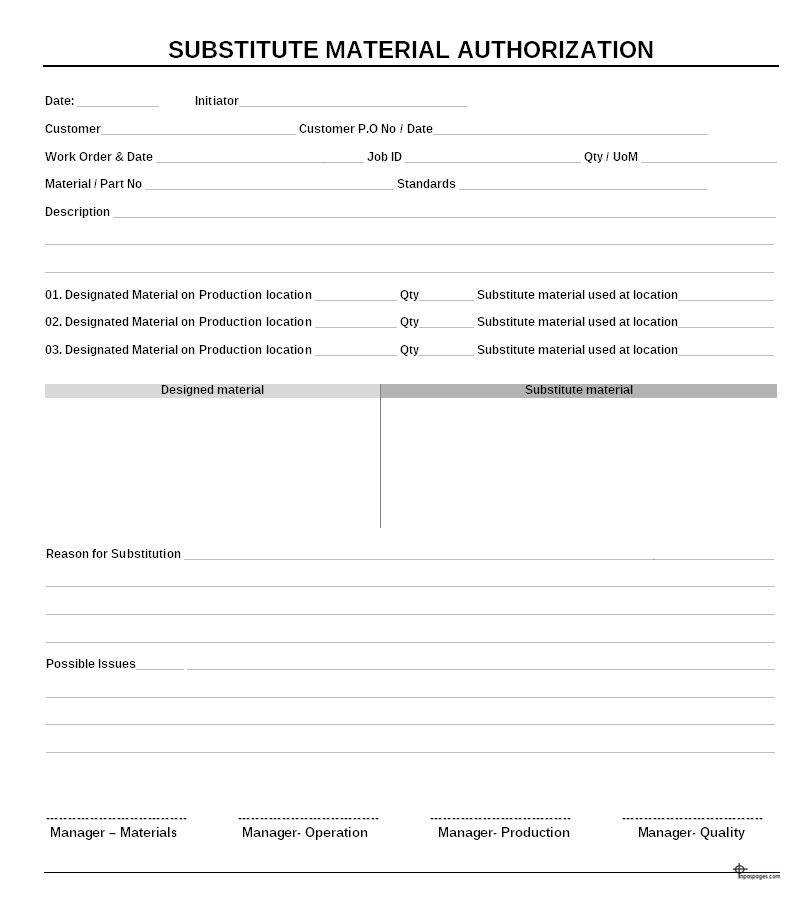

Substitute material authorization process is as and when process that deployed in system to managing material management, planning for the production lines and setup proper materials which can maintain standards, customer requirements and technical requirements of end application with quality product, the manufacturing processes should also able to proceeding the materials going to used as substitute materials. Substitute material authorization process is established, maintained and update by management, management representative is responsible for provides guidelines, instructions and procedures to easier for peoples to follows the system, and understand requirements of process. Management representative is also responsible for monitoring and controls over system with effective communication and reporting system. See picture below given as example format of substitute material authorization format used as document for approvals of substitute materials are used instead of template materials. See picture below for education purpose:

Substitute material authorization format for managing raw materials used for producing materials as per customer requirements, the process format is conducting records of regular / template raw materials which is designed materials for producing materials which is generally used for production for particular product / parts or sizes, and the substitute materials authorization format is managing substitute materials by setup and considering end application. The documentation is maintained, disposal and storage as per standards system adopted by management.