Operation quality inspection process

Operation quality inspection process conducted to ensure the operations are maintaining activities as standards, technical requirements & customer specifications to producing material.

Operational quality inspection procedure or process for managing quality inspection to ensure the material which is producing in the manufacturing facilities, processes and supporting activities is conducting by standard procedures, technical requirements for the process and product, specification requirements for the end applications are maintaining and all the documented procedures are controlled by the manufacturing authority. The quality inspection is not conducting product or material for the testing or any other inspection, operation quality inspection is for manufacturing processes, supporting process and activities which is concern with manufacturing to producing materials. Operation process is one type of layer inspection which whole the process sequences and interactions of process is included and same is inspect step by step to ensure the manufacturing processes are conducting the requirements of the product for the processes, sequences and interaction, the chain process and layer processes are in center of the operation quality inspection processes.

Operation quality inspection is conducting each operations are proceeded by manufacturing, all processes which are engaged in the producing the materials should be comply requirements of the manufacturing process standards and its requirements to ensure the product quality will be maintain and customers’ end application required criteria / acceptable level should maintain if the operation standards are maintained, In the operations quality inspection process major elements are:

Process requirements

Quality inspection team is conducting the inspection by the layer to layer, orders wise, sizes and specification of the product randomly to ensure that all the process requirements are complied, manufacturing processes activities are fully compatible to product manufacturing standard requirements and handling the product in the process.

Specifications

Manufacturing and its concern processes are on base of the specifications required to communicate process to process, sequences to sequences and concern activities, the standards is the method through process are established and works for producing materials in manufacturing units, process specifications and its visibilities is assurance of product quality and manufacturing cost concern. Quality inspection team is conducting required specifications to processes should follows and without any non conformity, specifications requirements should maintain in processes.

Standards / Technical requirements

The products and processes both are depends on the product standards and technical requirements, when the customer is place the order that customer given the required product standards and technical requirements to comply requirement of end applications, hence the manufacturing team should be need to define or defined standards and technical requirements for the manufacturing processes to producing the customer required product to meet the product standards and end applications. So its very important to each process should covered the product standards and technical requirements by the maintain process standards and technical requirements and quality inspection team is considering criteria for the same.

Frequency of inspection

For the operation quality inspection process is conducted as per quality head / production and management decided for the frequency to manage inspection in manufacturing processes, but the some time for the new product or new process, immediate inspection or frequency is amended as and when required, generally two inspection in month are sufficient if the manufacturing processes and product is regular.

Records

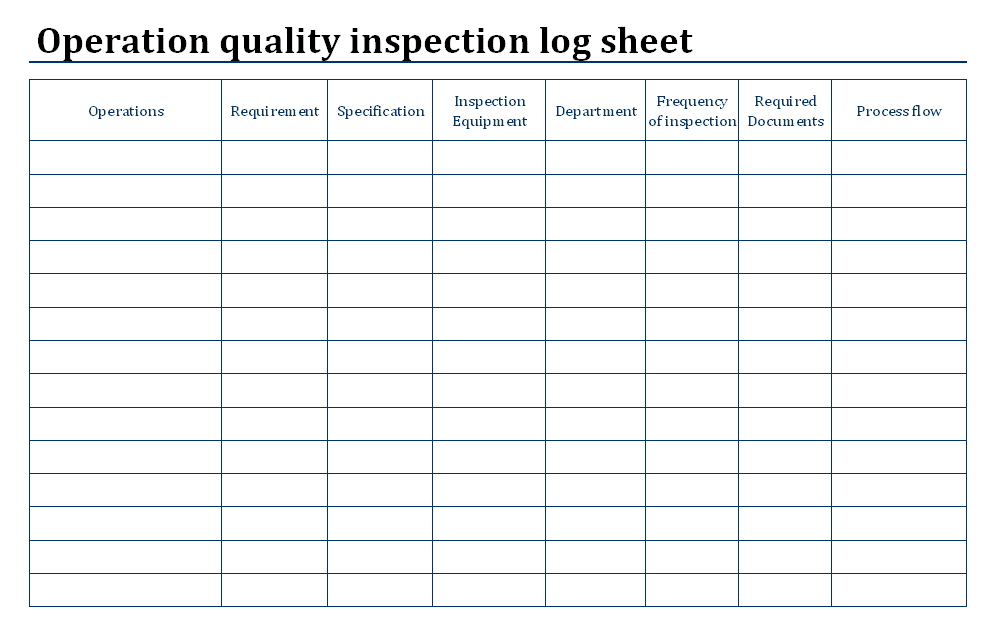

Operation quality inspection is conducted for the establish and maintain product’s required quality by sustain proper manufacturing processes and its controls by standards and technical requirements for the manufacturing process quality, the system of operation quality inspection is considered to whole process flow, all the process flow wise inspection, steps of the processes and concern supporting activities are also need to inspect, for the conducting the whole process required documentation, formats and record log which through possible to maintain and analysis information which are collected form the workplace, see picture above is used for the recording information of each stages, steps, process and supporting process operations.

————————————————————

Download format in word document | Excel Sheet | PDF format

Operation quality inspection log sheet

————————————————————