Inter quality control checking process

Inter quality control checking process is established to verification of materials are in processes to certify for further processing to assurance of product quality.

Inter quality control checking process is establish, maintain and update for checking in-process inspection to ensure the product quality during materials processing, verification of the processes and resources for improvement of product quality are part of inter quality control checking, the purpose inter quality control checking is to managing activities of inspection, documentations of quality and controls over activities for assurance of product quality supply for customer needs and end application requirements, the process is also conducted as standards requirements, product required standards and customer end application technical and specific requirements. inter quality control checking process is conducted by qualified quality inspectors, quality inspection team is managing records and activities in manufacturing processes, verify records and each process stage to ensure that product quality by conduct various tests required as per product standards, monitoring on quality processes for identify non conformance and each identified queries are provided to concern manger for process improvement.

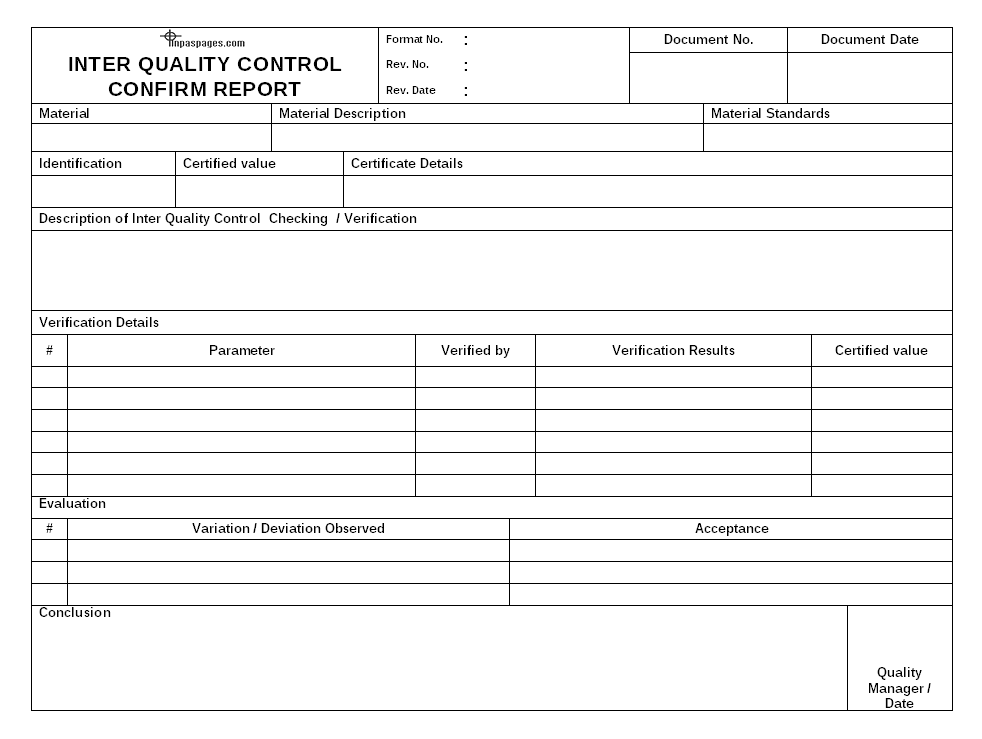

Inter quality control checking process is established by quality department and quality manager is responsible for conducting inter quality control checking processes, preparation of procedures and its concern documentation to department peoples are follows for maintain requirements of inter quality controls, quality manager is also responsible for selection of quality engineers / inspectors for conduct inter quality control checking processes, identify requirements to verification of resources and processes and reporting quality manager for further process, quality manger collecting information from reports and determine action plan for inter quality of product and processes, improvement of processes as per sequences and interactions in system and identify resources requirements for better performance. The documentation are used by qualified quality engineers / inspectors are managed and ultimately submitted to quality manager, quality inspection team is prepared report is inter quality control confirm report is the assurance of product quality, the report is maintained and update as per requirements of product standards and specifications, see picture below given as example format of inter quality control confirm report for education purpose:

Inter quality control confirm report is used in quality control inspection process, quality inspection team is prepared this report and submit to quality manager for the further actions to ensure that each process stage and its concern activities are managed, proceeded and conducted each materials in in-process accurately, in case any non conformance identified that quality inspection team is reporting for the same, the report is reviews by quality manager and provided information to concern department where non conformance is identified, concern department head is verify processes and actions plan prepared and implement at required. The documentation are handled and storage at quality department, and its each activities concern documentation are manage as per standards.

——————————————————————————

Download format in word document | Excel Sheet | PDF format

Inter quality control confirm report

——————————————————————————