Machine daily operation observation and documentation

Machine daily operation observation is monitoring system deployed to monitor activity of daily operation, time analysis for machine efficiency and productivity improvement.

Machine daily operation observations and its documentation are conducted for the improvement of machine efficiency and productivity, overall equipment efficiency percentage improvement by individual regular operation observations and reporting to enhancement in production, Machine daily operations, time analysis and waste analysis by monitoring on each process, supporting process for the controlling over the rejections and wastage in production line. In the machine observation, time management is on top priority to provide maximum time to machine for the increase productivity directly, hence by observation of collected information proper analysis is conducted and identify root cause and sources of rejection of material to minimize level or rejection as well as wastage / scrape on the machine for production improvement. Machine operation observation is conducted process wise, material wise when the machine is started to producing materials to shutdown the machine, during the time what activities are happened, which sub activity is conducting how much time, how much percentage of rejections and what is the level of scrape / wastage generating during the process and on which process there are most important factors and concern activity relative reasons are recording for the further analysis.

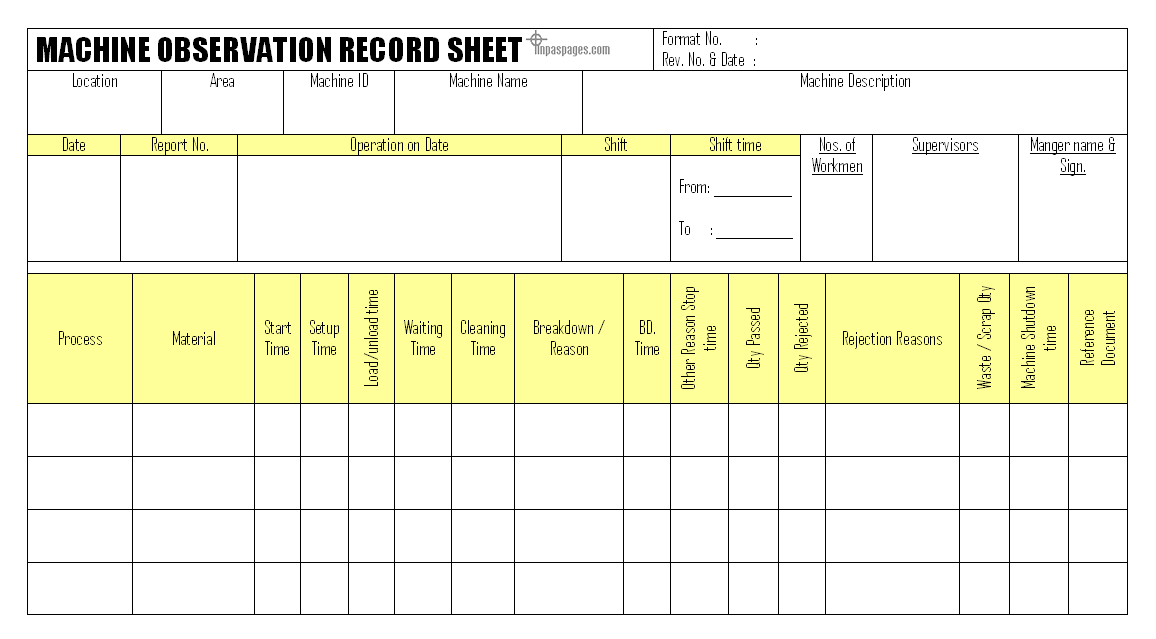

In machine daily operation observation covered all information concern of the machine and its process, machine process and used manpower, time and rejections / wastage is in center of observation and those are major factors that reducing level of efficiency of machine individually. The documentation of the machine activity is very important not just individual productivity improvement but also for the product quality, some time happen that to reach the customer delivery time target, machine is increasing speed or some change the parameters for the producing much amount of product in time frame which is non compliance for the product quality that its very important to frequently observation on machine and proper documentation is required to controls over the parameters of machine, level of the quality and its commitments are considered, see picture below for reference which is established for the recording and monitoring purpose to initially documentation is conducted:

Machine observation record sheet is collection of information which is comes by observation of machine regular operations, in the machine observation records are conducing the information individually, each machine separately machine observation record sheet is maintain for the individual performance analysis on end of the month or week for take the necessary actions on machine productivity improvement as per capacity of machine and information are collected of daily machine operation observation. Machine observation record sheet inserting the processes, material information, sub activity information, time analysis which is maintain from start to shutdown machine in the single shift, for analysis purpose the information of the each movement are conducted like Setup time, load and unloading time, when the machine is waiting for operation or materials are mentioned as waiting time, during operations some cleaning works are conduct that mention as cleaning time, in case of malfunctioning of the machinery, part of equipment which is waste time of operation of machine is separately manage as breakdown time and also respective reasons are inserting in report for documentation requirements. In the reporting quantity inserted, quantity passed and rejected quantity records are maintain for measuring the percentage of operation efficiency during the shift time, in case of rejections happen that describe rejection reasons are insert in report. On each machine is generating waste / scrap during general operations but the waste / scrap should be in acceptable level in case waste / scrap cross the acceptable level that need to immediate actions to minimize waste / scrap quantity on the operations, the information of the waste / scrape and its quantity are comes from daily machine observation record sheet which is maintain at the machine and same supervisor of machine should need to inserting values of waste and scrap in the report as possible measurements for analysis to control over it.

In the manufacturing units, documentations are very important for the internal system improvement, machine, equipment and process improvement by analysis of data collection during manufacturing processes and supporting activities, due to proper collection of information and analysis each system is possible to improve individually and that’s very important to each activity, event and required all information are correctly filled, analyze and effective actions are taken for growth of company. The documentation of the individual machine is one of the important parts of manufacturing division.

——————————————————————

Download format in word document | Excel Sheet | PDF format

Machine observation record sheet

——————————————————————