Hydrostatic test on components – Engineering standards

The purpose of the process is to check components / parts by hydrostatic testing as per quality standards and controls testing activities.

The process is conducted for inspecting components / parts by hydrostatic tests for quality inspection to comply requirements of engineering standards and the procedure to for proper controls on testing activities, the system is for the quality assurances and control over the activities of the testing on the components / parts to ensure quality of the components / parts conformity by hydrostatic testing. All the testing on the products / components / parts are conducted by quality department to ensure the components / parts quality and as per customer requirements to comply end application requirement. Hydrostatic testing is conducted to cover specification the standards hydrostatic testing to be performed on pressure as instructed by standards.

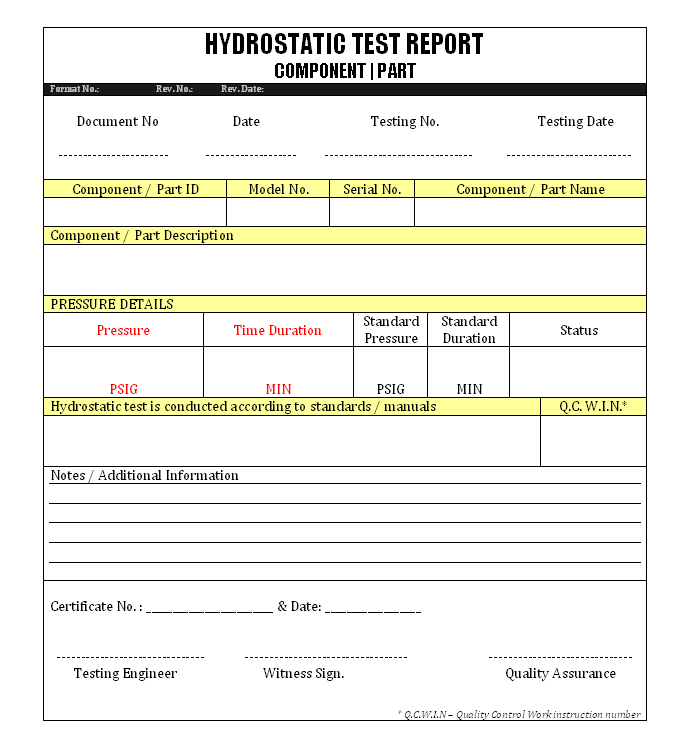

Hydrostatic test on components / parts are conducted by quality engineers to taken the references for the pressures, duration and requirements of other elements are as per engineering standards, quality engineers are responsible for the hydrostatic testing that each authorized quality engineer who is performed the task should be well training and certified for the conducting the testing. The process should be fully performed by quality control procedures; standard hydrostatic instructions which should met the requirements of engineering standards. Quality engineer is preparing document along with testing which should be conducted by witness observations, that can be third party or customers, the documents are preparation of hydrostatic test are very important, the documents are evidence of testing is conducted properly and at place. Generally after completion of the task hydrostatic testing, quality engineer is prepare hydrostatic testing report for the customers or internal used. The hydrostatic test report is evidence of testing there are also signed by witness, which can possible to appointed by customers or customer representative is available at the time of testing, so its important document for the both the parties. See picture below of hydrostatic test report for reference format given for education purpose:

The hydrostatic test is conducted to test the components / parts for the leaks detects, all components / parts shall be considered acceptable if no leaks are founds during the testing processes, as per standards and requirements whenever the tests are conducted successfully with the each component that quality engineer is prepare hydrostatic test report and issues concern department, third party or to customers. A test report certifying that the standard hydrostatic test is satisfactorily performed on pressure holding components shall be furnished to the customer upon request or standard requirement of components to conducting the standard pressure and duration of test. Generally hydrostatic test is conducted as per component standard requirements for pressure, durations and testing, but the customer has any additional requirements or little more pressure and duration which is possible to conducted with components that company is independent for the follow same, because the pressure, duration and testing requirements are generally mention in standards are minimum, if the company would like to go upon the limit that is advantage for components quality.

Hydrostatic testing with the product, components, parts etc.., and its procedures are different, the testing is conducted on base of particular products and as per defined standards, each product having its own mechanical properties and chemical compositions so it’s difficult to mentioned here procedures of any product.

———————————————————————-

Download Format in word document | Excel sheet | PDF format

Hydrostatic test report format in word document example download

———————————————————————-