Product Status monitoring and records

Product status monitoring system is established to continuously monitoring activity of produced materials in manufacturing processes.

Product status monitoring system or product status monitoring procedures are established and deployed in manufacturing processes to frequently monitoring on activity of manufacturing processes, monitoring on product quality and its concern processes and checking product status to control product quality to identify non conformance raised during the processes. The system is deployed to check the status of product which is produced during manufacturing activity to support of standard methods and standard processes which are established for product quality improvement. Generally product status checking and monitoring are conducted on completion of any single stage or each stage of production completion, but the monitoring system is will be activate to conducting the situation of product in the processes to identify product quality treats during processes, and end of the process concern manager is inspecting all the documents and records of product status, manufacturing processes records and update the status to determine any further actions required, any possible changes in manufacturing processes or supporting processes to improvement in product.

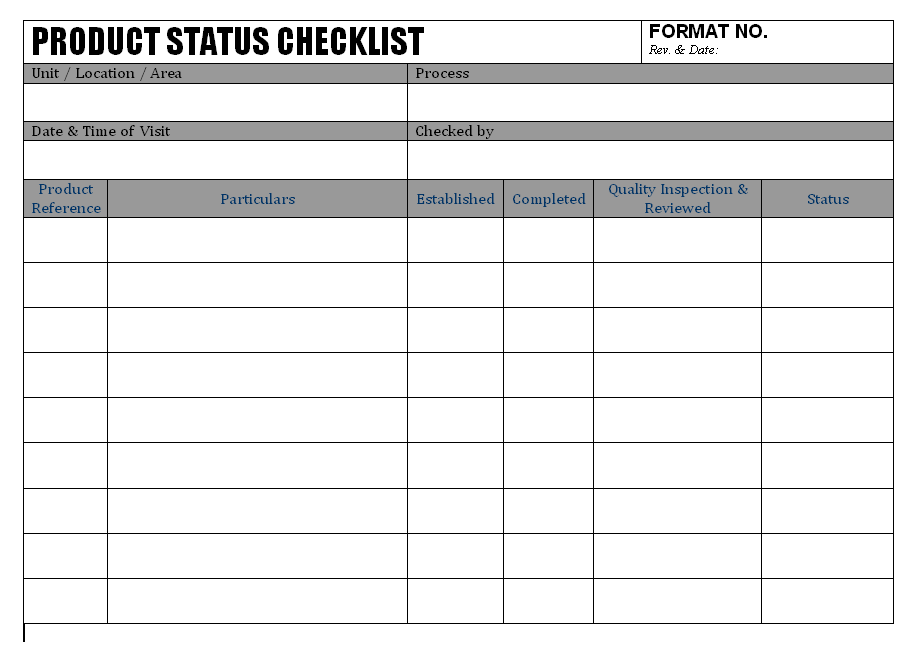

The purpose of product status monitoring system to determine actions on manufacturing processes and activity to improvement in quality of the product and works environment, the system support to managing activity of monitoring and conducting information form manufacturing processes. Product status monitoring system deployed by concern manager i.e. production manager to conducting information and analysis information of product concern. Manager conducting mostly quality concern information what reviewed by inspector for the product quality, on base of reviews manager conducting and understand possible change in management of production, manager is review information form the product status checklist which are maintained by concern supervisor and submitted to production manager on end of the day, see picture as below given reference format of product status checklist for education purpose:

Product status checklist is handled by department’s supervisor on daily basis, the information are collected and filled in the format on the completion of each production stage had been completed and information of the format is updated for the analysis and determine specific action for improvement.

——————————————————————–

Download format in word document | Excel Sheet | PDF format

Product status checklist

——————————————————————–