Non-conforming material management

Non-conforming material management to ensure material non-conforming is properly identified and particularly segregated to avert unintended utilize.

In manufacturing processes, due to some malfunctioning, raw material defects, mechanical problems or any miss instruction causes material non-conforming, to conduct those materials, handling, moving, identification, segregation and proper analysis of source causes to eliminate or minimize possibilities of non-conforming in manufacturing processes.

Non-conforming material management is establishment, maintain and update to ensure all the non-conforming products / materials are identified during manufacturing processes and supporting processes are identified and properly segregated, handled, storage i.e. properly managed as preventive conduct the nonconforming materials for inadvertent use in manufacturing processes along with approved materials. The purpose of non-conforming material management to provides an accuracy in routine works for expecting deliver methods for identification of non-conforming materials, controlling and dealing with non-conforming material in manufacturing processes by concern departmental peoples by fair guidelines / instructions through handling processes to minimize possibilities to raised non-conforming material percentages or trying to minimize level of non-conforming materials during processes, handling, moving and producing materials.

The system is guidelines and work instruction is suppose to peoples whose are working in manufacturing processes are functionally adequate to conduct all the task of manufacturing to producing quality best materials and its improvement of productivity, quality of works & sufficient knowledge can serve. Non-conforming material management is system provides techniques and method through works became easier & state to peoples get the idea what to do and what to avoid, the reasons of non-conforming material management is conducting each manufacturing processes and supporting processes to identify non-conforming products, identify root causes, sources of cause to eliminate possibilities of non conformance for minimize cost of manufacturing processes, there are one of the important is to eliminate possibilities to ship material with non-conformed product to customer that behind all the reputation of company is depended. Non-conforming material management is not just a system but its necessity of company to maintain markets & improve respectively.

Non-conforming material management procedure is established and applies to all manufacturing processes, operational parts of manufacturing units that materials is passing for regular tasks to conducting as produce, test or inspection tasks that’ all covered where detection of nonconformity in product & assuring to non-conforming materials are blocked in root of production for managing to further processes i.e. segregation & provisional storage for analysis and identification of re-works or re-inspection at location. Non-conforming material management is covered processes from raw material handling, movement, installation to in-processes till final product released. The non-conforming material management procedures / instructions and guidelines are established for all employees who are on detective mode or on operating processes for producing materials and every one is responsible for contribute and dedicated to provides its best in processes to elimination of passing non-conforming product during operative mode in manufacturing of materials, this is only to excessive operational responsibilities but the main responsibilities and accountability of identification, handle & analysis on non-conforming products are conducted & effectively mange by quality assurance and quality control appropriately, implementation of the process for non-conforming material management is both department appropriately contribute and effectively management, implementation and documentations to deem controls over sources of cause which is responsible for non-conforming.

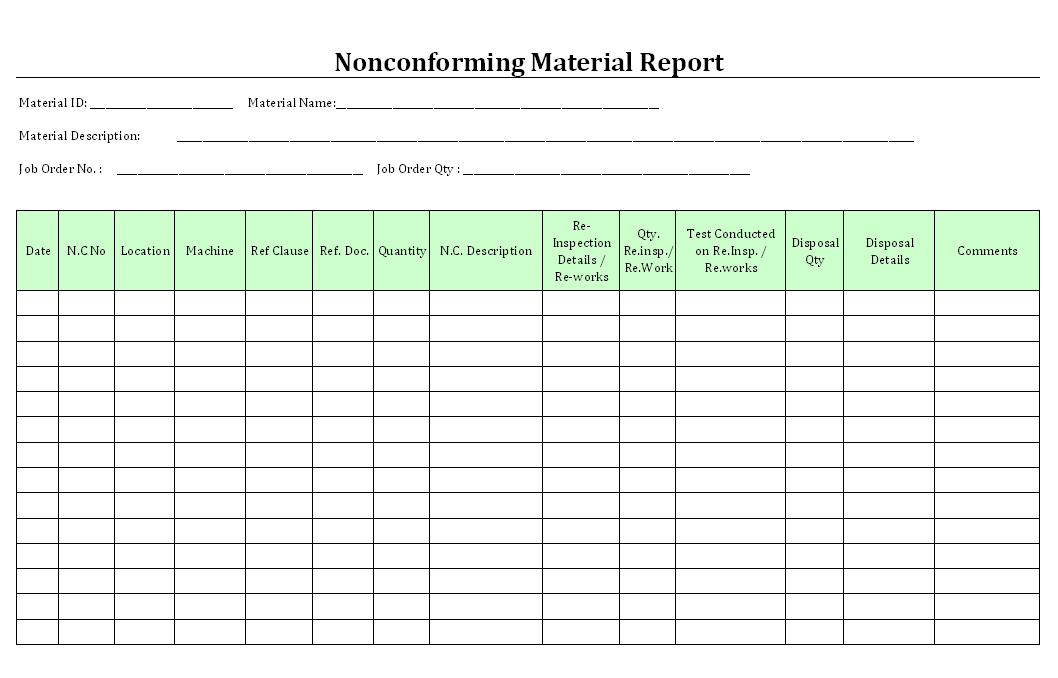

In operation of manufacturing processes in case any non-conforming product / materials are identified that should be proper documented and reporting to concern head is the part of system, to monitoring continuously on manufacturing processes by quality control team and during the operations any non-conforming materials are note that should be immediate temporary storage and remove from the manufacturing process system, there are also important that immediately report for the non-conforming material should be establish & reporting to head, the system allow to preparation of non-conforming material report for further actions, see picture below is given as reference of report which can directly apply in manufacturing if all the fields are suitable to manufacturing processes, each industry having its system and method that some addition and changes can required but overall it’s a sample format for educational purpose:

Document that helps to records information by collection from processes to handle proper task and analysis for improvement, documents which are conducted by manufacturing processes to support the system of non-conforming material management are:

- Non-conforming material report

- In-process inspections by quality controls and its concern documents

- Interactions reports, test and process notes

- Work instructions and guidelines for manufacturing process operators

- Conducting materials, movement and handling safety precautions

- Non-conforming materials reviews report

- Non-conforming materials disposition processes & documentations

- Non-conforming materials and record for re-work, re-inspections

As above given some major documents and reports are conducted for the manufacturing processes to managing non-confirming material management system. System is built by sequences of processes which semantically conducted in manufacturing processes along with its own procedures.

The procedure for non conforming material management, when any non-conformity is identified in manufacturing processes that should immediate tagged with any defined color for identification and should be segregated and labeled for non-conforming materials storage needs to move. Quality control team is conducting all non-conforming materials for analysis to identify material can possible to move for re-works, whenever the material is identified re-works that some primary stages mistakes can solved by re-works processes, quality control conform the all materials along with re-worked materials by inspection and remains re-worked materials are conducted as re-inspection respectively, and the materials can moved for next process.

————————————————————————

Download format in word document | Excel Sheet | PDF format

Non conforming material report in excel sheet download

————————————————————————