Line rejection documentation

Line rejection is results of inspection or identified fault in manufacturing processes or final inspection for verify product quality.

Line rejection is identify during manufacturing in-process or final quality inspection which is identified as raw material defects or vendor supply defects, are considered and manage in line rejection records. Line rejection is one type of rejection but its identify during manufacturing operations, generally this type of rejection is identify during operation, machine operation and other equipment operation that identified material fault in case due to vendor supply that all the materials are returned to vendor to considering as line rejection. All incoming raw materials which are used in manufacturing processes and supporting processes are inspected and tested for various parameters as identified in respective planning of control. Line rejection due to vendor faults is identified and details records in line rejection documentation. The materials along with line rejection document are forwarded to concern department for further clarification and for conformation of the vendor supplied.

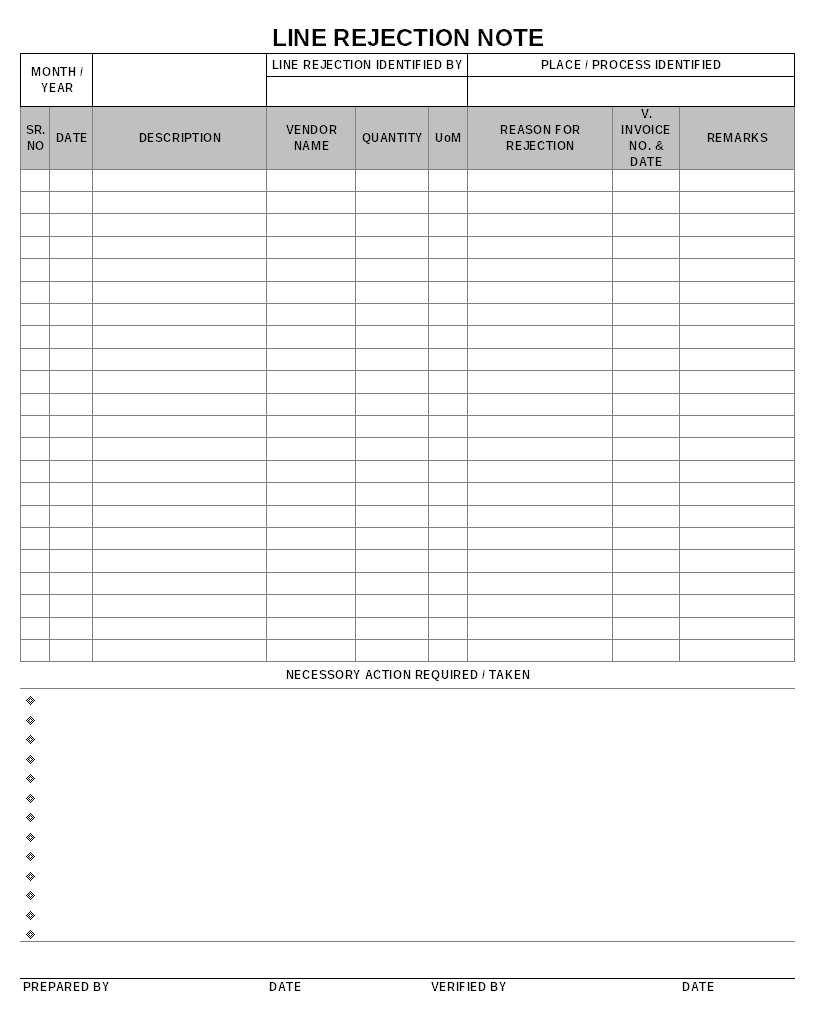

The line rejections documentation is established, maintained and update as per standard system, the records are maintained of in-process identified faults, due to machinery / equipment, human mistakes or due to vendor’s material supplies. To identify line rejection in in-process or in final quality testing of quality department, and quality manager is responsible for managing / arrangement of each inspection during in-process inspection, sampling plans and final product quality inspection, in case during the any process quality engineers are identify rejection and that reasons are due to vendor faults that entire batch / lot are returned to vendor as considering line rejection and same documentation are maintained. Details of non-conformances at receipt manufacturing process stage are recorded in incoming inspection report and supplier rejections in line are recorded in line rejection note, all the non conformance materials are returned back to vendor as per standards system & contracts terms. See picture below given as example format of line rejection note which is used for recording line rejection records, here as below given for education purpose:

Line rejection note is format used to recording rejection records which are raised due to vendor’s product faults / defects which are identified during in-process inspection or at final quality inspection stage. The records are maintained & update as per requirements of records and tracking for returning materials to vendor, the reasons are also conducted in the format to provide to concern vendor for its materials. The documents are maintained by quality department, hence the records are also handled by purchase department and records of line rejection, quality inspection and concern notes are maintained in separate to provide concern vendor.

——————————————————————————

Download format in word document | Excel Sheet | PDF format

Line rejection note

——————————————————————————