Raw material inspection process and documentation

Raw material inspection process is established & conducted to prevent inferiority raw materials from being consumed in manufacturing processes.

Raw material inspection process is established by quality department to conducting all incoming raw material which is used in manufacturing processes and used as prime materials to producing final product that all incoming raw materials should be needs to proper inspect to quality point of view, quality department is conducting raw material inspection procedure to preventive against poor quality materials being used in the manufacturing processes and eliminate possibility to used on any stage of manufacturing stages. Raw materials are used as hollow material that became a final product from it, so it’s necessary to conduct raw material for each testing that required as the standard requirements of as raw materials and for production / manufacturing standard requirements for raw materials and same for final product standard requirements should be matched to producing best quality materials. For the producing materials from raw materials and the raw materials are passing through various manufacturing process stages that each process stage having its requirements and its standard for procuring materials, hence raw materials should be perfect as required to pass in any stage without any damage or quality compromise.

What primary care needs to purchasing raw materials and inspections requirements?

The raw materials purchasing and taken in inspections is regular & important step which is normally conducted in manufacturing units, but before the purchasing the materials needs to care to considering basics that needs of the manufacturing processes, final product requirements & standard process sequences to managing materials with low cost and maintain proper quality of final product. At the time of purchasing of raw materials needs to calculate the stages of manufacturing processes, during the materials processes what should be yield, and how much waste will be generate on between manufacturing process and there is also important point that purchasing raw materials should be easily pass in manufacturing process to maintain standards.

See example:

Final Product: Round Seamless Steel tubes

General Process:

- Raw material cleaning

- Raw material Heat Treatment

- Raw material Cutting ( If required)

- Drawing Process – Semi Finish

- Straightening – Semi Finish

- Cutting Process – Semi Finish

- Lubrication – Finish

- Finish Product Quality Inspection

Now, How and what take care to purchasing raw materials (Mother hollow tubes) that can consume to making final product with law cost and also maintain quality. On purchasing of raw materials as above example, customer should take care:

- Raw materials basic defects – pitting, spots, rust etc..

- Expenses on raw material cleaning are being low at company end.

- At all stage of manufacturing processes should met the standard requirements like during raw material heat treatment process, tubes should not lost its quality mean its mechanical properties should react as to easier for drawing which is next coming process for tube manufacturing. Same in the drawing process material should not to be much hard to draw processes can load on machinery, mean heat treatment should be perfect at the place. During the purchasing also needs to consider the materials mechanical properties to possible minimize cost on each level.

- The product are producing for end application that tube’s chemical composition and mechanical properties should be perfects or maintained its tolerances required and met minimum and maximum values.

As above example is given to simplify subject of raw material purchasing and its inspection that as per product standards and requirements of end application.

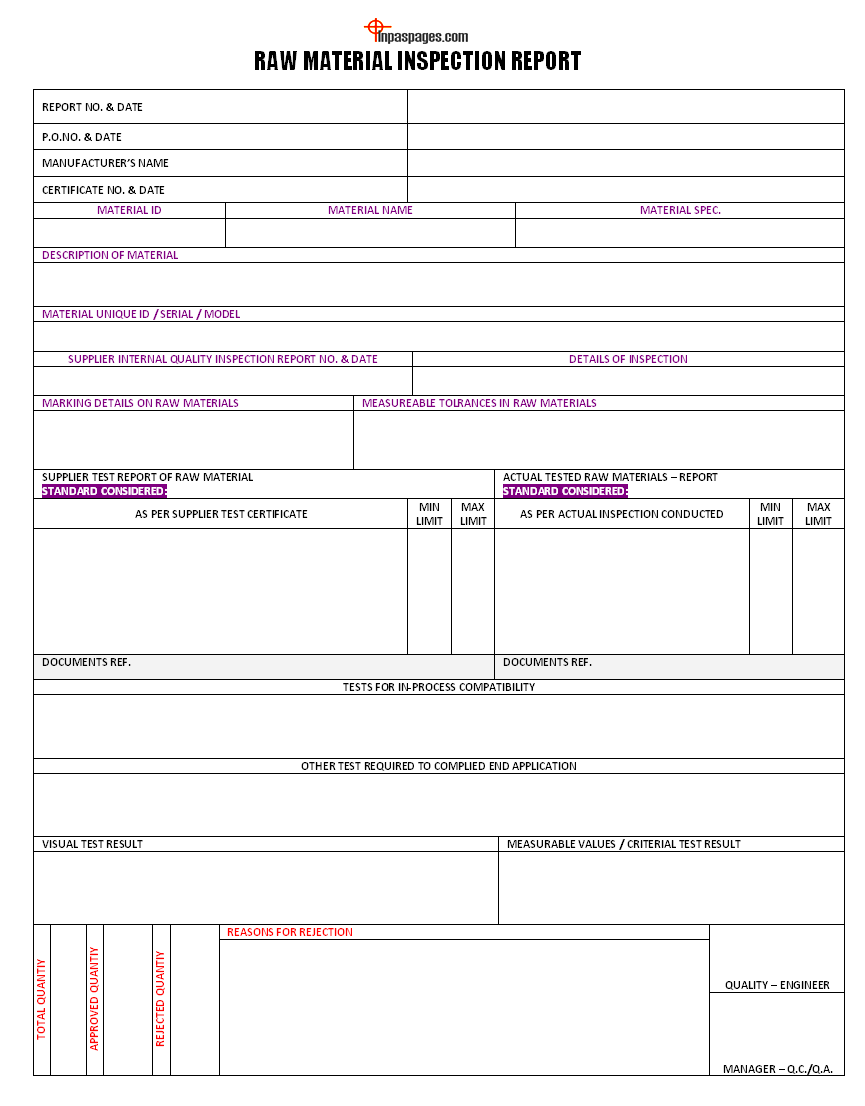

Raw material inspection process is established by quality department, on incoming each raw materials purchasing. Quality manager is responsible to prepare quality assurance plan and inspection process of raw materials as per standards of product and processes. Quality manager is conducting processes to test the raw material according to established inspection procedures, documentation and leveling for inspection passed materials. On conducting raw material inspection, quality department is responsible to confirm the materials has been inspected and can used for manufacturing processes. Quality manager is established quality plan to conduct inspection and provides processes instructions to concern quality inspectors, quality inspection team is prepared the document for conducting tests and quality inspection process, raw material inspection documents are conducted and reports are generated as result of inspection process, see picture below given as example format of raw material inspection report for education purpose:

Raw material inspection report is prepared by quality inspection team to recording information collected during raw material inspection, inspection report is submitted to quality manager for verification and quality manger is verify report and if any query raised that determine required action to eliminate any query raised with raw material, if the material is identify as rejected that those material is separately maintained in raw material storage as under rejected material head. When the raw material has been tested and approved by quality manger that material are identified as quality passed or any particular unique works to easier for every one to identify for used in production lines. The records of whole raw material inspection processes are maintained by quality department and used appropriate requirements, the documents which are concerned with raw material inspection and test are also given to supplier in case any raw material defects or query is identified. Raw material inspection report and its documents are conducted on each raw material purchase and maintained separately with identification numbers.

————————————————————————-

Download format in Word document | Excel Sheet | PDF format

Raw material inspection report

————————————————————————-