Fixture inspection documentation for engineering

Fixture inspection documentation is established for conducting records of inspection process of fixture to ensure setup and condition of fixtures in engineering unit.

Fixture inspection documentation is established to collecting information of fixture inspection, activities are conducting during inspection processes and managing requirements, action plans for the improvement after the completion of the inspection process that need to determine action plan for managing requirements, non-conformance are handled for comply all requirements. In the fixture inspection generally verify visual and dimensionally verification of fixture to conducting inspection to ensure that the fixture is accurate and perform in regular task. The records are managed for the fixture inspection is to improvement of performance of fixture in workplace, the fixture inspection are generally conducted in engineering unit that frequently and quantitative requirements of fixture in workplaces.

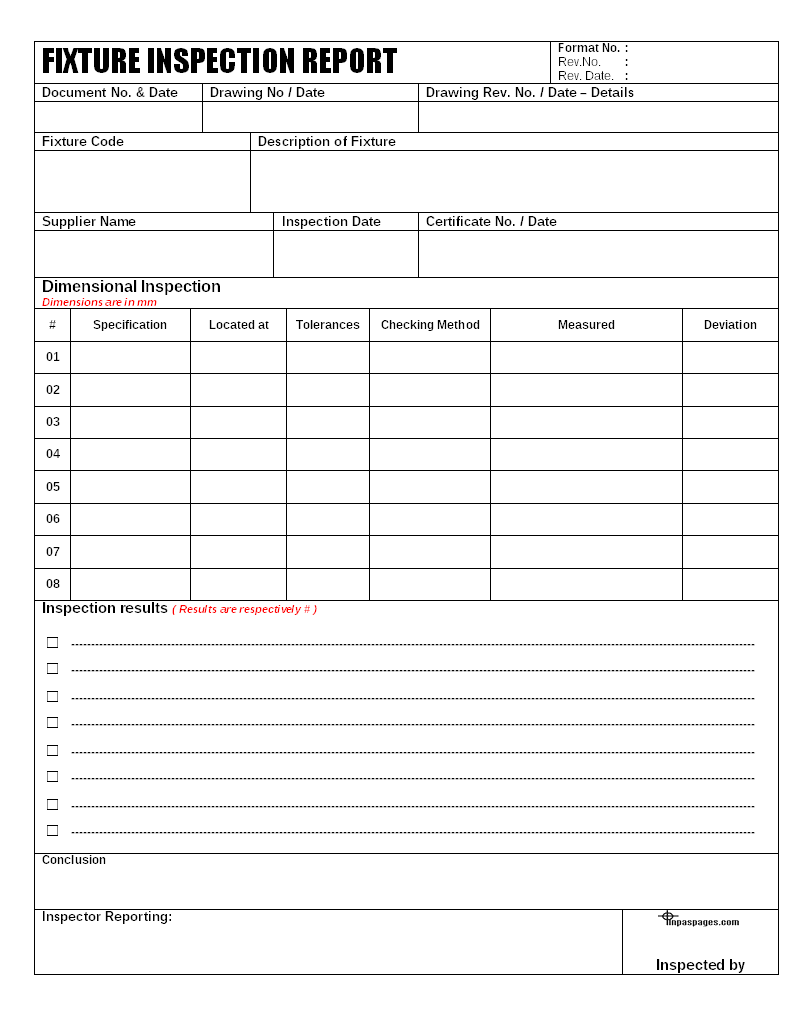

Fixture inspection documentation are maintained by quality department, and quality inspection team is responsible for conducting each quality concern requirements for managing and inspecting each part of the fixture by various techniques. The inspection process records are managed in the format is the fixture inspection report that all the requirements points are managed, where dimensional verification and inspection are conducted which important part of the fixture parameters requirements, see picture below given as example format of fixture inspection report for education purpose:

Fixture inspection report is prepared by qualified inspectors that verify each part of the fixture to ensure that the fixture can perform in regular task and provides quality and accurate works in workplace. Generally in the fixture inspection are managed to conducting dimensional inspection where all the required specification are verified by inspector, measuring each dimension as per fixture requirements and standard specification where tolerances are conducted and verified for identify variations / deviation in specific values. For the conducting fixture inspection, inspection teams is managed inspection process as per standard methods, and maintain stability requirements to identify proper values deviation of fixture to determine actions to improve accuracy of fixture. The records for the inspection process is managed and verified by authority. The records and documentations are prepared and handled by team which is maintained, update and disposal as per standard system of internal management system of company.

—————————————————————————

Download format in word document | Excel sheet | PDF format

Fixture inspection report

—————————————————————————

Related: