Total productive maintenance (TPM) audit

Total productive maintenance (TPM) audit is conducted to ensure established system of maintenance is properly handled and endure system compliance.

The procedures for total productive maintenance (TPM) audit is established for verify all maintenance activity and system which established for conducting activity of maintenance concern in company. The system deployed for identify non conformity of total productive maintenance activity and supporting system. Total productive maintenance activity is the system part of the standard works or method which makes works simple and organized, and its required documentation are improve the quality of maintenance activity, maintenance works productivity and also avoid possibility of work repeatability which is direct loss for the company and making a busy schedule of maintenance works.

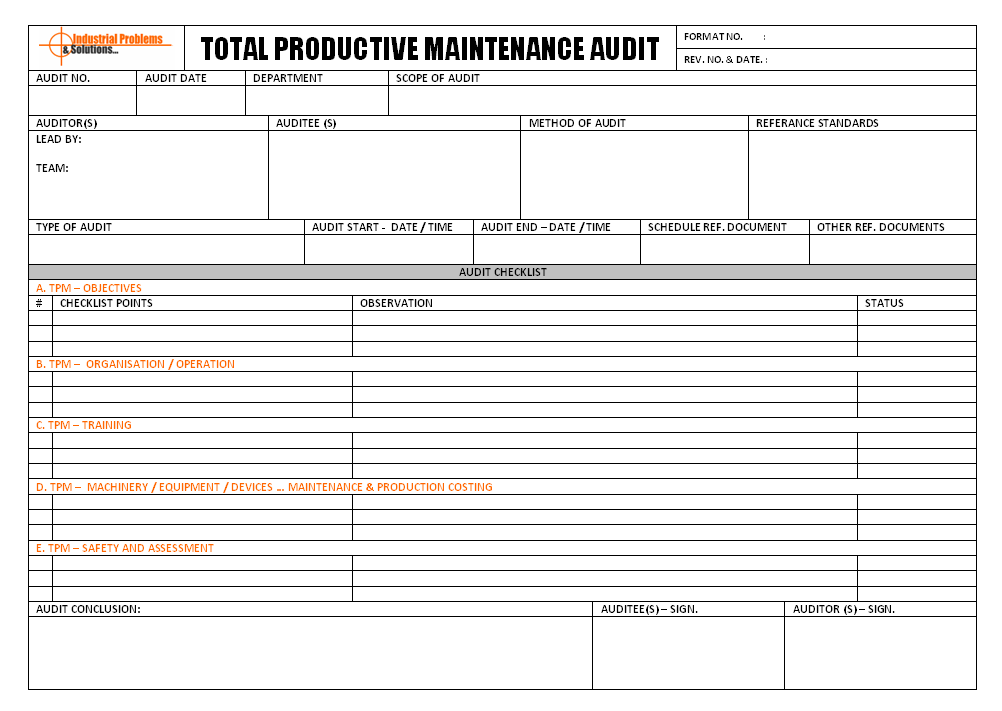

Total productive maintenance audit covered all the maintenance activity which are conducted as repairing, replacement of machinery, equipment etc.. Parts, services etc… Are major activity are need to audit on priority. It’s a management responsibility to decided qualified auditors for audit activity and processes of total productive maintenance to identify non conformity in maintenance system, hence maintenance head is responsible to conduct audit & comply all the non conformity identified, comment given by auditors and concentrate of auditor’s comments for improvement. For the conducting audit of total productive maintenance needs to preparation of documents and checklist to proper audit the areas at various locations, see picture below given format for example of audit format, the format given of total productive maintenance audit format as education purpose:

Total productive maintenance audit is conducted to verify some basic requirements and key elements of total productive maintenance, the audit is first verifying maintenance objective which is key objective for maintain maintenance activity are:

- No defects

- Reduction or eliminate Accidents

- Reduction in Speed losses

- No downtime of machinery, equipment and supporting tools

Auditor team is audit maintenance policy and its key objective as above mentioned for establish proper direction of audit, generally each equipment and machinery should manage and incorporated in policy and also should be correctly implemented in plant where auditors are verify records to identify any non conformity with it. Management should proper instructed and defined principle for provides proper guidelines and also determine yearly business plans. Auditors are verifying policy and key performance indicators to understand and implementation roots and causes of failures of activities.

In the management system, maintenance is important part that should be properly organized and conducted all the function and operation should be planed, in the audit or operations and organized structures system which all personnel of maintenance should duties are assigned and authorized personnel must proper managed equipment which supporting maintenance activity, audit team is also audit the organization system and how the job duties are assigned, responsible personnel are proper arranged and managed equipment is very important for maintenance. The system of maintenance should also actively engage with production and other important part of the manufacturing, and required accessory are managed, organized & easy for accessible.

Training is primary requirement of any department and maintenance department should also need to conduct all required training for its technicians and engineers. Audit team is very the all training concern document and verifying details that should provided all training are enough for maintenance activity, there are also important that each technicians and engineer should be certified for conducted maintenance works. Audit team audit document of certificate and skill assessment documents are important to verify effectiveness of training for maintenance division.

Audit team is prepared report and send to maintenance department for any non conformity raised that should be properly handed and complied all requirement for department improvement, all comments are generated during audit is valuable for maintenance team and should be committed for fulfillment.

————————————————————————–

Download format in word document | Excel Sheet | PDF format

Total Productivity maintenance audit

————————————————————————–