Annual Calibration compliance Analysis

Annual calibration compliance analysis is conducted to ensure that each measuring equipment / instrument and devices are calibrated as per standards.

Annual calibration compliance analysis is study process to conducting information from various departments of each measuring devices, equipment and measuring instruments to ensure & conducting analysis on records of calibration to ensure that each calibration process is properly managed and used each equipment, instrument and devices are calibrated in the system. The process for the annual calibration compliance analysis is verify and conduct study of compliances of calibrations which is required to proper conducting calibration process for each equipment, instrument and devices are used for measuring product, process and supporting quality inspection that should be proper calibrated as per frequency defined in the system, and analysis are manage the each activity of calibration concern to identify malfunction of system of quality system that harm product quality. The purpose of establish annual calibration compliance analysis process in the system to ensure that the each measuring equipment, measuring instruments and measuring devices are documented for each department individual and same indexed in general records, requirements of standards for each measuring tools are managed for calibration, and its records are established and maintained by quality department, authority / responsible person is conducting each measuring devices, equipment and instruments for calibration as per frequency defined, in case of due calibration identified that what action are taken by management of quality and on rejection in calibration are removed from system as per standards requirements. The general requirements of calibration are managed and analysis records on annual base which records are conducted daily as well as monthly as per requirements and suitable for quality department.

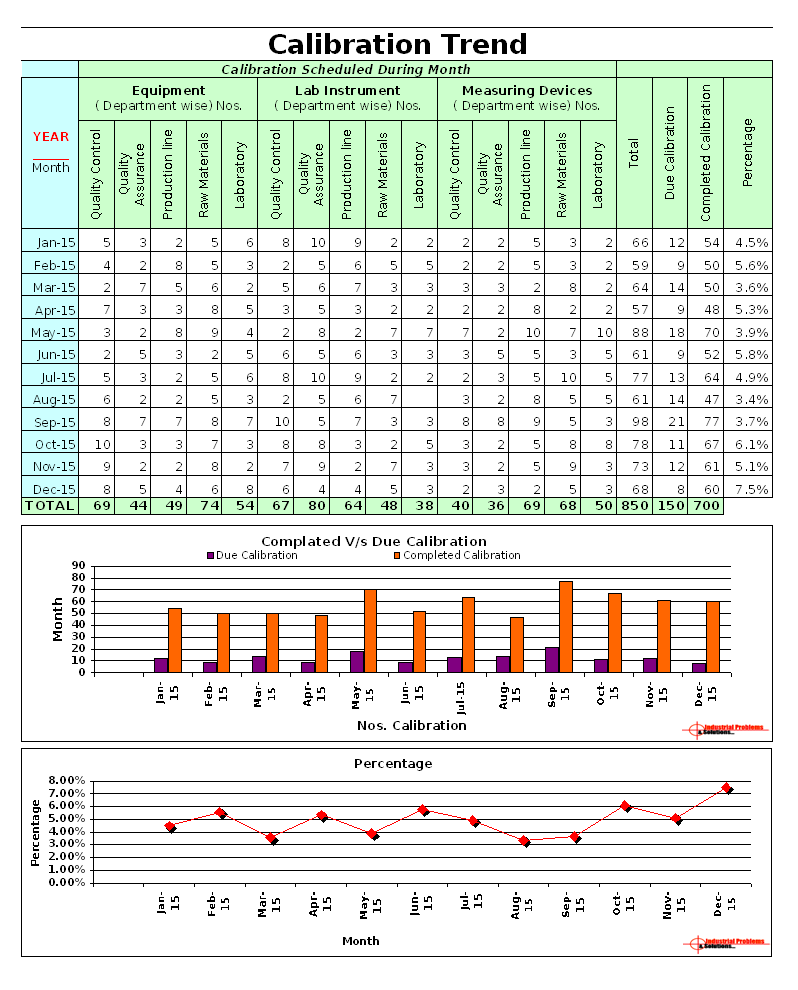

Annual calibration records are established, maintained and update by quality department, and quality manager is responsible for all concern activities to managing measuring equipment, measuring instruments and measuring devices that used in quality inspection, raw materials quality and measuring and in production lines that needs to proper calibration for maintain quality of product during each activity and assurance of measurement. For the conducting annual calibration compliance analysis, quality manager is establish calibration records and its trend to identify calibration compliance in various department, in the trend calibration date and its due dates are managed and further requirements are managed sapareately, like calibration standards and its individual measuring requirements as per equipment, devices and instruments are deployed in system and places where used for measuring product and supporting processes concern. See picture below given as example format of calibration trend for education purpose:

Calibration trend format is managed for conducting records and analysis trend of calibration due verses compliance of calibration during the month, the records are maintained annual basis, where all calibration concern records are maintained and update as per calibration are processes are conducted with various equipment, instrument and devices where installed in various department. The records are generated by concern supervisor and provided to quality manager for further analysis. The records for calibration trend and its analysis are managed records and improvement of activities to minimize failure to comply calibration requirements.

———————————————————————-

Download format in word document | Excel Sheet | PDF format

Calibration trend

———————————————————————-

Related: